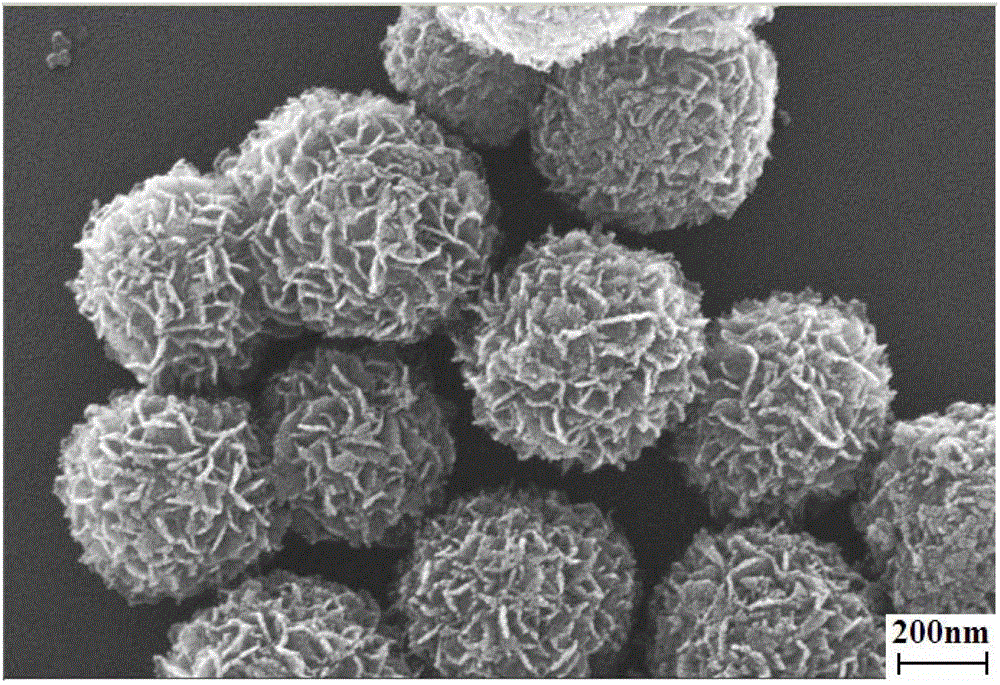

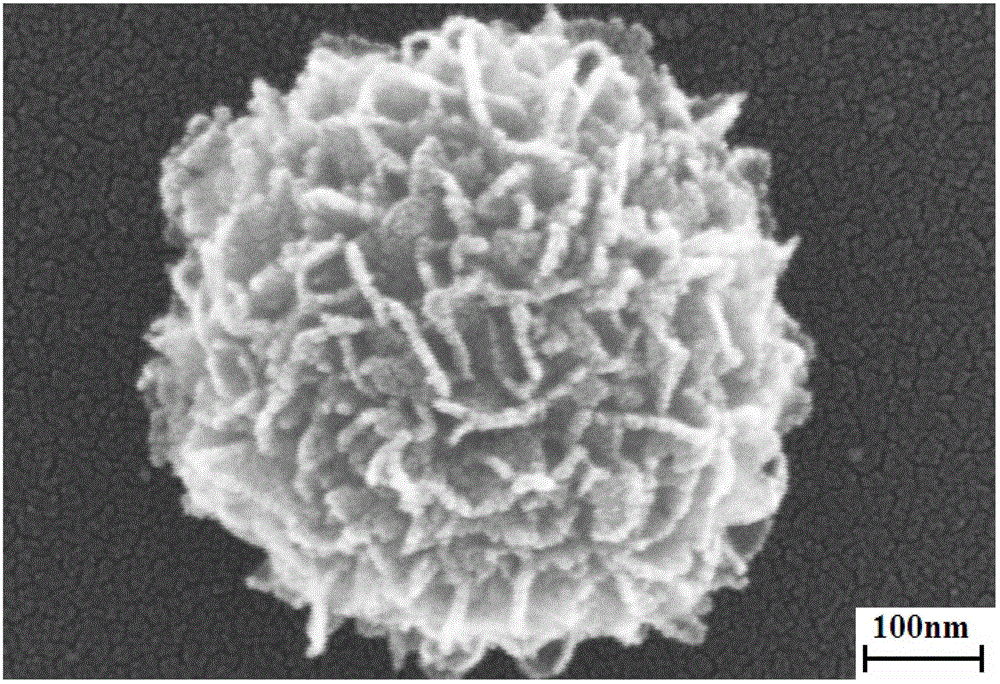

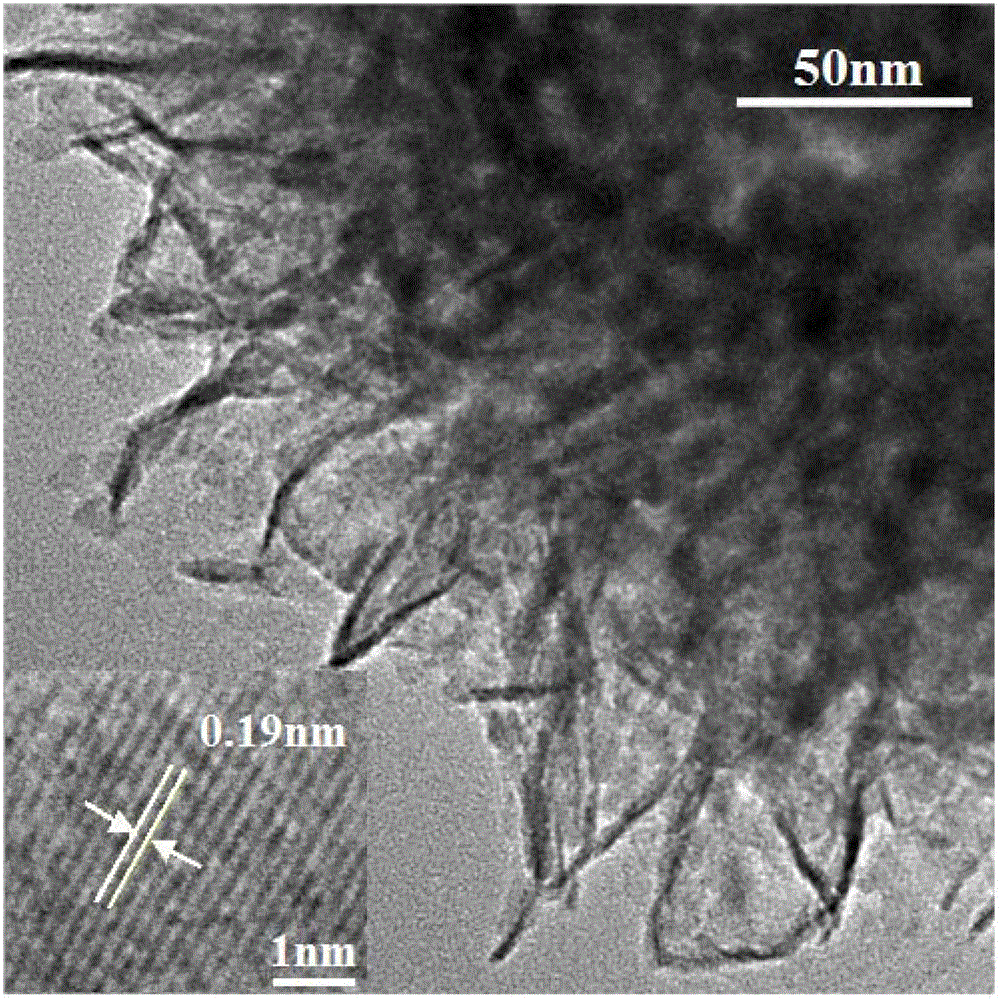

(001) surface exposure fe (ferrum) doping tio2 (titanium dioxide) multi-stage catalyst and preparation method of fe doping tio2 multi-stage catalyst

