Kitchen waste disposal method and anaerobic fermentation reaction device

A technology of food waste and treatment method, which is applied in the field of fermentation, to achieve the effect of high sludge load rate, small biogas residue production, and improved gas production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

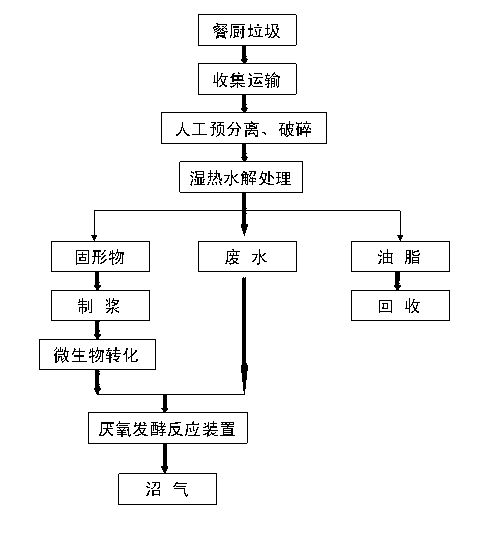

[0037] A method for treating food waste, comprising the following steps:

[0038] (1) Screening and crushing of food waste: Classify the collected food waste according to organic matter and inorganic matter, remove metal, plastic, glass bottles and other sundries, and crush the separated organic matter into fine particles with a particle size of 8mm. get mixed material;

[0039] (2) Moist thermal hydrolysis treatment: the mixed material obtained in step (1) is pumped through pipelines to a humid heat reaction device for cooking at a temperature of 160°C for 80 minutes to obtain a mixture of solids, waste water, and oil;

[0040] (3) Solid-liquid separation: send the mixture obtained in step (2) into a centrifuge, and perform solid-liquid separation on the wet heat treated material by means of centrifugal pressure filtration;

[0041] (4) Oil separation: the liquid part separated in step (3) is separated by gravity and centrifugation, the oil is recovered, and the waste water ...

Embodiment 2

[0048] A method for treating food waste, comprising the following steps:

[0049] (1) Screening and crushing of food waste: Classify the collected food waste according to organic matter and inorganic matter, remove metal, plastic, glass bottles and other sundries, and crush the separated organic matter into 0.7mm fine particles to obtain a mixture material;

[0050] (2) Moist thermal hydrolysis treatment: the mixed material obtained in step (1) is pumped through pipelines to a humid heat reaction device for cooking to obtain a mixture of solids, waste water, and oil;

[0051] (3) Solid-liquid separation: send the mixture obtained in step (2) into a centrifuge, and perform solid-liquid separation on the wet heat treated material by means of centrifugal pressure filtration;

[0052] (4) Oil separation: the liquid part separated in step (3) is separated by gravity and centrifugation, the oil is recovered, and the waste water is used for standby;

[0053] (5) Pulping: hydration ...

Embodiment 3

[0058] A method for treating food waste, comprising the following steps:

[0059] (1) Screening and crushing of food waste: classify the collected food waste according to organic matter and inorganic matter, remove metal, plastic, glass bottles and other sundries, and crush the separated organic matter into fine particles to obtain mixed materials;

[0060] (2) Moist thermal hydrolysis treatment: the mixed material obtained in step (1) is pumped through pipelines to a humid heat reaction device for cooking at a temperature of 160°C for 80 minutes to obtain a mixture of solids, waste water, and oil;

[0061] (3) Solid-liquid separation: send the mixture obtained in step (2) into a centrifuge, and perform solid-liquid separation on the wet heat treated material by means of centrifugal pressure filtration;

[0062] (4) Oil separation: the liquid part separated in step (3) is separated by gravity and centrifugation, the oil is recovered, and the waste water is used for standby;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com