Silicon-containing lithium cathode, preparation method thereof and lithium sulfur battery with silicon-containing lithium cathode

A technology of lithium negative electrode and silicon negative electrode, which is applied in the field of chemical power sources, can solve the problems of not being able to provide lithium ions for lithium-sulfur batteries, and achieve the effects of improving battery cycle performance and safety performance, wide adjustable range, and reducing the amount of lithium metal used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

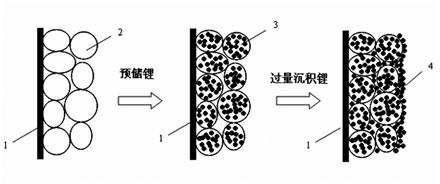

Method used

Image

Examples

Embodiment 1

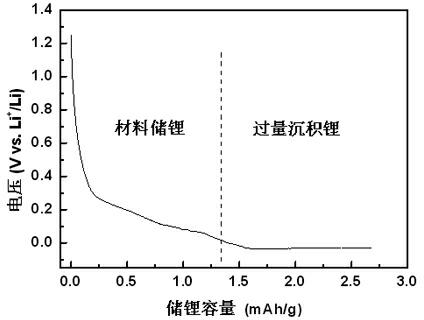

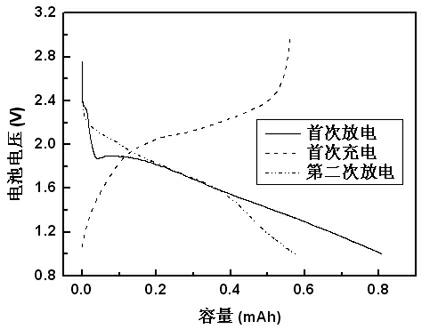

[0022] Preparation of negative electrode sheet: Silicon / carbon composite material is used as the negative electrode material, mixed with conductive carbon black (Super P), sodium carboxymethyl cellulose (CMC), and styrene-butadiene rubber (SBR) in a mass ratio of 80:8:4:8 , using deionized water as a solvent, mixed to form a slurry, evenly coated on the current collector Cu foil, and then dried in a vacuum oven at 80 ° C for 24 hours. With metal lithium as the negative electrode, mesophase carbon microspheres as the positive electrode, Celgrad 2035 as the diaphragm, 1.5mol / L lithium hexafluorophosphate (LiPF 6 ) / Ethylene Carbonate (EC) + Diethyl Carbonate (DEC) + Ethyl Methyl Carbonate (EMC) (volume ratio 1:1:1) as the electrolyte to assemble the battery. The battery is first discharged-charged at a current density of 50mA / g active material, and the voltage range is 0.01-2V. After 8 cycles, the capacity of the silicon material reaches a stable level. The 9th lap continues to ...

Embodiment 2

[0024] Preparation of negative electrode sheet: Silicon / carbon composite material is used as the negative electrode material, mixed with conductive carbon black (Super P), sodium carboxymethyl cellulose (CMC), and styrene-butadiene rubber (SBR) in a mass ratio of 80:8:4:8 , using deionized water as a solvent, mixed to form a slurry, evenly coated on the current collector Cu foil, and then dried in a vacuum oven at 80 ° C for 24 hours. With metal lithium as the negative electrode, mesophase carbon microspheres as the positive electrode, Celgrad 2035 as the diaphragm, 1.5mol / L lithium hexafluorophosphate (LiPF 6 ) / Ethylene Carbonate (EC) + Diethyl Carbonate (DEC) + Ethyl Methyl Carbonate (EMC) (volume ratio 1:1:1) as the electrolyte to assemble the battery. The battery is first discharged-charged at a current density of 50mA / g active material, and the voltage range is 0.01~2V. After 8 cycles, the capacity of the silicon material is stable, and the stable lithium storage capacity...

Embodiment 3

[0026] Preparation of negative electrode sheet: Silicon / carbon composite material is used as the negative electrode material, mixed with conductive carbon black (Super P), sodium carboxymethyl cellulose (CMC), and styrene-butadiene rubber (SBR) in a mass ratio of 80:8:4:8 , using deionized water as a solvent, mixed to form a slurry, evenly coated on the current collector Cu foil, and then dried in a vacuum oven at 80 ° C for 24 hours. With lithium metal as the negative electrode, mesophase carbon microspheres as the positive electrode, Celgrad 2035 as the separator, 1.5mol / L lithium bis(trifluoromethylsulfonyl)imide (LiTFSI) / dioxolane (DOL)+1, 2-Dimethoxyethane (DME) (volume ratio 1:1) is used as the electrolyte to assemble the battery. The battery is first discharged-charged at a current density of 50mA / g active material, and the voltage range is 0.01~2V. After 8 cycles, the capacity of the silicon material is stable, and the stable lithium storage capacity of the 8th cycle i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com