Heating furnace with double furnace bodies

A heating furnace and double furnace technology, applied in the field of furnaces and kilns, can solve problems such as uneven heating temperature, and achieve the effects of uniform hot air flow paths, high thermal efficiency, and uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

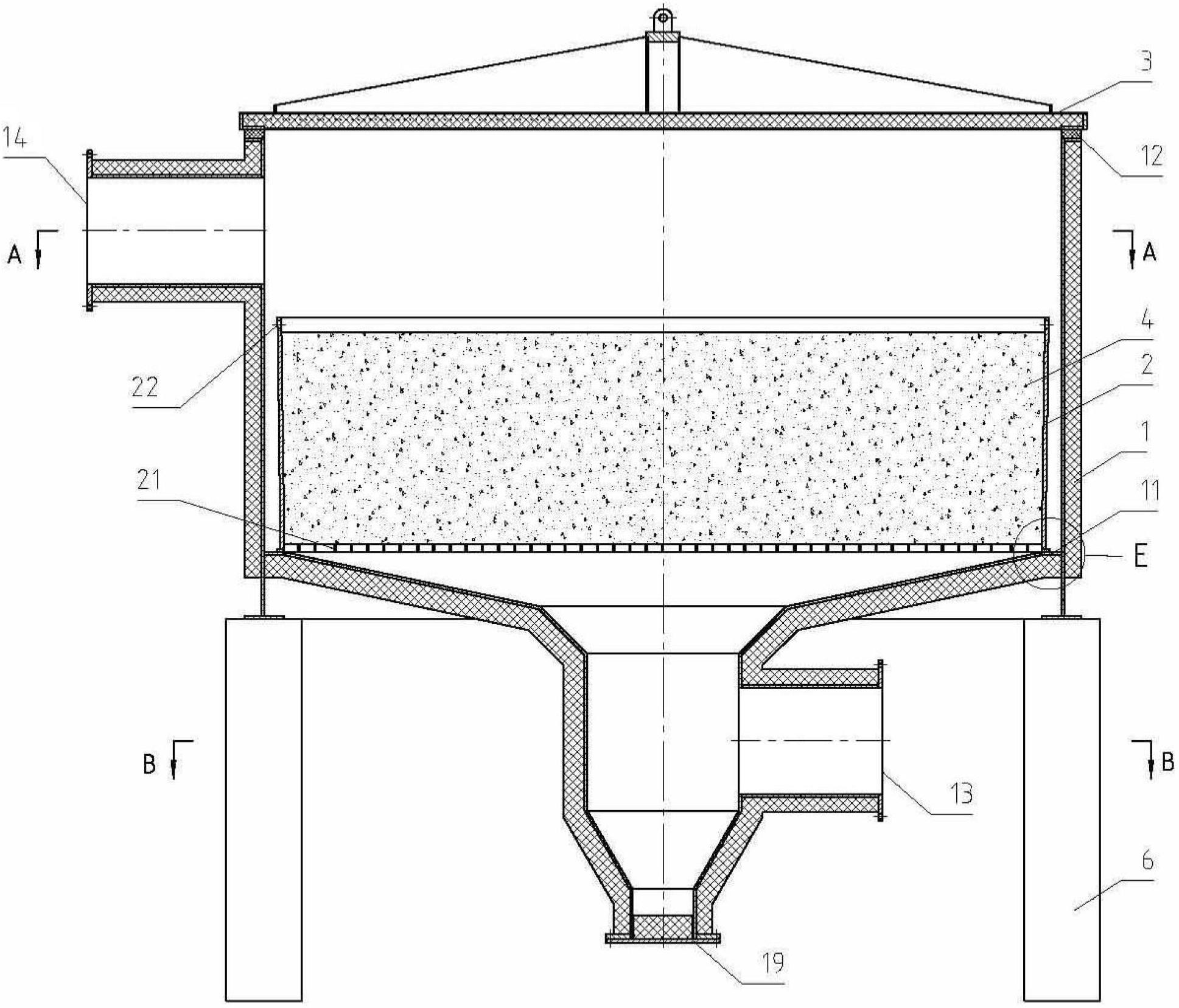

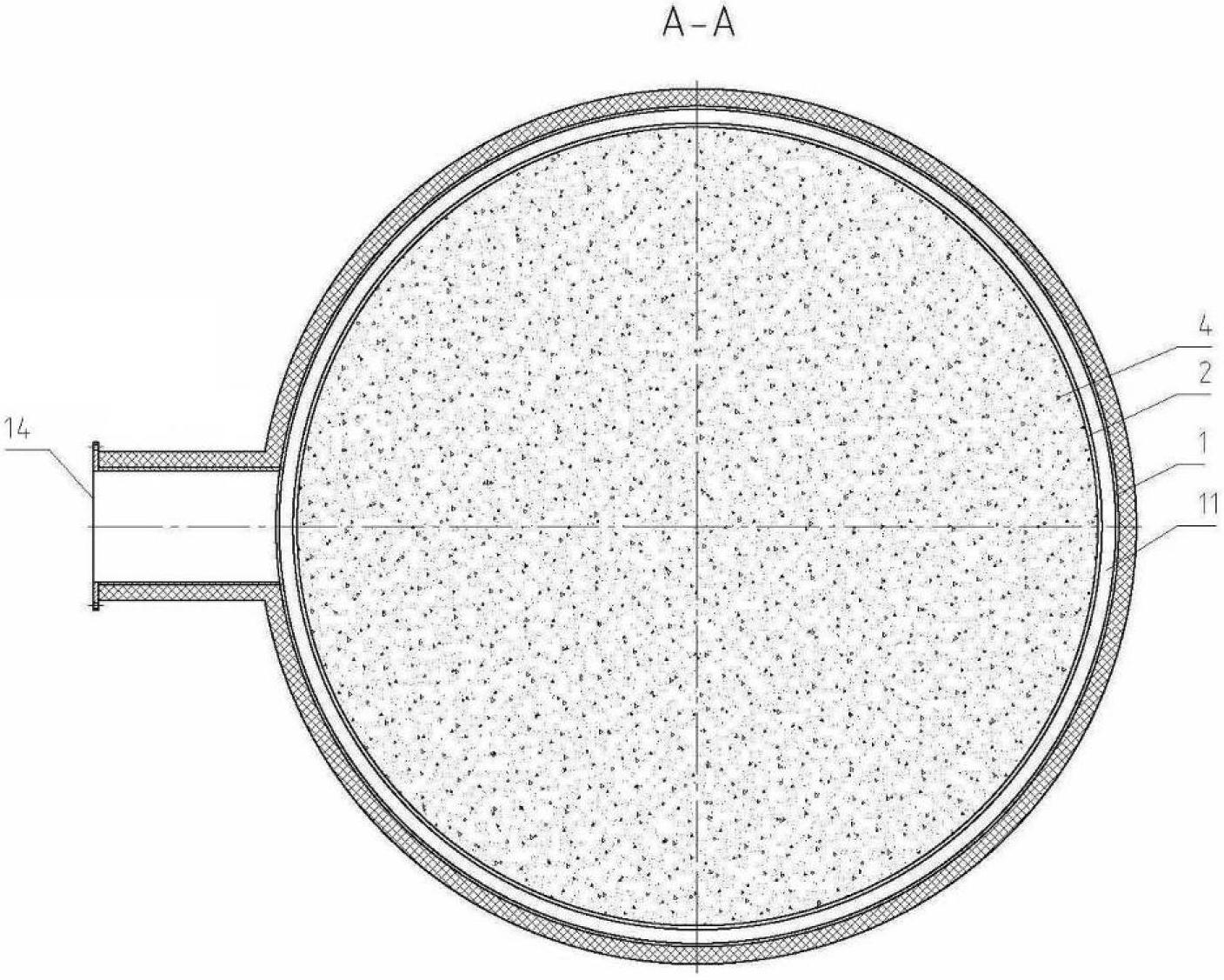

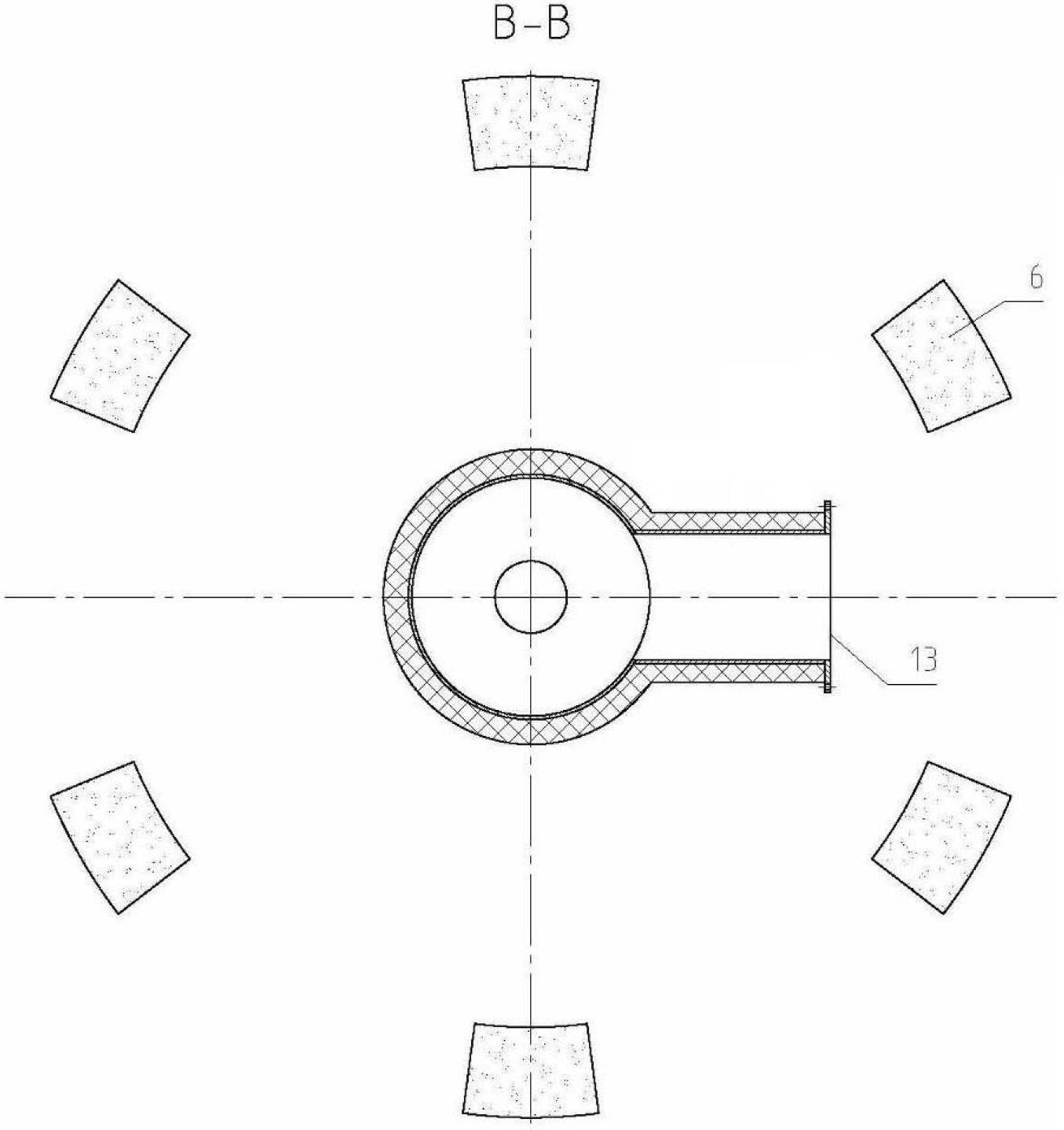

[0032] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 9 Shown, double furnace body heating furnace, it comprises outer furnace body 1, interior furnace body 2, furnace cover 3. The outer furnace body 1 is a circular steel container with a thermal insulation layer on the inner surface to reduce heat loss and reduce heating energy consumption. There is an annular bearing platform 11 inside, and an annular sealing ring 12 is arranged on the upper part. The lower side of the platform 11 is provided with a ventilation hole (air inlet) 13, and the upper side of the platform 11 is provided with a ventilation hole (air outlet) 14; the bottom of the inner furnace body 2 is provided with a grate