Method for cleaning surface of passivated GaAs substrate

A substrate surface, substrate technology, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of GaAs surface defects, strong irritating taste, environmental hazards, etc. The effect of surface flatness, improved electrical properties, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] 1. Cleaning and passivation process of GaAs surface:

[0017] Substrate: Commercial single crystal GaAs substrate, P-type or N-type, orientation (1 0 0), Zn doping concentration is about ~1~10×10 17 cm -3 .

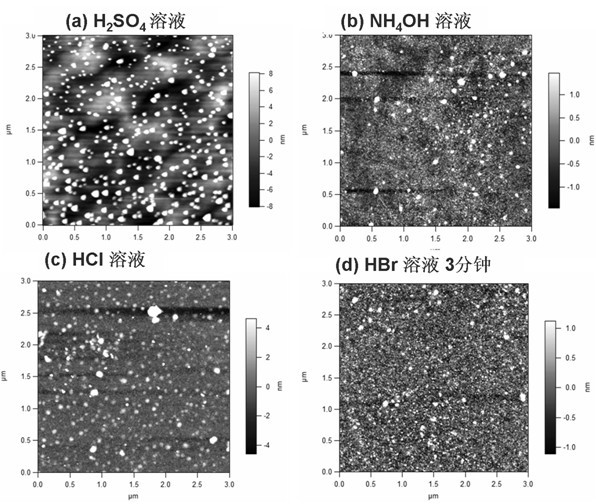

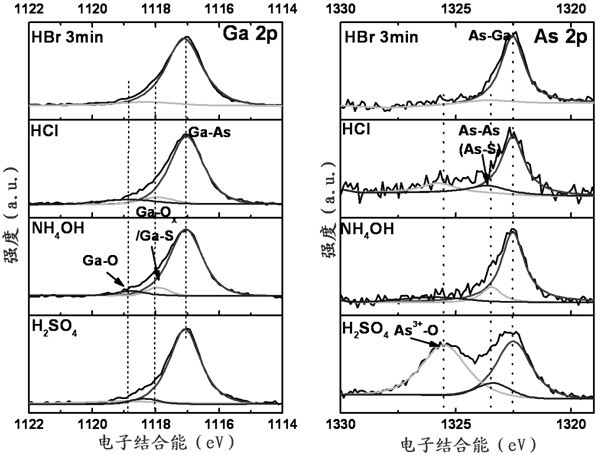

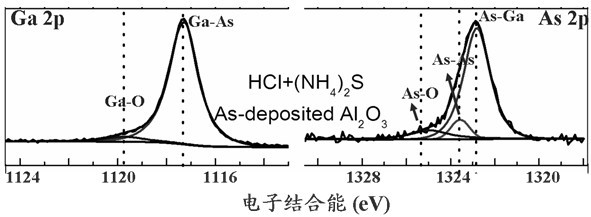

[0018] Process flow: The GaAs substrate is first treated with an organic solution - ultrasonically cleaned with acetone, methanol, and isopropanol for 5 minutes to remove the oil on the surface, then soaked in an acidic or alkaline solution to remove the oxide layer on the surface, and then placed in a heating to 50°C (NH 4 ) 2 Soak in S solution for 20-30 minutes for passivation. Finally, rinse the surface with deionized water and blow dry with high-purity nitrogen.

[0019] Wherein the acidic or alkaline solution that is used to remove oxide layer has following four kinds, and first three kinds of schemes are used for comparing with the fourth kind of scheme of the present invention:

[0020] 1. Soak in a mixed solution with a volume ratio of sulfuric acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com