A titanium dioxide and catalyst technology, which is applied in the field of multi-level structure nanomaterial catalysis to achieve the effects of high specific surface area, simple and easy steps, and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Preparation of catalyst precursor:

[0025] Accurately measure 71 ml of isopropanol (IPA) in a beaker, add 0.05 ml of diethylene triamine (DETA) and stir gently for 3 minutes. After stirring, add 3.35 ml of titanium isopropoxide ( TIP) is added to the above solvent to obtain a mixed solution. Accurately weigh 0.0027 g FeCl 3 ·6H 2 Dissolve O in the mixed solution and disperse it ultrasonically for 3 minutes. Transfer the mixed solution to a 100 ml autogenous pressure reactor, crystallize at 200°C for 24 hours, cool to room temperature after the reaction, then wash the reaction precipitate with absolute ethanol 3 times, and dry at 60°C after washing 12 Hours, get light yellow powder, recorded as 0.1%~Fe-TiO 2 NSHS-as, 0.1% is metal ion Fe 3+ With Ti 4+ 的molar ratio.

[0026] 2. Preparation of catalyst:

[0027] The catalyst precursor obtained is 0.1%~Fe-TiO 2 NSHS-as, in a tube furnace in an air atmosphere at a heating rate of 1°C / min to 400°C, calcined for 2 hours, the...

Embodiment 2

[0030] 1. Preparation of catalyst precursor:

[0031] Accurately measure 71 ml of isopropanol (IPA) in a beaker, add 0.05 ml of diethylene triamine (DETA) and stir gently for 3 minutes. After stirring, add 3.35 ml of titanium isopropoxide ( TIP) is added to the above solvent to obtain a mixed solution. Accurately weigh 0.0054 g FeCl 3 ·6H 2 Dissolve O in the mixed solution and disperse it ultrasonically for 3 minutes. Transfer the mixed solution to a 100 ml autogenous pressure reactor and crystallize it at 200°C for 24 hours. After the reaction, cool to room temperature naturally, and then wash the reaction precipitate 3 times with absolute ethanol, and then dry it at 60°C after washing 12 Hours, get light yellow powder, recorded as 0.2%~Fe-TiO 2 NSHS-as, 0.2% is metal ion Fe 3+ With Ti 4+ 的molar ratio.

[0032] 2. Preparation of catalyst:

[0033] The obtained catalyst precursor 0.2%~Fe-TiO 2 NSHS-as, in a tube furnace in an air atmosphere at a heating rate of 1°C / min to 400°C,...

Embodiment 3

[0035] 1. Preparation of catalyst precursor

[0036] Accurately measure 71 ml of isopropyl alcohol (IPA) in a beaker, add 0.05 ml of diethylenetriamine (DETA) and stir gently for 3 minutes. After stirring, add 3.35 ml of titanium isopropoxide ( TIP) is added to the above solvent to obtain a mixed solution. Accurately weigh 0.0135g FeCl 3 ·6H 2 Dissolve O in the mixed solution and disperse it ultrasonically for 3 minutes. Transfer the mixed solution to a 100 ml autogenous pressure reactor, crystallize at 200°C for 24 hours, cool to room temperature after the reaction, then wash the reaction precipitate with absolute ethanol 3 times, and dry at 60°C after washing 12 Hours, get light yellow powder, denoted as 0.5%~Fe-TiO 2 NSHS-as, 0.5% is metal ion Fe 3+ With Ti 4+ 的molar ratio.

[0037] 2. Preparation of catalyst:

[0038] The obtained catalyst precursor 0.5%~Fe-TiO 2 NSHS-as, in a tube furnace in an air atmosphere at a heating rate of 1°C / min to 400°C, calcined for 2 hours, the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com