Preparation method of thermosetting acrylic resin binder

A technology of acrylic resin and binder, applied in the direction of adhesive, binder type, graft polymer binder, etc., can solve the problems of glass wool application field limitation and limited glass wool application scope.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

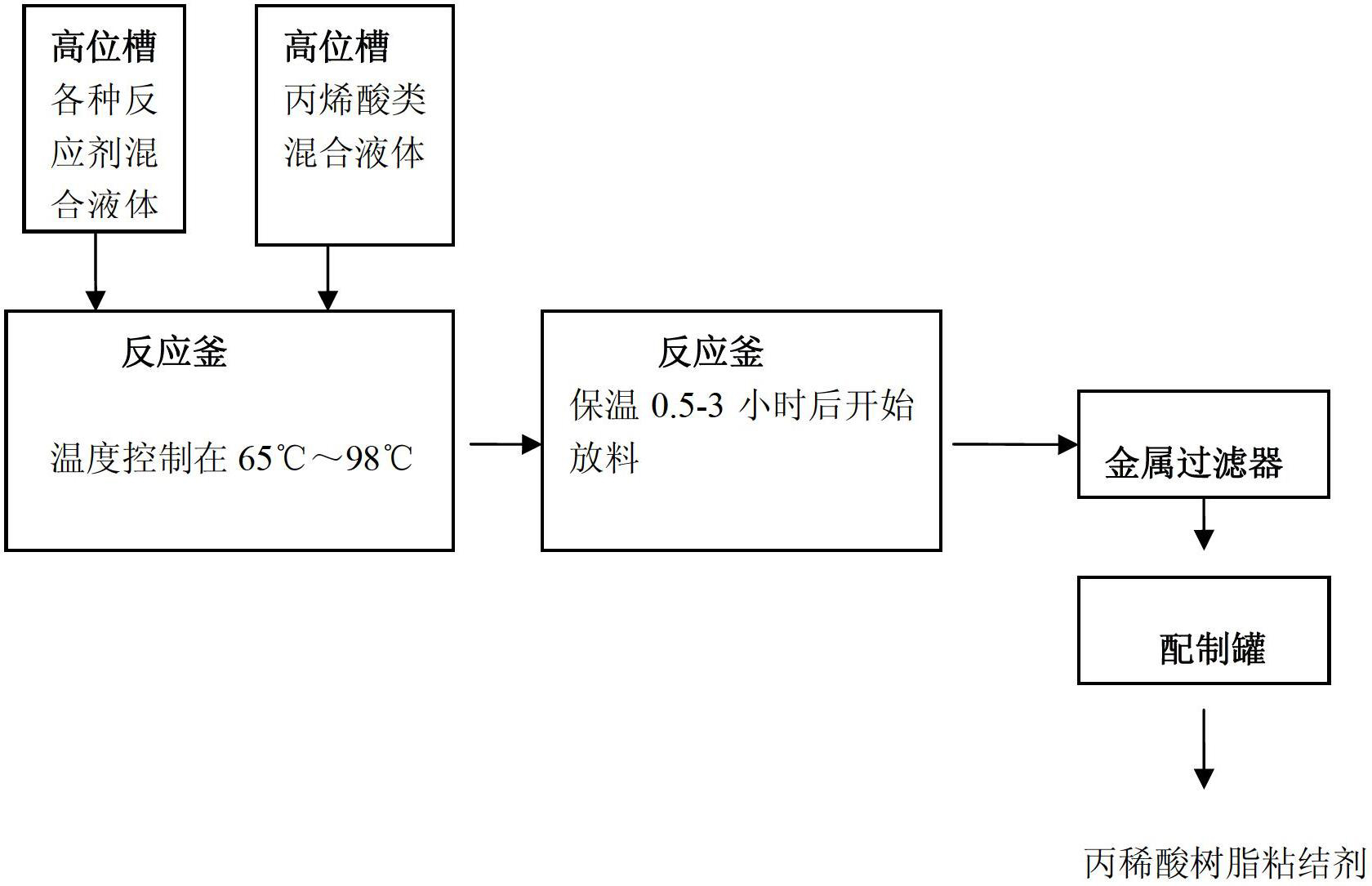

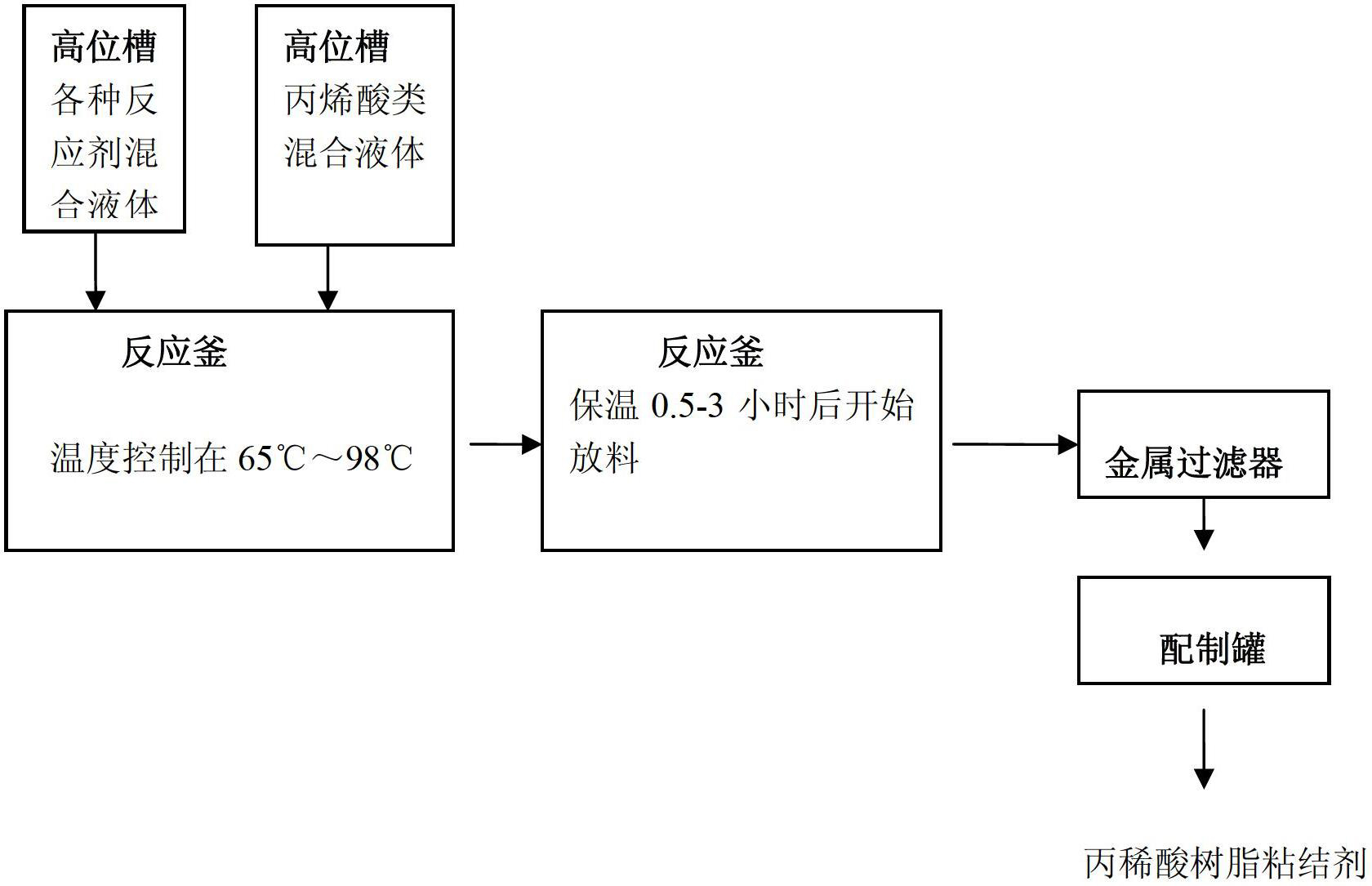

Method used

Image

Examples

Embodiment 1

[0035] The raw materials are: 16kg of acrylic acid, 30kg of methyl acrylate, 0.5kg of isopropanol, 1.0kg of sodium hypophosphite, 3.5kg of hydrogen peroxide, 0.8kg of sodium lauryl sulfate, 1.5kg of KH570, 0.5 kg of methyl silicone oil kg, Kaison CG0.3kg, deionized water 80kg.

[0036] First add 0.5kg of sodium hypophosphite and 0.5kg of isopropanol, add 2.0kg of deionized water, then use a vacuum pump to pump into the reaction kettle, add 70kg of deionized water, and start to heat up.

[0037] Then pump 16kg of acrylic acid and 30kg of methyl acrylate into the elevated tank and stir for 10-90 minutes, and set aside;

