Aromatic polyamide/aromatic polyimide blended fiber and preparation method thereof

A technology of aromatic polyamide and polyimide, which is applied in the direction of stretch spinning, conjugated synthetic polymer rayon, chemical post-treatment of synthetic polymer rayon, etc., and can solve the decline in the comprehensive performance of the blend , Failure to improve performance, low mechanical properties of copolymers, etc., to achieve the effects of ensuring compatibility, improving tensile strength, and improving UV resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

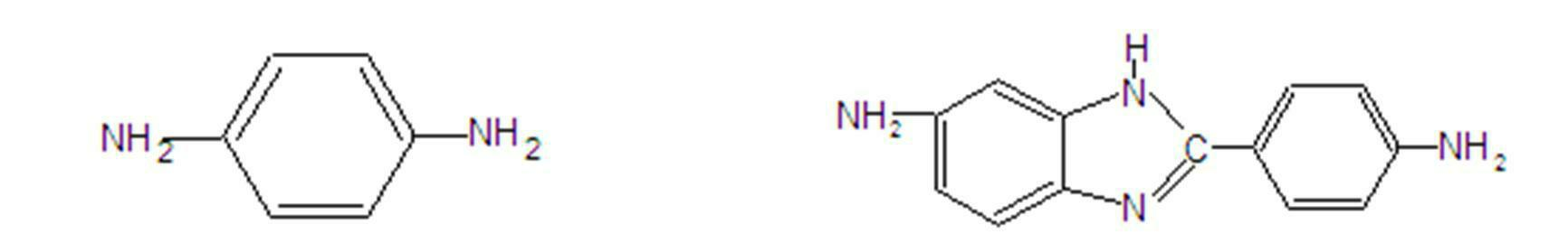

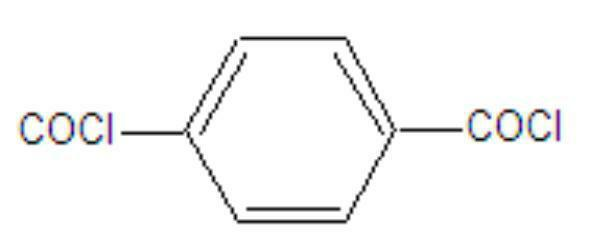

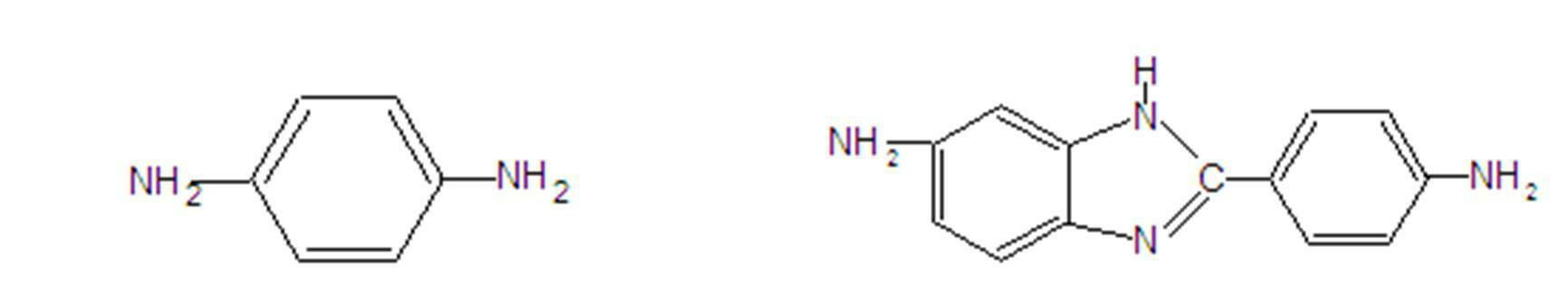

[0036] According to TPC: PABZ: PDA =100:50:50 molar ratio, first add PDA and PABZ two kinds of diamine monomers into the N-methylpyrrolidone / lithium chloride solvent system, the content of lithium chloride is 4wt%, and then Stir under the protection of nitrogen to dissolve all PDA and PABZ, cool the system to 5°C, then add TPC to the system in three batches and stir to make it continue to react for 4 hours at 25°C under nitrogen atmosphere to obtain a viscous aroma Homogeneous stock solution of polyamide polymer. The solid content of the polymer in the stock solution was 4wt%.

[0037] According to the molar ratio of BPDA:PABZ:PDA=100:50:50, two kinds of diamine monomers, PDA and PABZ, are firstly added into the metered N-methylpyrrolidone / lithium chloride solvent system, and the content of lithium chloride is 4wt%. Then stir under the protection of nitrogen to dissolve all the PDA and PABZ, cool the system down to 10°C, then add the measured BPDA into the system in three bat...

Embodiment 2

[0040] In this example, except that the aromatic polyamide polymer stock solution and the aromatic polyamic acid polymer stock solution are blended according to the polymer weight ratio of 70:30, and the thermal stretching / hot imide temperature is 450°C, the remaining fibers are prepared The process and the ratio of polyamide and polyamic acid synthesis monomers are the same as those in Example 1, so they are omitted here.

Embodiment 3

[0042] In this example, the aromatic polyamide polymer stock solution and the aromatic polyamic acid polymer stock solution are blended according to the polymer weight ratio of 50:50, and the thermal stretching / hot imide temperature is 380°C. The aromatic polyamide The molar ratio of polymerized monomers is TPC:PABZ:PDA=100:40:60, the molar ratio of aromatic polyamic acid polymerized monomers is BPDA:PABZ:PDA=100:70:30, and the reasons and implementation of other fiber preparation processes Example 1 is the same, so it is omitted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com