Luminescent glass and microcrystalline glass and preparation method thereof

A technology of glass-ceramics and luminescent glass, which is applied in the field of lighting engineering, can solve problems such as low light intensity and unstable physical and chemical properties, and achieve the effects of high solubility, favorable rare earth luminescence, and low phonon energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Rare earth doped SrO-TiO 2 -SiO 2 A method for preparing a system luminescent glass, comprising the steps of:

[0044] The selection of raw materials, according to the molar percentage of each component SrO: 30%, TiO 2 : 15%, SiO 2 : 40%, CaF 2 : 15%, Sm 2 o 3 : 0.5% weighed raw materials, set aside, of which, Sm 2 o 3 Introduced by means of addition;

[0045] SrO, TiO 2 , SiO 2 , CaF 2 and Sm 2 o 3 The raw materials were fully ground in the agate grinding machine, mixed evenly, poured into a platinum crucible, covered with a crucible lid, and put into a high-temperature furnace for melting at a melting temperature of 1430°C and kept for 2 hours to obtain molten glass;

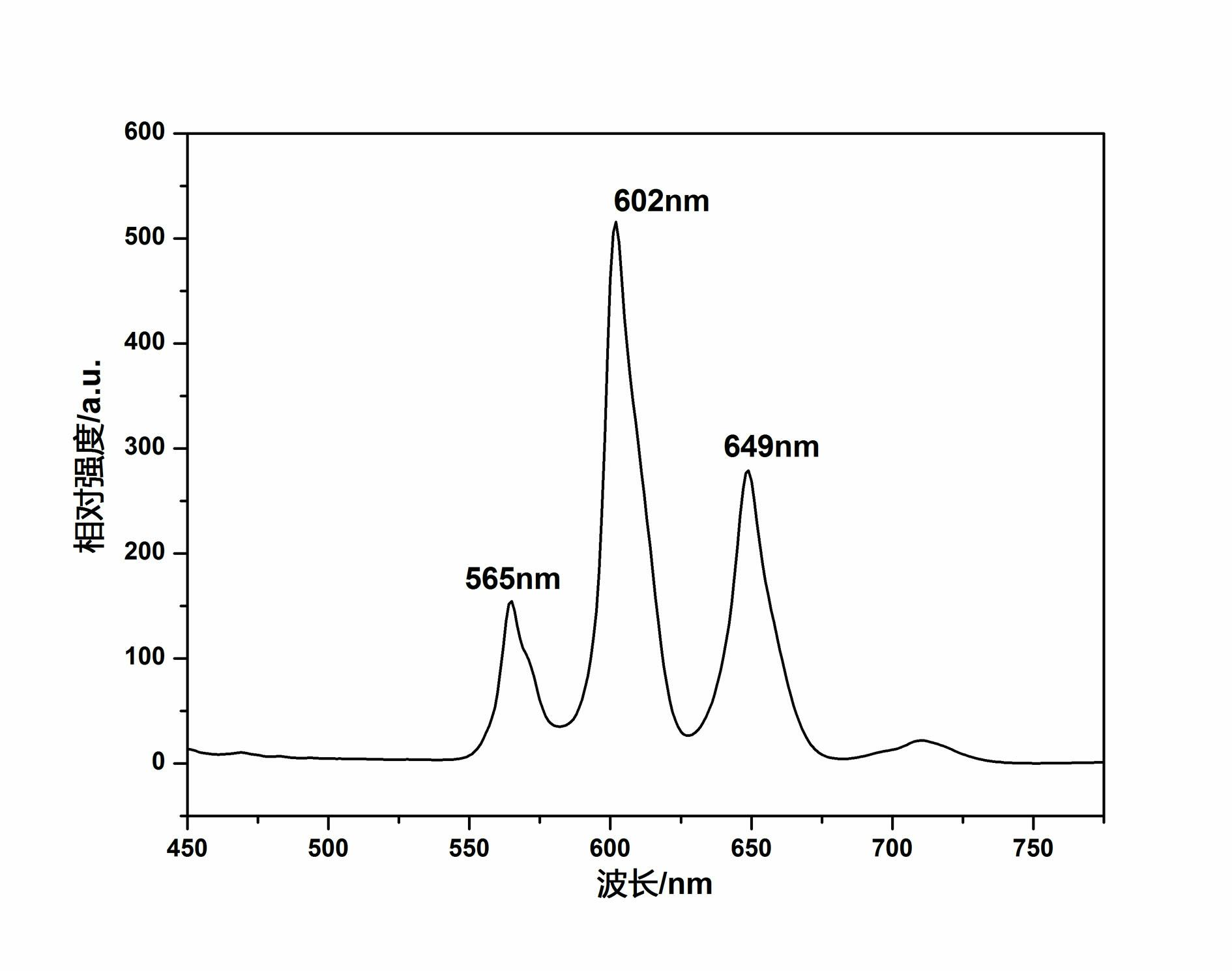

[0046] The molten glass was poured into a heat-resistant mold preheated at 400 °C for 50 min to form it, then placed in a muffle furnace for annealing at 700 °C for 1 h, and cooled to room temperature with the furnace to obtain Sm 3+ doped SrO-TiO 2 -SiO 2 System luminous glass.

