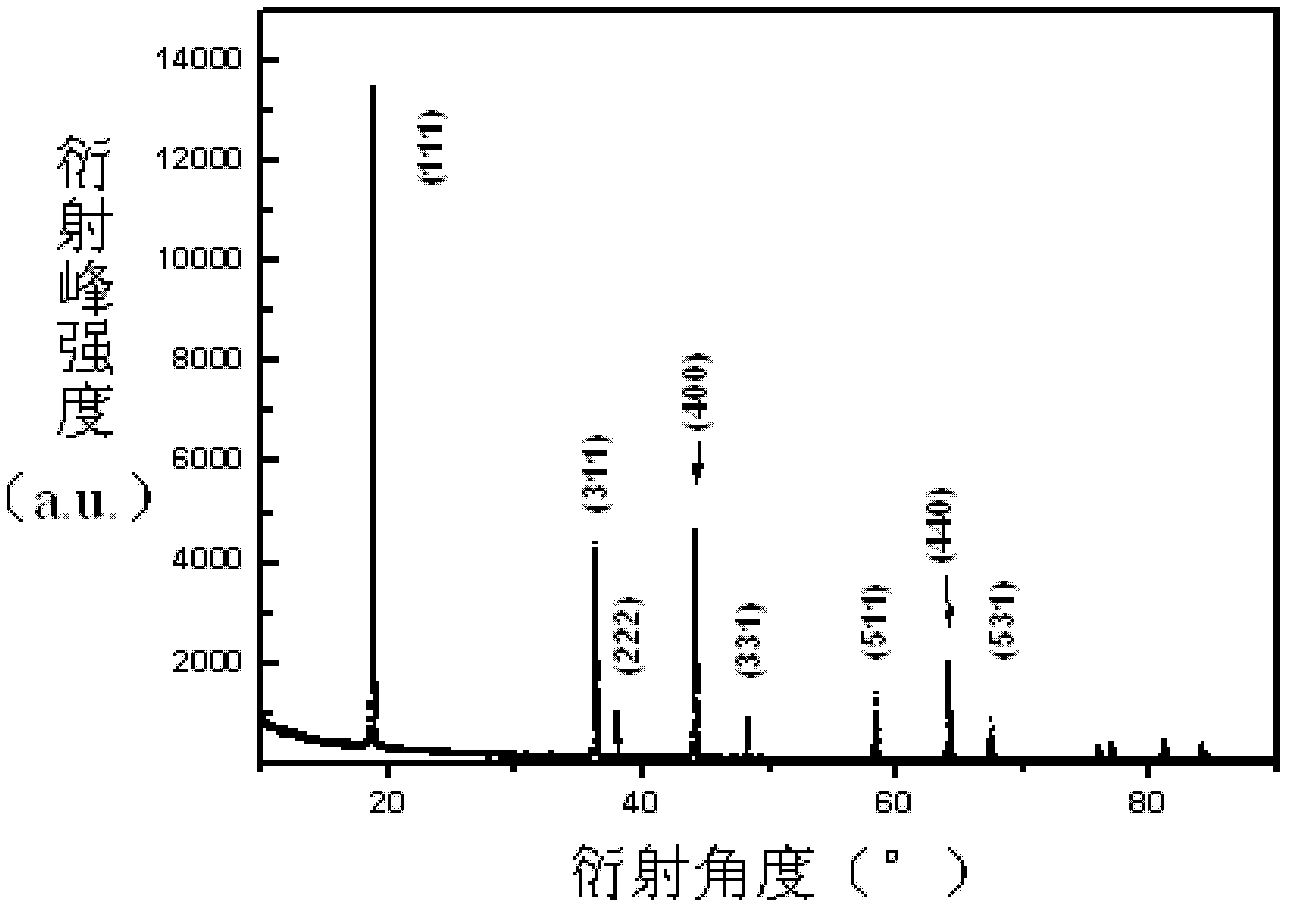

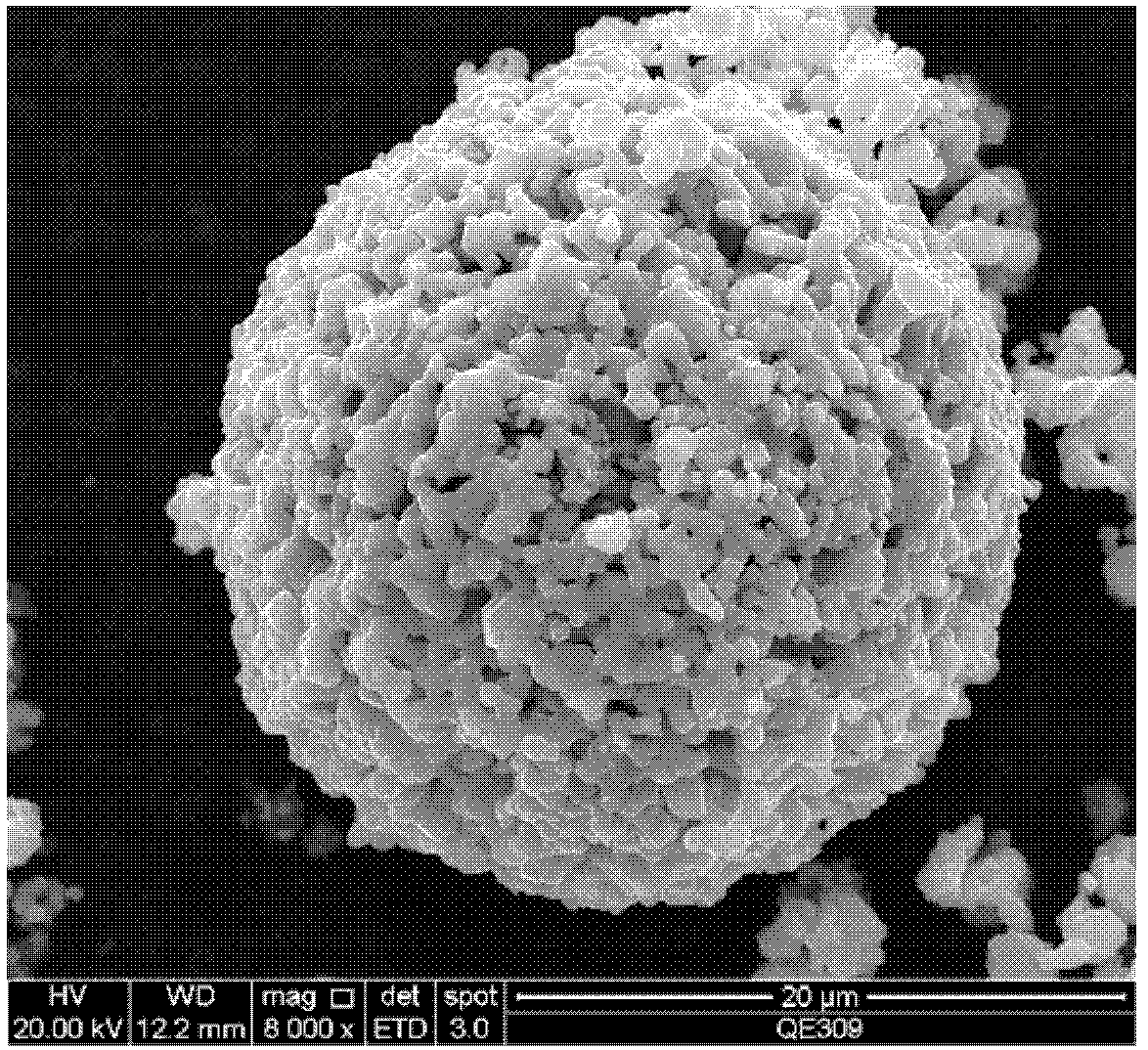

Lithium-manganese-aluminum oxygen anode material and preparation method thereof

A lithium manganese aluminum oxide cathode and cathode material technology, applied in battery electrodes, electrical components, circuits, etc., can solve problems such as lattice defects, poor rate performance of lithium manganate materials, and inability to effectively block corrosion, so as to avoid crystal lattice defects. The formation of lattice defects, the improvement of high temperature cycle performance, and the effect of improving rate performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Correspondingly, the present invention also provides a preparation method of lithium manganese aluminum oxygen cathode material, comprising the following steps:

[0041] Mix manganese source compound, M source compound with the first solvent to obtain the first solution or suspension, M is Li, Mg, Ti, V, Cr, Fe, Mn, Co, Ni, Cu, Zn, Zr , one or more of Nb, Pd, Ce, Nd and Dy;

[0042] mixing the aluminum source compound with a second solvent to obtain a second solution or a second suspension;

