Preparation method of montmorillonite-modified crosslinked acrylate-hybridized core-shell emulsion

A technology of acrylate and core-shell emulsion, which is applied in the direction of coating, etc., can solve the problems of poor water resistance, low cost, high temperature back-adhesion and poor heat resistance, and achieve environmental friendliness, good room temperature film-forming performance, and good dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

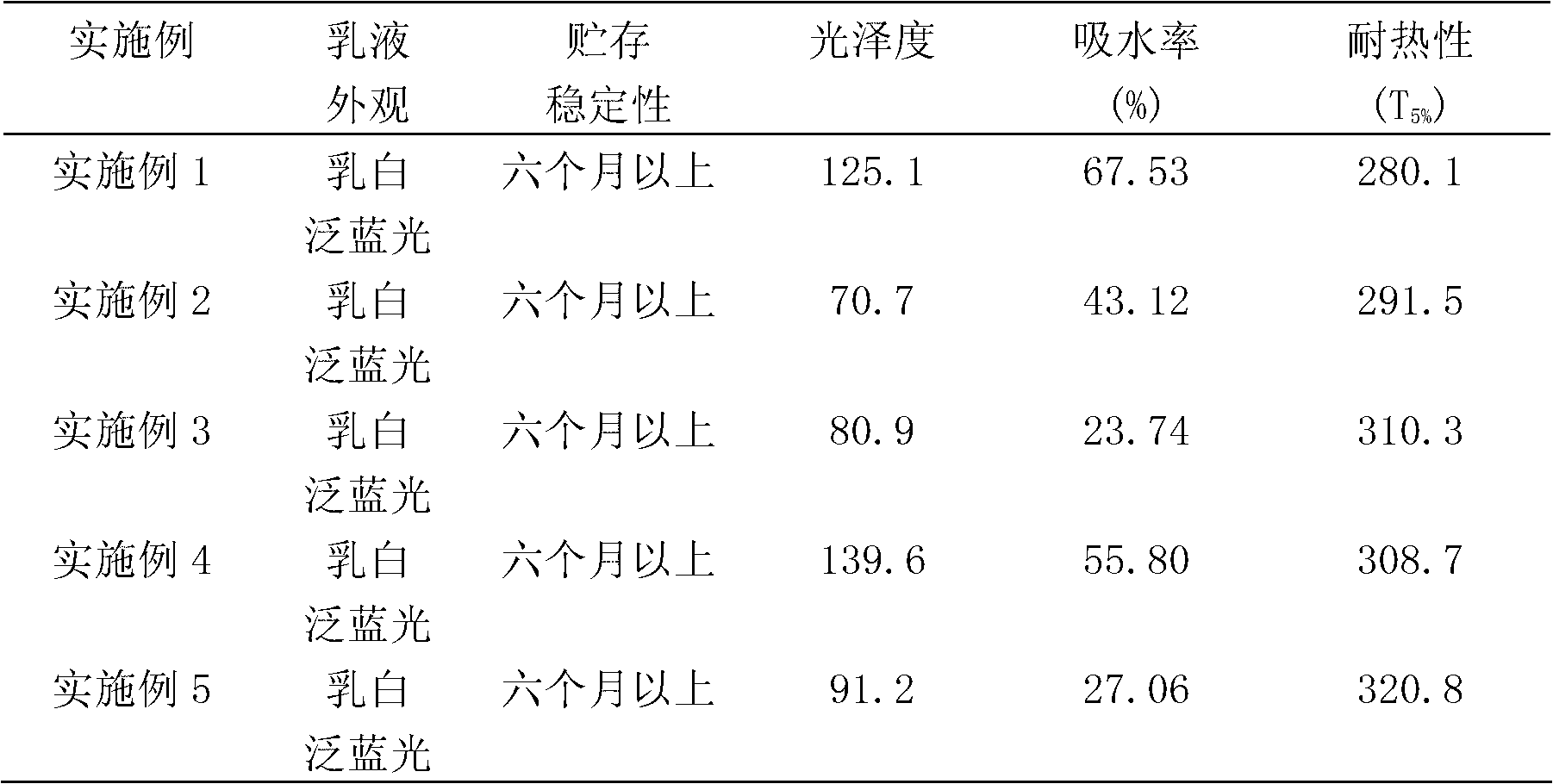

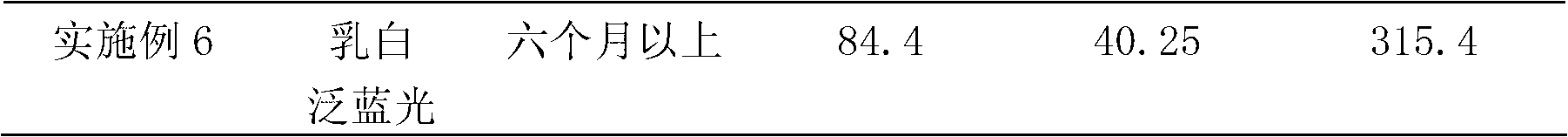

Examples

Embodiment 1

[0051] A montmorillonite modified cross-linked acrylate hybrid core-shell emulsion is prepared by the following method:

[0052] (1) Add 0.3 g of sodium montmorillonite (ion exchange capacity 90 mmol / 100g), 0.45 g of SDS, 0.15 g of OP-10, and 0.2 g of sodium bicarbonate into 40 g of water and stir for 24 hours to obtain a suspension of sodium montmorillonite .

[0053] (2) In a four-necked reaction flask equipped with a reflux condenser, a mechanical stirrer, a nitrogen conduit, and a constant pressure dropping funnel, add the sodium-based montmorillonite suspension and the nuclear monomer mixture (0.7 g Methyl methacrylate + 0.3g butyl acrylate + 0.01g ethylene glycol dimethacrylate), stir evenly, when the temperature rises to 70°C, add 2 grams of potassium persulfate solution (mass fraction 4%), wait until the system appears When light blue, keep warm for half an hour to obtain seed emulsion.

[0054](3) Preparation of nuclear emulsion: Continuously drop the nuclear monome...

Embodiment 2

[0057] A montmorillonite modified cross-linked acrylate hybrid core-shell emulsion, prepared by the following method:

[0058] (1) Add 0.6 g of Na-montmorillonite (ion exchange capacity 90 mmol / 100g), 0.4 g of SDS, 0.2 g of OP-10, and 0.2 g of sodium bicarbonate into 40 g of water and stir for 48 hours to obtain a suspension of Na-montmorillonite .

[0059] (2) In a four-necked reaction flask equipped with a reflux condenser, a mechanical stirrer, a nitrogen conduit, and a constant pressure dropping funnel, add the sodium-based montmorillonite suspension in step (1), and the nuclear monomer mixture (0.7 g Methyl methacrylate + 0.3g butyl acrylate + 0.01g ethylene glycol dimethacrylate), stir evenly, when the temperature rises to 75°C, add 2g of sodium persulfate solution (mass fraction 4%), wait until the system appears When light blue, keep warm for half an hour to obtain seed emulsion.

[0060] (3) Preparation of nuclear emulsion: Continuously drop the nuclear monomer mixt...

Embodiment 3

[0063] A montmorillonite modified cross-linked acrylate hybrid core-shell emulsion, prepared by the following method:

[0064] (1) Add 0.9 g of Na-montmorillonite (ion exchange capacity 90 mmol / 100g), 0.15 g of SDS, 0.45 g of OP-10, and 0.2 g of sodium bicarbonate into 40 g of water and stir for 72 hours to obtain Na-montmorillonite suspension .

[0065] (2) In a four-necked reaction flask equipped with a reflux condenser, a mechanical stirrer, a nitrogen conduit, and a constant pressure dropping funnel, add the sodium-based montmorillonite suspension in step (1), and the nuclear monomer mixture (0.7 g Methyl methacrylate + 0.3g butyl acrylate + 0.01g ethylene glycol dimethacrylate), stir evenly, when the temperature rises to 80°C, add 2g of ammonium persulfate solution (mass fraction 4%), wait until the system appears When light blue, keep warm for half an hour to obtain seed emulsion.

[0066] (3) Preparation of nuclear emulsion: Continuously drop the nuclear monomer mixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com