[0047...

Embodiment 2

[0049] Rare earth doped SrO-TiO 2 -SiO 2 A method for preparing a system luminescent glass, comprising the steps of:

[0050] The selection of raw materials, according to the molar percentage of each component SrO: 30%, TiO 2 : 15%, SiO 2 : 50%, SrF 2 : 5%, Tb 4 o 7 : 0.5% weighed raw materials, set aside, of which, Tb 4 o 7 Introduced by means of addition;

[0051] SrO, TiO 2 , SiO 2 , SrF 2 and Tb 4 o 7 The raw materials were fully ground in the agate grinding machine, mixed evenly, poured into a platinum crucible, covered with a crucible lid, and melted in a high-temperature furnace at a melting temperature of 1490 °C for 1.5 h to obtain molten glass;

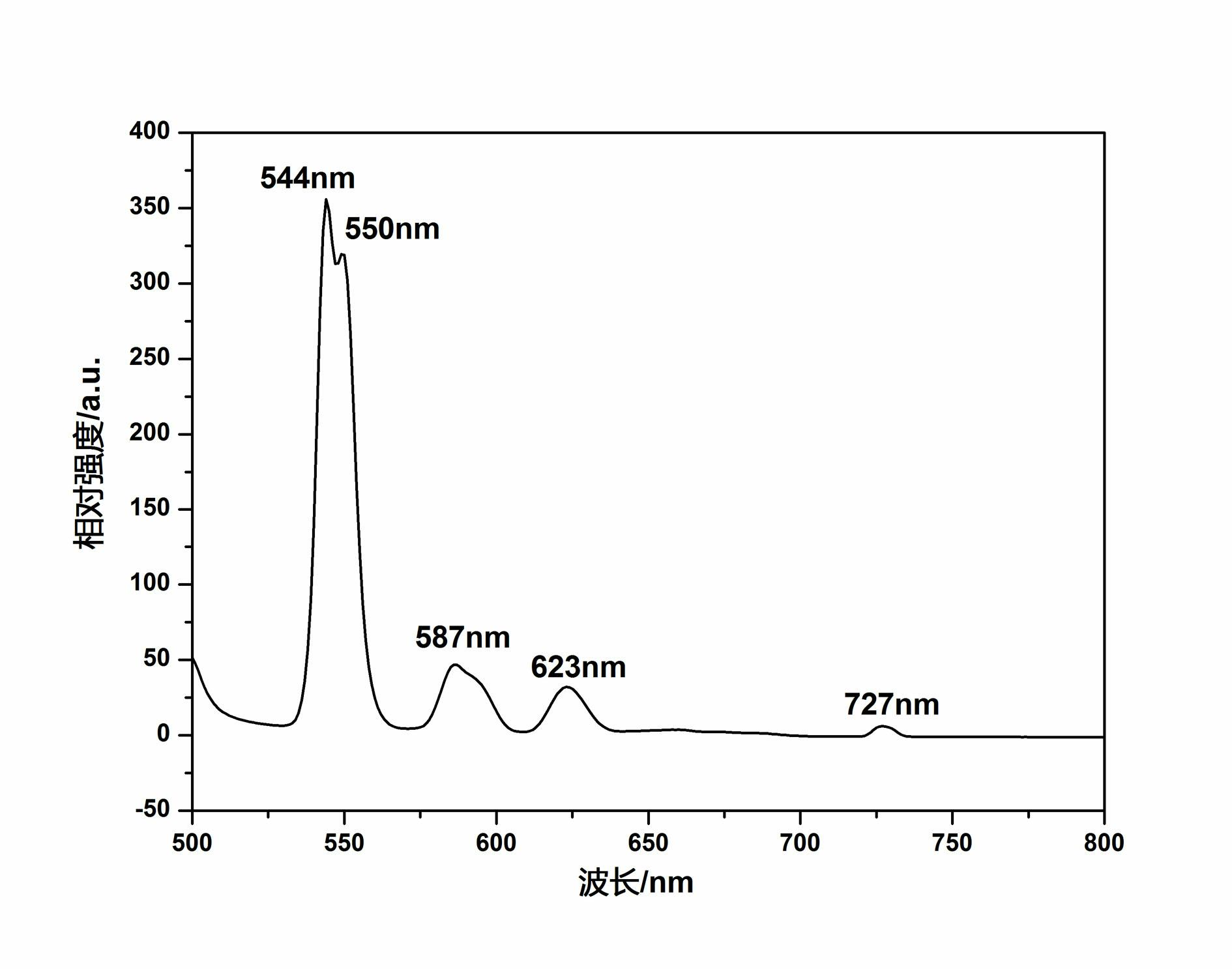

[0052] The molten glass was poured into a heat-resistant mold preheated at 550 °C for 30 min to form it, then placed in a muffle furnace for annealing at 680 °C for 1.5 h, and cooled to room temperature with the furnace to obtain Tb 3+ doped SrO-TiO 2 -SiO 2 System luminous glass.