plate 21 made of heat-resistant steel, The upper part is provided with two hoisting holes 22, and the ferroalloy material 4 is filled inside. The inner furnace body 2 sits on the bearing platform 11 in the outer furnace body 1, and the contact surface between the inner furna...

Embodiment 2

[0036] refer to Figure 5 , Figure 6 , Figure 7 As shown, the furnace cover 3 of the double furnace body heating furnace is provided with a flow equalizing ring 31, and the flow sharing ring 31 is composed of a cylindrical part arranged eccentrically with the center of the furnace cover and a baffle 311 arranged concentrically with the center of the furnace cover. , A crescent-shaped channel is formed between the furnace covers, and the flow rate of the collected airflow is uniform, so that the airflow flowing through the ferroalloy material 4 of the inner furnace body is more uniform; the outer furnace body 1 is provided with an annular groove 17, and the sealing ring 12 is arranged in the annular groove 17 Inside, during the production process, the annular groove 17 is filled with water, and the sealing ring 12 has a longer life under the protection of water; the outer furnace body 1 is provided with a guide rod 18 for positioning the inner furnace body when the inner furna...

Embodiment 3

[0038] refer to Figure 8 , Figure 10 , Figure 11 , Figure 12 , Figure 13 As shown, the double furnace body heating furnace is provided with a furnace cover opening and closing device 5, and the furnace cover 3 is connected with the furnace cover opening and closing device 5, and can be opened or covered by the furnace cover opening and closing device 5. The opening and closing device of the furnace cover includes a lever hinged with the furnace cover, a lever support, a hydraulic cylinder for driving the lever, etc. Figure 10 Among them, S1 is the double furnace body heating furnace (1S1 is the No. 1 furnace, 2S1 is the No. 2 furnace, 3S1 is the No. 3 furnace), S2 is the flue gas furnace, S3 is the combustion-supporting fan, S4 is the gas pipeline, S5 is the chimney, S6 There are 9 valves in total, Figure 11 , Figure 12 , Figure 13 Among them, S7 is the "open state" of the valve S6, and S8 is the "closed state" of the valve S6. All the other are with embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com