[0038] After dissolving 3.5kg of hydrogen peroxide, 0.8kg of sodium lauryl sulfate, 0.5kg of methyl silicone oil, 0.3kg of Kayson CG and 10kg of deionized water, it is pumped into another elevated tank for use.

[0039] When the temperature of the reaction kettle rises to 50-95°C, start to add the mixed solution of acrylic monomer and polyester intermediate of ...

Embodiment 2

[0045] The raw materials are: 26kg of acrylic acid, 20kg of hydroxyethyl acrylate, 1.0kg of isopropanol, 1.0kg of potassium persulfate, 1.0kg of sodium lauryl sulfate, 1.5kg of KH560, 0.5kg of silicone oil, 1,2 benzoiso Thiazolone-3-one 0.2kg, deionized water 80KG.

[0046] First add 1.0kg of isopropanol and 2.0KG of deionized water, then pump it into the reactor with a vacuum pump, then add 70kg of deionized water, turn on the mixer of the reactor, and start to heat up.

[0047] Then pump 26kg of acrylic acid and 20kg of hydroxyethyl acrylate into the head tank and stir for 10-90 minutes, then set aside;

[0048] After dissolving 1.0kg of potassium persulfate, 1.0kg of sodium lauryl sulfate, 0.5kg of hydroxyl silicone oil, 0.2kg of 1,2 benzisothiazolinone-3-one and 10kg of deionized water, pump it into Another high level slot is ready for use.