[0053] With embodiment 2 ...

Embodiment 3

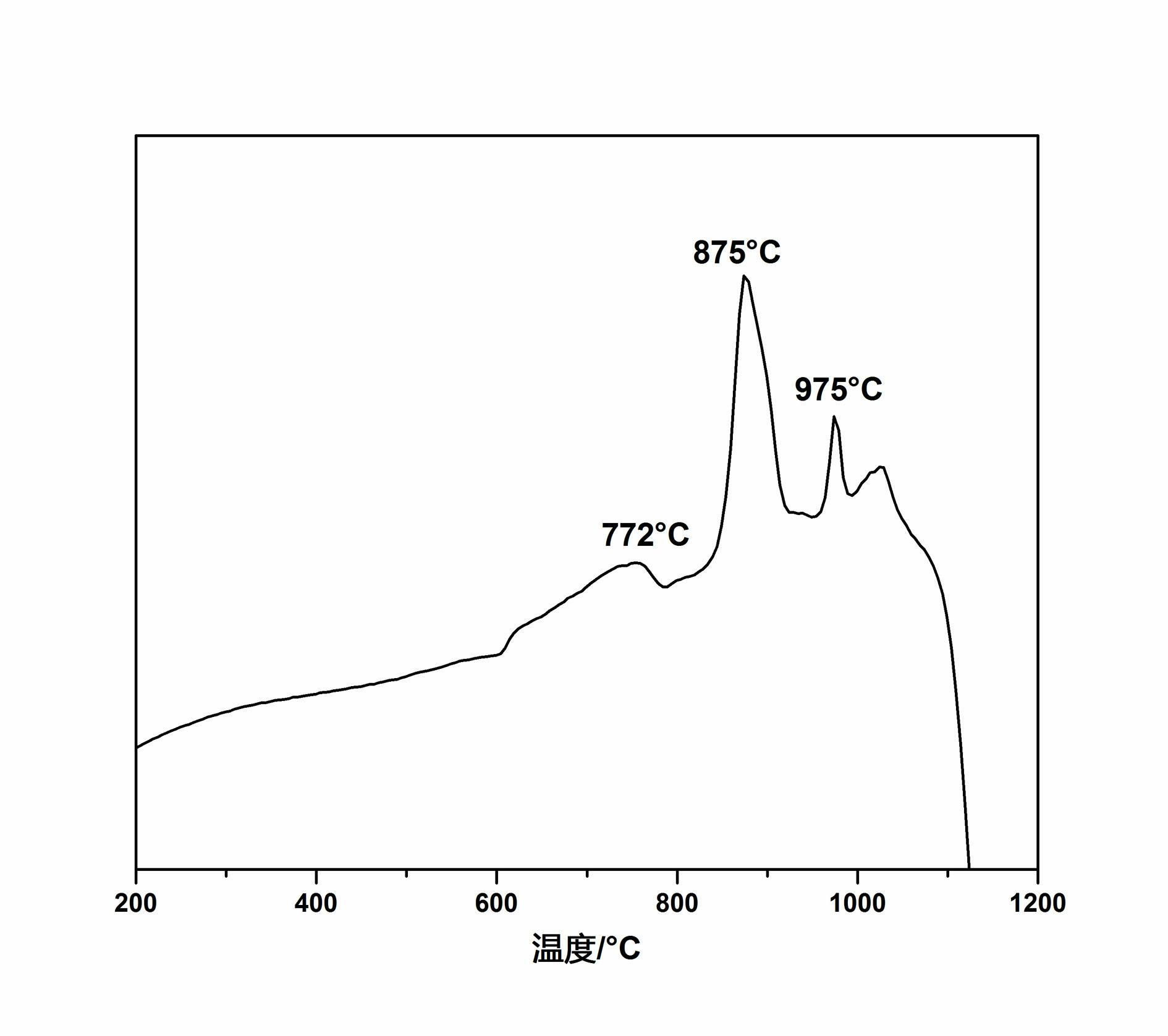

[0055] Rare earth doped SrO-TiO 2 -SiO 2 The preparation method of the transparent luminescent glass-ceramics of the system comprises the following steps:

[0056] The selection of raw materials, according to the mole percentage of each component is: SrO: 26%, TiO 2 : 16%, SiO 2 : 45%, SrF 2 : 13%, Sm 2 o 3 : 0.25%, Tb 4 o 7 : 0.625%, weigh raw materials, set aside, of which, Sm 2 o 3 , Tb 4 o 7 Introduced by means of addition;

[0057] SrO, TiO 2 , SiO 2 , SrF 2 、Sm 2 o 3 and Tb 4 o 7 The raw materials were fully ground in the agate grinding machine, mixed evenly, poured into a platinum crucible, covered with a crucible lid, and melted in a high-temperature furnace at a melting temperature of 1480 °C for 1.5 h to obtain molten glass;

[0058] The molten glass was poured into a heat-resistant mold preheated at 500 °C for 40 min to form it, then placed in a muffle furnace for annealing at 680 °C for 1.5 h, and cooled to room temperature with the furnace;

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com