Cored wire for preparing FeCrB coating through electric arc spraying and coating preparation method

A technology of powder core wire and arc spraying, which is applied in the direction of coating, metal material coating process, fusion spraying, etc., and can solve the problems of reduced bonding strength and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

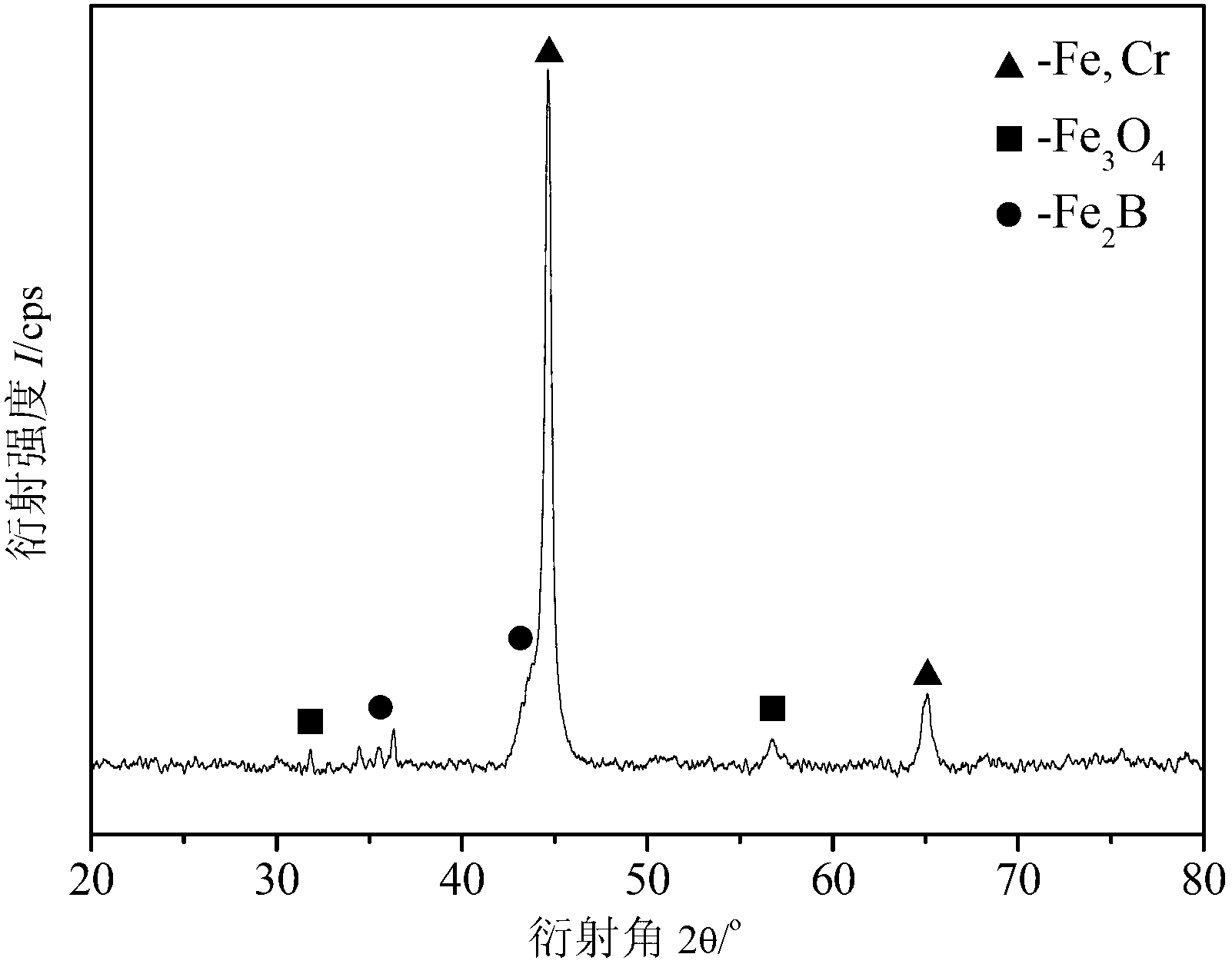

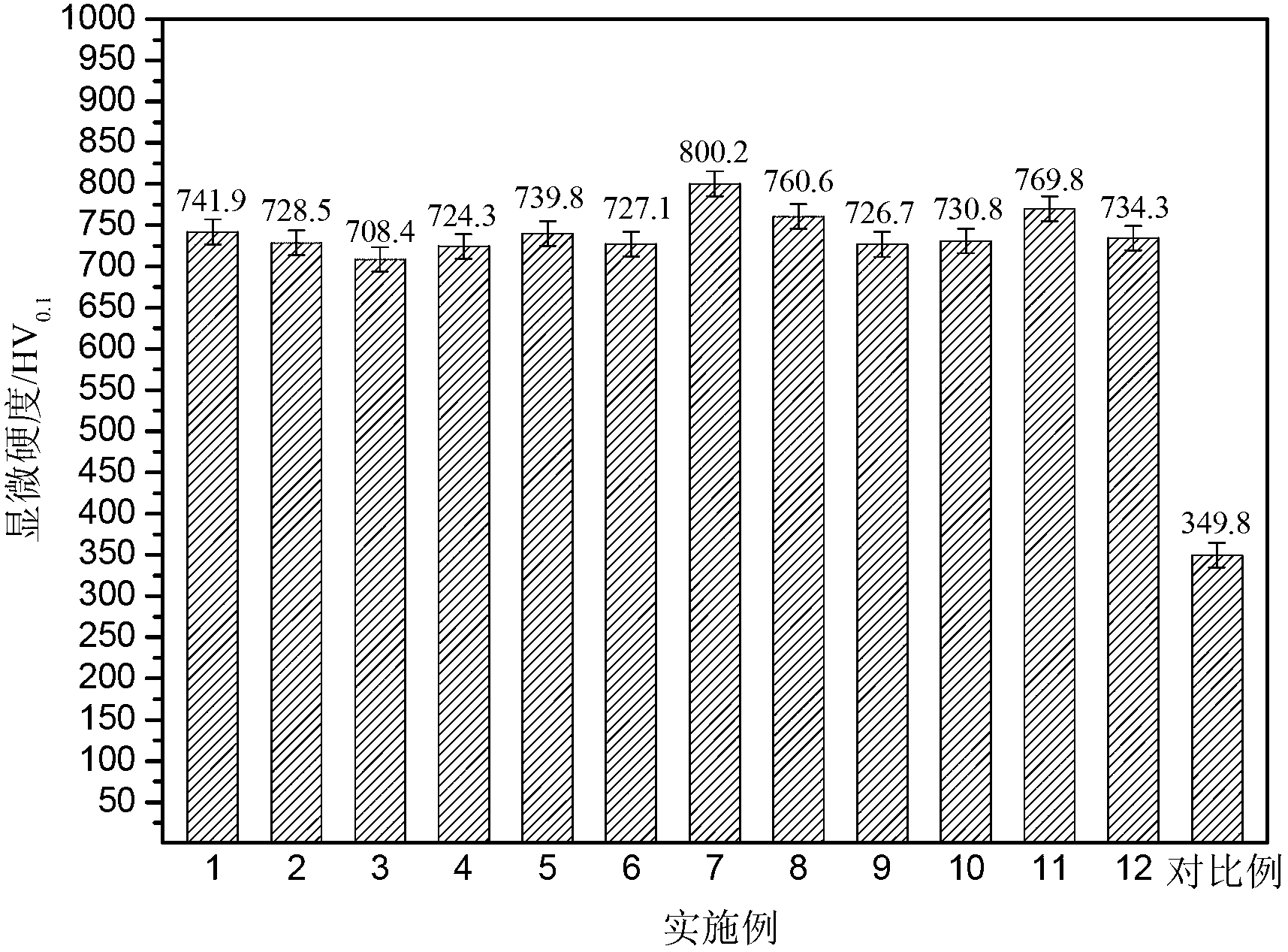

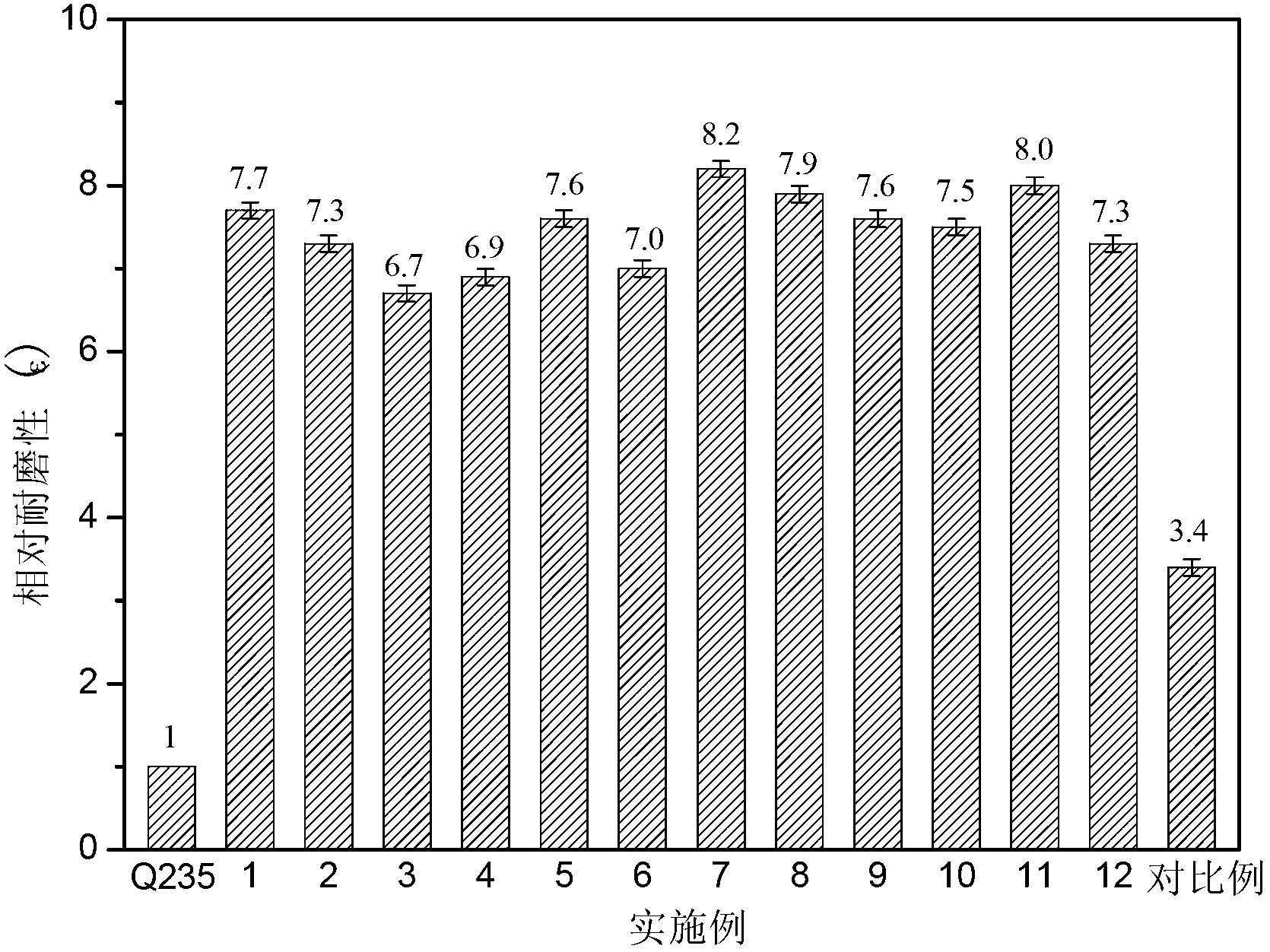

Embodiment 1

[0029] The material and mass percentage of the powder core are: chromium powder: 20.3%; boron carbide powder: 15%; iron powder: the balance; filling rate: 32%, rolled powder core wire. Process parameters used for coating preparation: voltage 26-30V; current 180-200A; spraying distance 190mm; compressed air pressure 0.4-0.5MPa. The mass percentage of each component in the obtained coating is: Cr: 18wt.%; B: 4wt.%; Fe: balance.

Embodiment 2

[0031]The material and mass percentage of the powder core are: chromium powder: 20%; boron carbide powder: 13.7%; iron powder: the balance; filling rate: 33%, rolled powder core wire. Process parameters used for coating preparation: voltage 30-34V; current 200-220A; spraying distance 200mm; compressed air pressure 0.5-0.6MPa. The mass percentage of each component in the obtained coating is: Cr: 18wt.%; B: 4wt.%; Fe: balance.

Embodiment 3

[0033] The material of the powder core and its mass percentage are: chromium powder: 25.8%; boron carbide powder: 20%; iron powder: the balance; filling rate: 34%, rolled powder core wire. Process parameters used for coating preparation: voltage 26-30V; current 180-200A; spraying distance 190mm; compressed air pressure 0.4-0.5MPa. The mass percentage of each component in the obtained coating is: Cr: 20wt.%; B: 6wt.%; Fe: balance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com