[0049] When the temperature of the reaction kettle rises to 50-90°C, start to add the mixed solution of acrylic monomer and polyes...

Embodiment 3

[0055] The raw materials are: 28kg of polyacrylic acid, 16kg of propyl acrylate, 0.5kg of isopropanol, 1.0kg of sodium hypophosphite, 0.7KG of sodium persulfate, 0.8kg of sodium dodecyl sulfate, 1.5kg of KH550, 0.5 hydroxy silicone oil KG, Kaisong CG 0.3kg, deionized water 91kg.

[0056] First add 2.0kg of sodium hypophosphite, 0.5kg of isopropanol, and 2.0kg of deionized water, then pump them into the reaction kettle with a vacuum pump, then add 75kg of deionized water, and start to heat up.

[0057] Then pump 28kg of polyacrylic acid and 14kg of propyl acrylate into the elevated tank and stir for 10-60 minutes, then set aside;

[0058] After dissolving 0.7kg of sodium persulfate, 0.8kg of sodium lauryl sulfate, 0.5kg of hydroxyl silicone oil, 0.3kg of Kayson CG and 16kg of deionized water, pump it into another elevated tank for use.

[0059] When the temperature of the reaction kettle rises to 50-90°C, start to add the mixed solution of acrylic monomer and polyester interme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com