Moisturecured one-component polyurethane paint and preparation method thereof

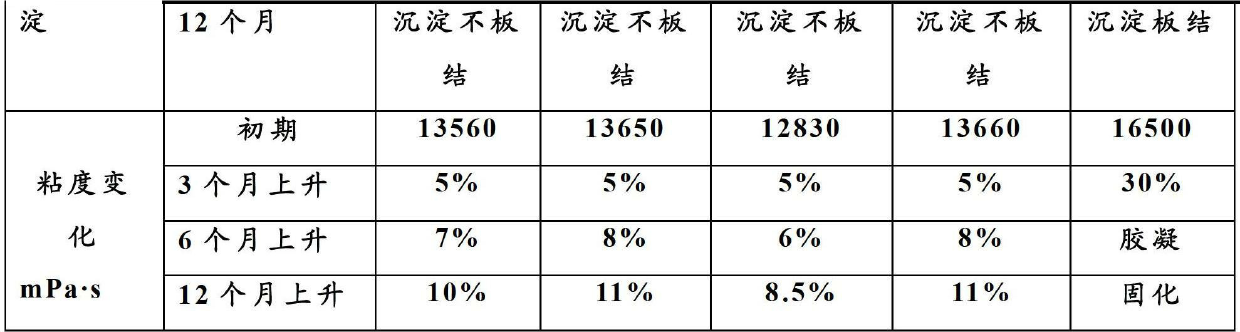

A polyurethane coating, one-component technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of cumbersome procedures, high tensile strength, reduced storage stability, etc., and achieve good physical and mechanical properties and system viscosity changes. Small, the effect of improving storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This embodiment provides a moisture-curing one-component polyurethane coating and a preparation method thereof.

[0031] In terms of parts by weight, the raw materials of moisture-curing one-component polyurethane coatings are: 18 parts of diphenylmethane diisocyanate MI-50 (BASF), polyether polyol (DL-2000, Shandong Bluestar Dongda Chemical Co., Ltd. company) 35 parts, propylene carbonate 10 parts, silane coupling agent modified calcined kaolin 35 parts, oxazolidine curing agent (FT-103, Zhangjiagang Feite Company) 1 part, cyclodextrin-coated organic bismuth complex 0.5 parts of substance (Shanghai Hemu Chemical Co., Ltd.), 0.3 parts of defoamer (BYK-378) and 0.2 parts of p-toluenesulfonyl isocyanate (Sinopharm Chemical Reagent Co., Ltd.).

[0032] The preparation method of moisture curing one-component polyurethane coating is as follows:

[0033]Step 1: Add DL-2000, propylene carbonate and silane coupling agent modified calcined kaolin into the closed reaction kettle...

Embodiment 2

[0037] This embodiment provides a moisture-curing one-component polyurethane coating and a preparation method thereof.

[0038] In terms of parts by weight, the raw materials of moisture-curing one-component polyurethane coatings are: 16 parts of diphenylmethane diisocyanate MI-50 (BASF), polyether polyol (DL-2000, Shandong Bluestar Dongda Chemical Co., Ltd. Company) 30 parts, polyether polyol (EP-330N) 10 parts, propylene carbonate 10 parts, silane coupling agent modified talcum powder 30 parts, oxazolidine curing agent (FT-103, Zhangjiagang Feite Company) 2 1 part, cyclodextrin-coated organic bismuth complex (Shanghai Hemu Chemical Co., Ltd.), 0.3 part of defoamer (BYK-378) and p-toluenesulfonyl isocyanate (Sinopharm Chemical Reagent Co., Ltd.) 0.5 servings.

[0039] The preparation method of moisture curing one-component polyurethane coating is as follows:

[0040] Step 1: Add DL-2000, EP-330N, propylene carbonate and silane coupling agent modified talcum powder into the ...

Embodiment 3

[0044] This embodiment provides a moisture-curing one-component polyurethane coating, which is prepared by the same method as in Embodiment 1. In parts by weight, the raw material composition of the moisture-curing one-component polyurethane coating is as follows:

[0045] 12 parts of IPDI (Bayer company), 30 parts of polyether polyol (DL-2000, Shandong Bluestar Dongda Chemical Co., Ltd.), 5 parts of polyether polyol (DL-3000), 10 parts of propylene carbonate, silane di 40 parts of talcum powder modified by joint agent, 2 parts of oxazolidine curing agent (FT-103, Zhangjiagang Feite Company), 1 part of organic bismuth complex coated with cyclodextrin (Shanghai Hemu Chemical Co., Ltd.), disinfectant 0.5 parts of foaming agent (BYK-378) and 0.5 parts of p-toluenesulfonyl isocyanate (Sinopharm Chemical Reagent Co., Ltd.).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com