High-power electronic ballast

An electronic ballast and high-power technology, applied in the field of high-power electronic ballasts, can solve problems such as shortening the service life of electronic ballasts and damaging MOSFET tubes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

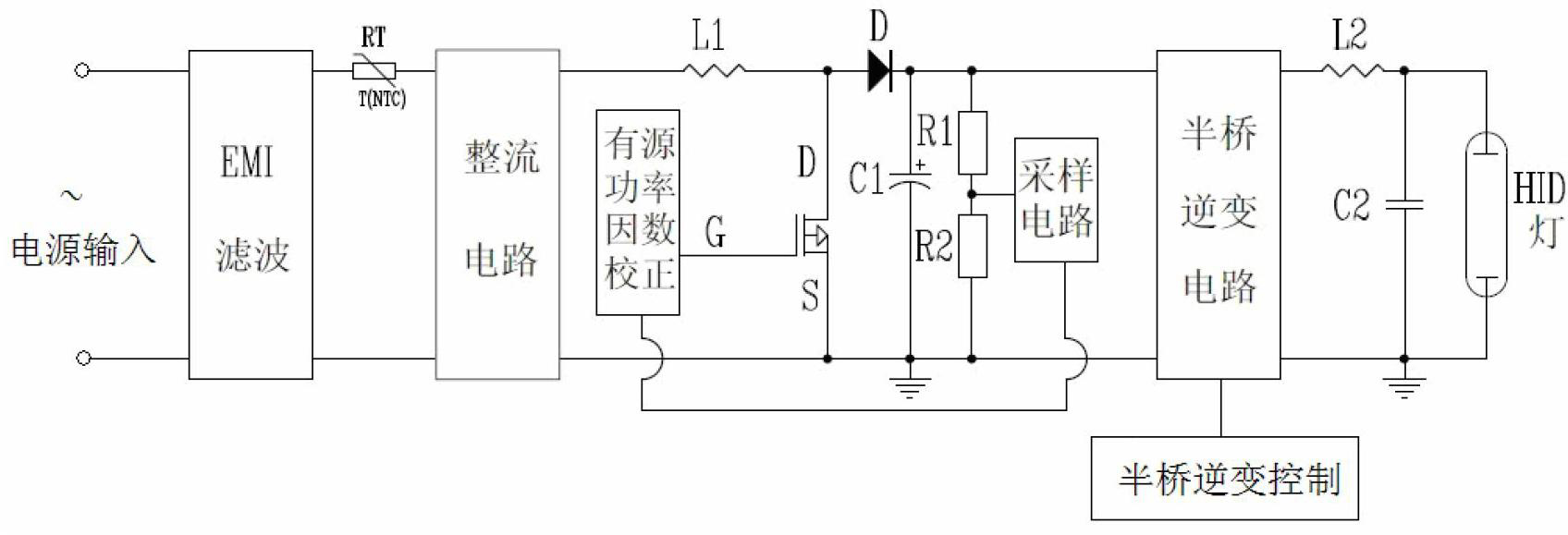

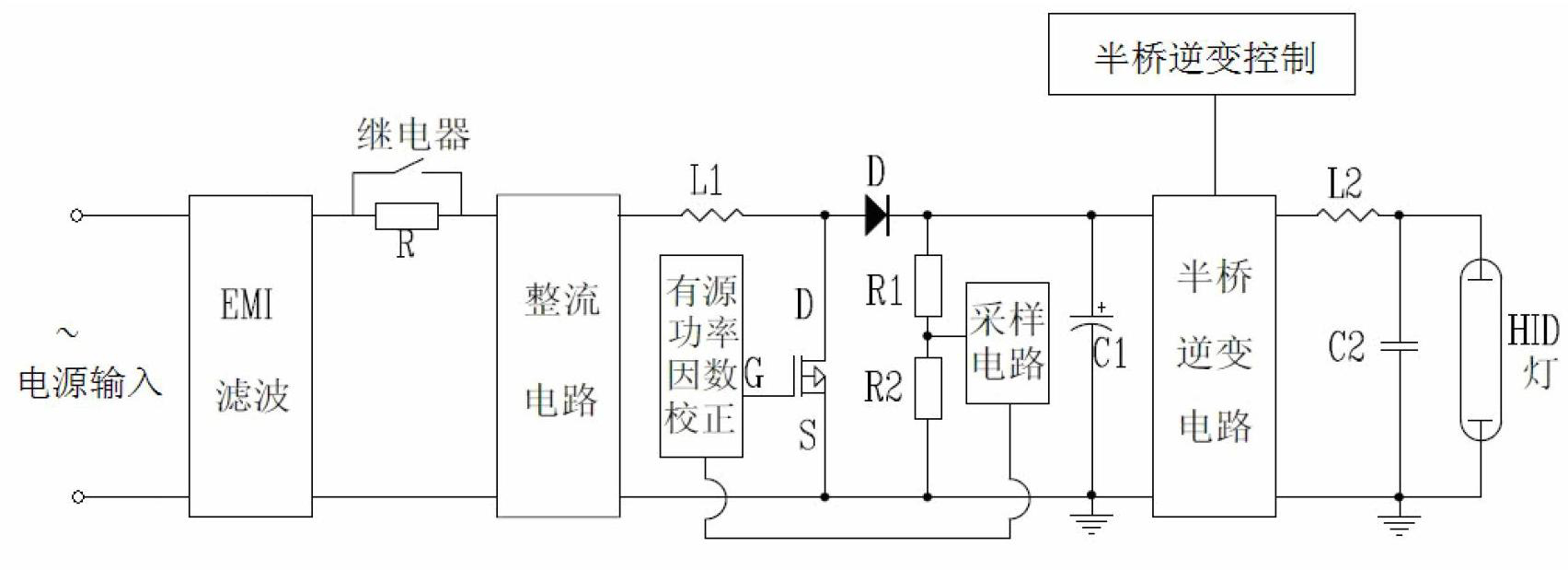

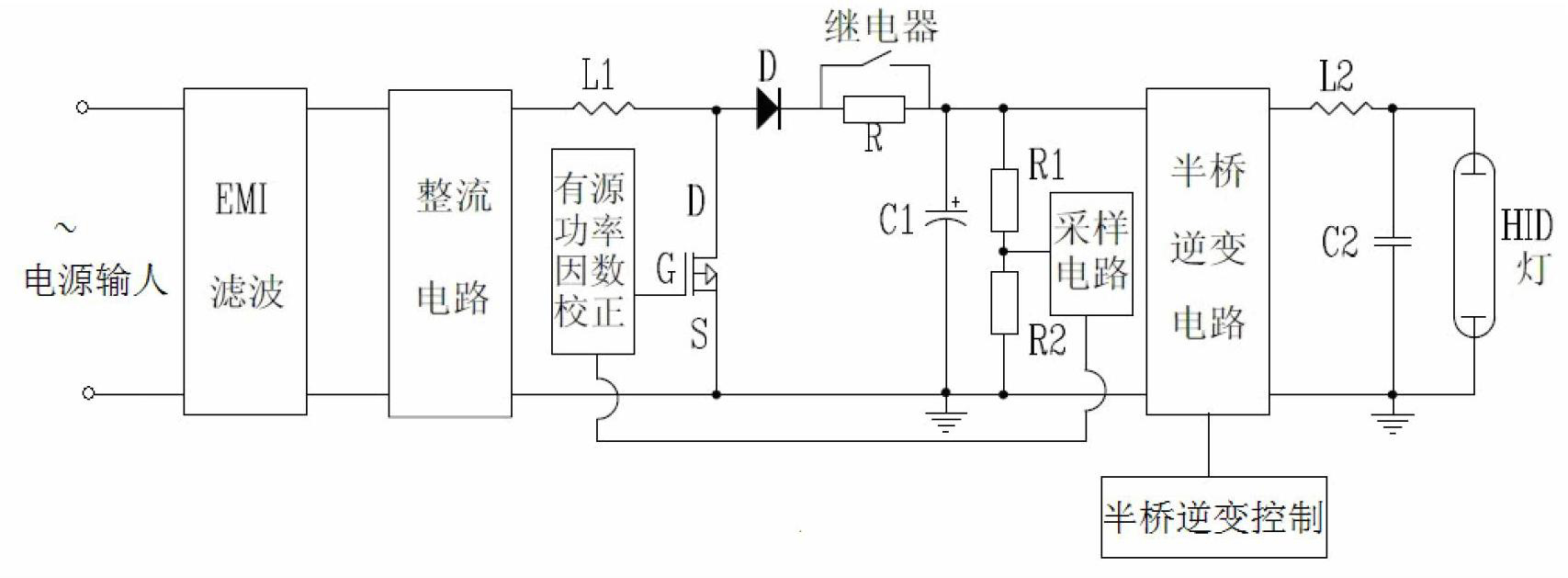

[0012] A high-power electronic ballast, which includes an EMI filter circuit 10, a rectifier circuit 20, an MCU control circuit 50, a sampling detection circuit 40, a half-bridge inverter circuit 60, a first inductor L11, a second inductor L12, a diode D11, Field effect transistor QE, first resistor R11, second resistor R12, third resistor R13, relay K, first capacitor C11, second capacitor C12 and HID lamp H, EMI filter circuit 10 and rectifier circuit 20 connected in series to rectify The output end of the circuit 20 is connected to one end of the first inductance L11, and the other end of the first inductance L11 is respectively connected to the drain D of the field effect transistor QE and the anode of the diode D11, and is characterized in that: the gate G of the field effect transistor QE The PFC boost circuit 30 is connected to the MCU control circuit 50, the cathode of the diode D11 is respectively connected to one end of the second resistor R12 and one end of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com