Preparation method of sheet billet continuous casting and rolling easy-acid washing hot rolling strip steel

A technology of thin slab continuous casting and hot-rolled strip steel, which is applied in metal rolling, metal rolling, tool manufacturing, etc., can solve the problems that the surface of hot-rolled steel plates is difficult to pickle, and achieve reduced oxidation time, improved plasticity, and reasonable The effect of control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

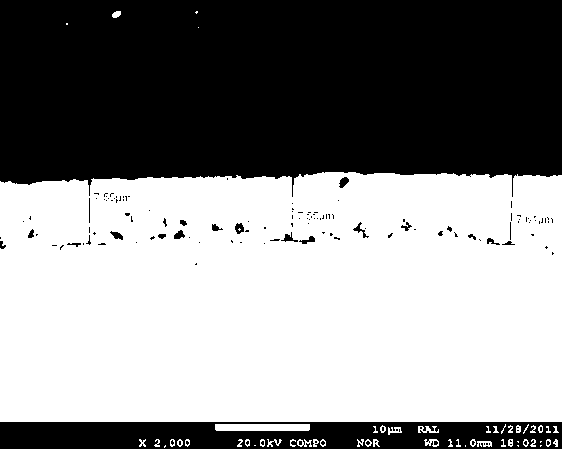

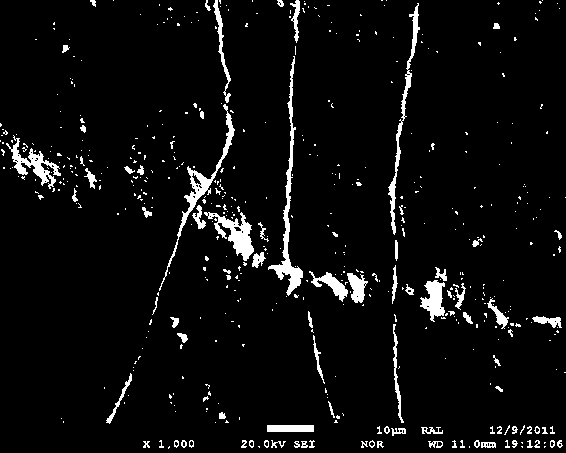

Image

Examples

Embodiment 1

[0031] (1) Smelting molten steel and continuously casting it into slabs, its composition by weight percentage is C: 0.045%, Si: 0.012%, Mn: 0.18%, P: ≤0.02%, S: ≤0.006%, Al: 0.022%, The balance is iron;

[0032] (2) Heating the slab to 1150°C to take it out of the furnace, and descaling the slab with high-pressure water, the descaling water pressure is 30MPa;

[0033] (3) Put the descaled slab into the finish rolling unit, and then carry out finish rolling. The start rolling temperature of finish rolling is 1110°C, the finish rolling temperature is 880°C, and the rolling speed during finish rolling is 8.9m / s. During the finishing rolling process, the cooling water volume between the first and second racks is 60%, the cooling water volume between the second and third racks is 50%, and the cooling water volume between the third and fourth racks is 40%. %, the cooling water volume between the fourth and fifth racks is 35%, the cooling water volume between the fifth and sixth rac...

Embodiment 2

[0036](1) Smelting molten steel and continuously casting it into slabs, its composition by weight percentage is C: 0.034%, Si: 0.015%, Mn: 0.16%, P: ≤0.02%, S: ≤0.006%, Al: 0.032%, The balance is iron;

[0037] (2) Heat the slab to 1120°C and take it out of the furnace, and descale the slab with high-pressure water, and the descaling water pressure is 32MPa;

[0038] (3) Put the descaled slab into the finish rolling unit, and then carry out finish rolling. The start temperature of finish rolling is 1080°C, the finish rolling temperature is 860°C, and the rolling speed during finish rolling is 9.2m / s. During the finishing rolling process, the cooling water volume between the first and second racks is 70%, the cooling water volume between the second and third racks is 55%, and the cooling water volume between the third and fourth racks is 45%. %, the cooling water volume between the fourth and fifth racks is 30%, the cooling water volume between the fifth and sixth racks is 20%...

Embodiment 3

[0041] (1) Smelting molten steel and continuously casting it into slabs, its composition by weight percentage is C 0.1%, Si 0.2%, Mn 0.05%, P ≤ 0.02%, S ≤ 0.01%, Al 0.01%, and the balance is iron ;

[0042] (2) Heat the slab to 1100°C to leave the heating furnace, and descale the slab with high-pressure water, and the water pressure during descaling is 28MPa;

[0043] (3) Put the descaled slab into the finish rolling unit, and then carry out finish rolling. The start temperature of finish rolling is 1050°C, the finish rolling temperature is 920°C, and the rolling speed during finish rolling is 5m / s. During the rolling process, the cooling water volume between the first and second racks is 70%, the cooling water volume between the second and third racks is 60%, and the cooling water volume between the third and fourth, fourth and fifth racks The cooling water volume of the rack is 30%, and the cooling water volume between the fifth and sixth, sixth and seventh racks is 15% res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com