Preparation method of single teicoplanin components

A technology of teicoplanin and teicoplanin alone, which is applied in the field of separation and purification of teicoplanin single-component preparation, can solve the problems of low reusability of separation medium, strict requirements of separation system, and small preparation volume, and achieve The effect of controllable quality, simple and reasonable preparation process, and less solvent consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

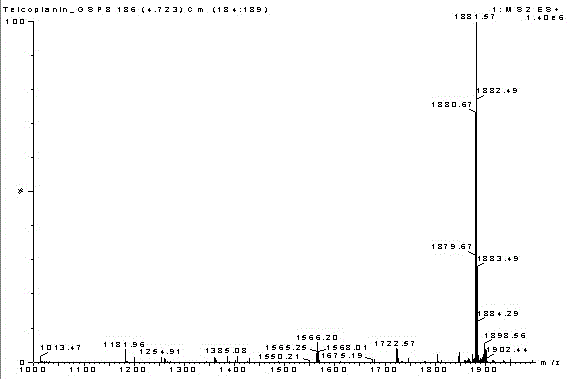

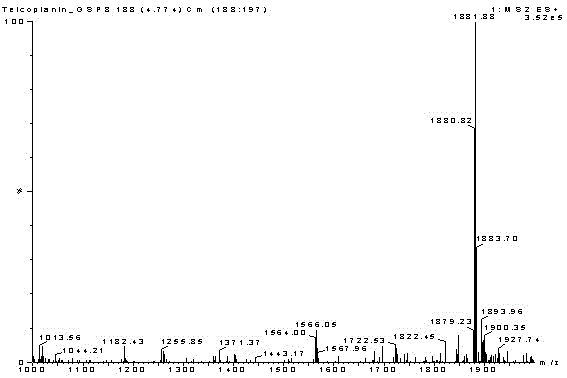

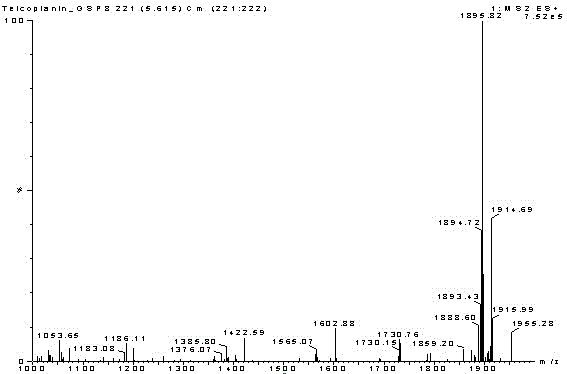

Image

Examples

preparation example Construction

[0050] A kind of preparation method of teicoplanin single component of the present invention, comprises the following steps:

[0051] Step 1) Pretreatment: under normal temperature conditions, add an alkaline solution to the teicoplanin fermentation broth, and adjust the pH to 11.0-13.0; preferably 11.5-12.5. The alkaline solution is sodium hydroxide solution or potassium hydroxide solution, preferably sodium hydroxide solution. The pH-adjusted fermentation broth is separated from solid and liquid by means of vacuum suction filtration, plate-and-frame filter press or centrifugation, and the obtained filtrate is adjusted to pH 7.0-7.5 with an acid solution to obtain a teicoplanin filtrate. The acid solution is one of hydrochloric acid, sulfuric acid or organic acid solution, preferably hydrochloric acid.

[0052] Step 2) Decolorization: introduce the teicoplanin filtrate into a macroporous decolorization resin for decolorization. The macroporous decolorization resin is one of ...

Embodiment 1

[0062] Take 5 L of teicoplanin fermentation broth, and the fermentation unit is 2380 μg / mL. Adjust the pH of the fermentation broth to 11.5 with sodium hydroxide solution, and vacuum filter. The filtrate was adjusted to pH 7.0 with hydrochloric acid solution, and then passed through a macroporous resin LX-98 column (loading capacity: 1200 mL) at a flow rate of 2 BV / h for decolorization. The decolorization solution is introduced into the macroporous resin HZ801 column (capacity is 1200mL) at a flow rate of 2BV / h for adsorption and enrichment. After the adsorption is completed, it is first washed with 15% methanol aqueous solution, and then desorbed with 40% methanol aqueous solution. The desorption flow rate is controlled at 0.5BV / h, when HPLC detects that teicoplanin flows out, start to collect the desorption solution. After the desorption is completed, the desorbed solution is concentrated under reduced pressure at 50° C. until the concentration of teicoplanin is 80 g / L, and...

Embodiment 2

[0064] Take 10L of teicoplanin fermentation broth, and the fermentation unit is 2700 μg / mL. Adjust the pH of the fermented broth to 12.5 with potassium hydroxide solution, and filter by centrifugation. The filtrate was adjusted to pH 7.5 with sulfuric acid solution, and then passed through a macroporous resin LSA-700B column (3000 mL capacity) at a flow rate of 2 BV / h for decolorization. The decolorization solution is introduced into the macroporous resin HZ816 column (3000mL capacity) at a flow rate of 2BV / h for adsorption and enrichment. After the adsorption is completed, it is first washed with 20% ethanol aqueous solution, and then desorbed with 50% ethanol aqueous solution. The desorption flow rate is controlled at 0.5BV / h, when HPLC detects that teicoplanin flows out, start to collect the desorption solution. After the desorption is completed, the desorbed solution is concentrated under reduced pressure at 50° C. until the concentration of teicoplanin is 100 g / L, and ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com