Automatic energy recovering device for driving axle of heavy-duty truck

A recovery device, a technology for heavy-duty vehicles, applied in electric vehicles, engine-driven traction, brakes, etc., can solve the problems of high maintenance and repair costs, heavy brake system loads, and short service life, and achieve convenient disassembly and maintenance. The effect of improved braking efficiency and ease of manufacture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

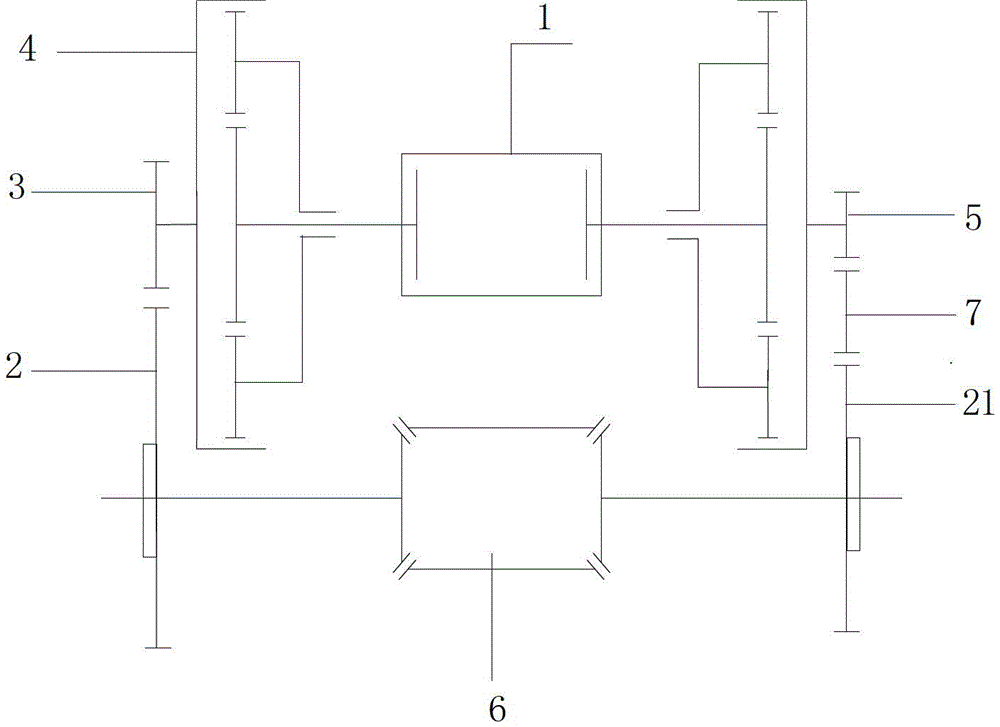

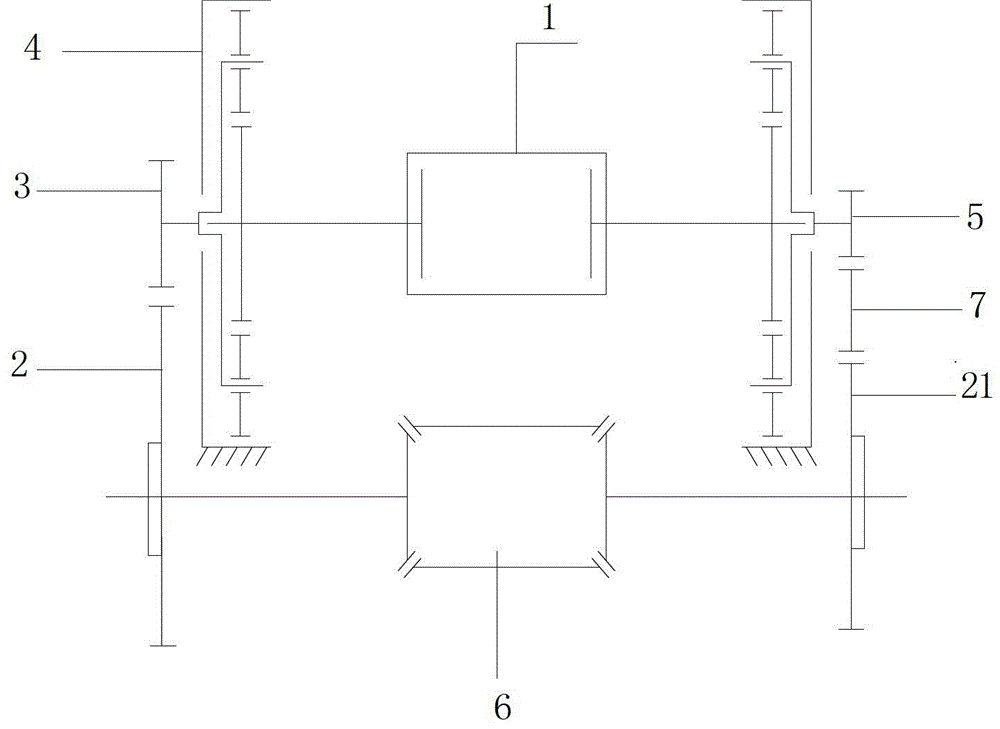

[0018] figure 1 Is a simplified structural diagram of the present invention in which the planet carrier in the planetary gear system is fixed, figure 2 It is a simplified structural diagram of the present invention in which the inner ring gear in the planetary gear system is fixed. As shown in the figure, the heavy-duty vehicle drive axle brake energy recovery device of this embodiment includes a generator 1 installed on a frame and a wheel system The rotational speed during the driving process is transmitted to the transmission device of the generator 1, the transmission device includes a driving gear that can be disengaged and disengaged from the wheel and axles, and the driving gear meshes and drives the generator to generate relative movement between the rotor and the stator. Driven gear.

[0019] In this embodiment, the stator of the generator 1 is arranged in a housing in a rotatable manner around the stator axis, the driving gear and the driven gear are two respectively, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com