Processing technology of bead-shaped black tea

A processing technology and black tea technology, applied in the field of bead-shaped black tea processing technology, can solve the problems of no bead-shaped black tea, difficulty in rolling and shaping of tea leaves, etc., and achieve the effects of rich aroma, long appearance, good surface smoothness and low labor cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described in detail below through specific embodiments:

[0038] A bead-shaped black tea processing technology includes the following steps:

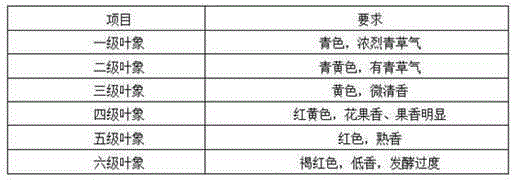

[0039] (1) Withering: spread the tea leaves with one bud and two leaves in the withering trough. The young leaves, rain leaves and dew leaves are spread thinly, and the old leaves are thick. The thickness of the spread leaf is 15-20cm, and the thickness of this embodiment is 18cm. The tea leaves need to be shaken every 1.5h. When shaking, the hand gesture is required to be light, shake loosely, and turn thoroughly to avoid damage to the buds and leaves. The withering time is 7 hours. The tea leaves are blown under the withering trough. The air volume is adjusted appropriately according to the water content of the fresh leaves, the thickness of the leaf layer and the softness of the leaf texture. The standard is not to blow the leaf layer or appear "hollow". The temperature is 30°C, the air humidi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com