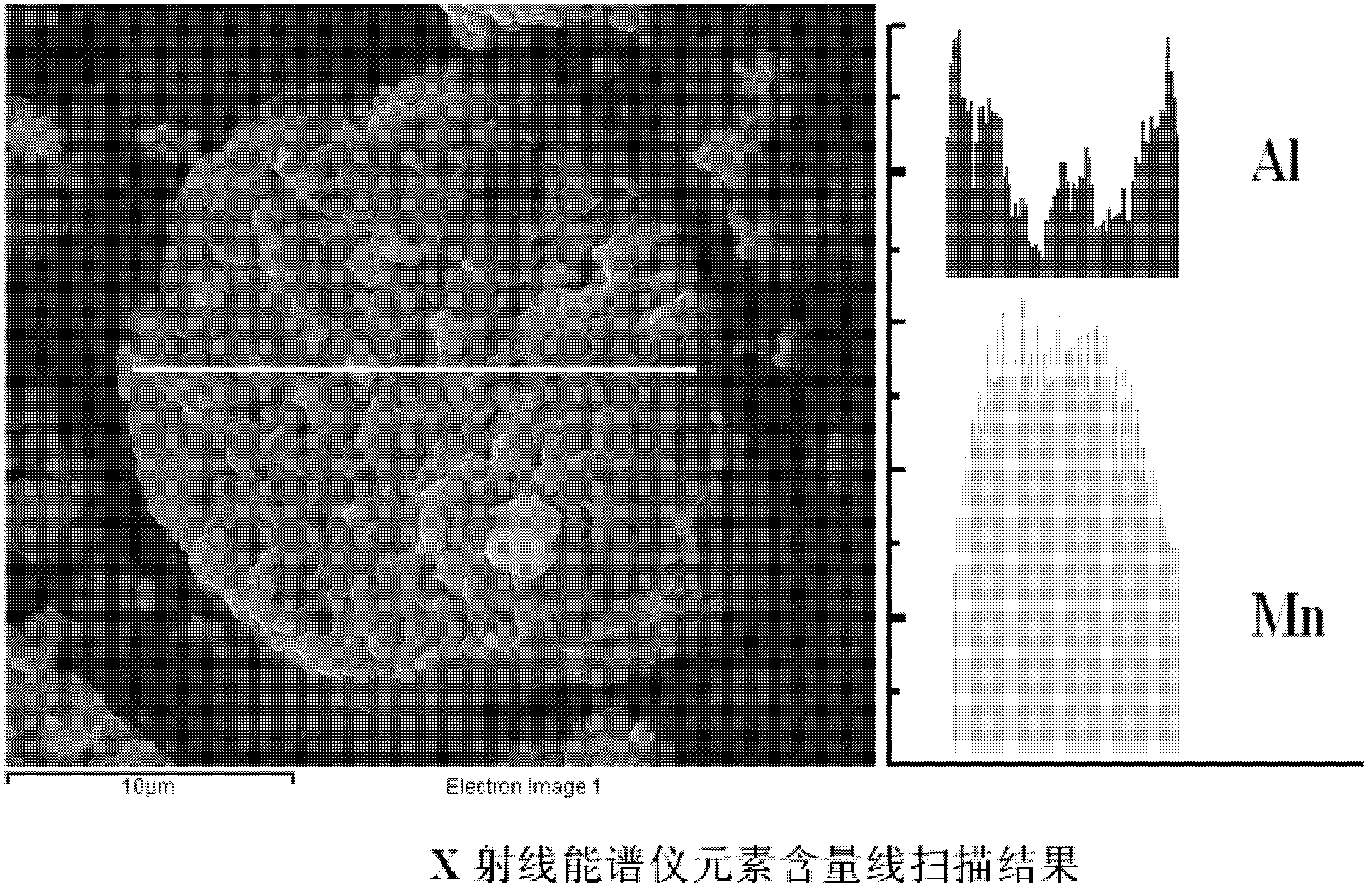

[0043] Add a precipitating agent to the first solution or the first suspension for precipitation, add the second solution or the second suspension during the precipitation process, and gradually increase the amount of the second solution or the second suspension After stirring, a precipitate with a gradient distribution of aluminum elements is formed, and a precursor is obtained after drying, and the precipitating agent is an alkali metal hydroxide solution, an alkali metal carbon...

Embodiment 1~10

[0061] According to the raw materials, dosage and conditions shown in Table 1, the lithium manganese aluminum oxide cathode material precursor with gradient structure was prepared according to the following steps:

[0062] Manganese source compound, M source compound and the first solvent are mixed to obtain the first solution or the first suspension; the aluminum source compound is mixed with the second solvent to obtain the second solution or the second suspension; Add a precipitant to the first solution or the first suspension, add the second solution or the second suspension during the precipitation process, gradually increase the amount of the second solution or the second suspension, and form a gradient distribution of aluminum after stirring Elemental precipitates; drying or roasting the obtained precipitates to obtain precursors.

[0063] Table 1 The formula and conditions for preparing the lithium manganese aluminum oxygen precursor with gradient structure in Examples...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com