Erbium sodium codoping calcium fluoride transparent ceramic and preparation method thereof

A technology of transparent ceramics and calcium fluoride, applied in the field of laser transparent ceramics preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Weigh Ca(NO 3 ) 2 4H 2 O, Er(NO 3 ) 3 ·5H 2 O and KF 2H 2 O, respectively dissolved in deionized water, prepared as Ca with a molar concentration of 0.5 mol / L 2+ and Er 3+ cationic solution, the molar concentration is 0.5mol / L of F - Anionic solution, Ca in cationic solution 2+ and Er 3+ The molar content ratio is n(Ca 2+ ): n (Er 3+ )=95:5, and then the two solutions were quickly mixed and reacted. Er 3+ :CaF 2 The nanoparticle suspension was washed with deionized water, centrifuged three times, and then dried in vacuum at 75°C to obtain Er with a grain size of 15-50nm. 3+ :CaF 2 Nano powder. single doped Er 3+ :CaF 2 The nano-powder is loaded into a graphite mold and sintered in a vacuum hot-press furnace with a heating rate of 15°C / min, a sintering temperature of 800°C, a pressure of 30MPa, and a holding time of 60 minutes.

[0040] After the obtained samples were roughly ground with different types of sandpaper, they were polished on both sides on...

Embodiment 2

[0042] Er 3+ The blending amount is 5mol% of Er 3+ :CaF 2 The preparation of nanopowder is identical with embodiment 1 method, the Er of gained 3+ :CaF 2 Nano powder and NaF powder (Na + The ion content is 0.5mol%) is fully mixed in alcohol, and then dried to form a sintered powder. The sintered powder is sintered in a vacuum hot-press furnace, and the process parameters are the same as in Example 1.

[0043] After double-sided polishing of the obtained sample, the finished product of erbium-sodium co-doped calcium fluoride transparent ceramics was obtained, with a density of 99.9% and a transmittance of 83.998% at a wavelength of 1363nm. The luminous intensity of 1530nm under the excitation of 978nmLD changes with time, such as image 3 As shown in the curve in (b), the fitted fluorescence lifetime is 5.91ms.

Embodiment 3

[0045] Er 3+ The blending amount is 5mol% of Er 3+ :CaF 2 The preparation of nanopowder is identical with embodiment 1 method, the Er of gained 3+ :CaF 2 Nano powder and NaF powder (Na + The ion content is 1.0mol%) is fully mixed in alcohol, and then dried to form a sintered powder. The sintered powder is sintered in a vacuum hot-press furnace, and the process parameters are the same as in Example 1.

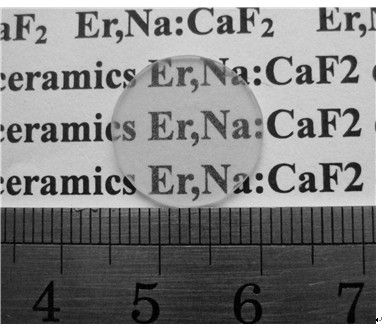

[0046] Gained samples are obtained after double-sided polishing to obtain erbium-sodium co-doped calcium fluoride transparent ceramic finished products such as figure 1 As shown, the density is 99.94%, and the transmittance of the sample is tested by the UV3600 ultraviolet-visible-near-infrared spectrophotometer of Japan Shimadzu Company, and the results are as follows figure 2 shown. The transmittance at the wavelength of 1363nm is 85.096%. The luminous intensity of 1530nm under the excitation of 978nmLD changes with time, such as image 3 As shown in the middle (c) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com