SO8 plastic package sensor

A technology for plastic packaging and sensors, applied in instruments, measuring devices, electrical solid devices, etc., can solve the problems of reducing the compactness of the coating, the performance of the sensor, and the moisture resistance, etc., to improve the mechanical properties and thermal stability, excellent resistance. The effect of good oxidability, weldability, and thermal expansion coefficient matching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The best embodiment of the present invention will be described in detail below in conjunction with specific drawings.

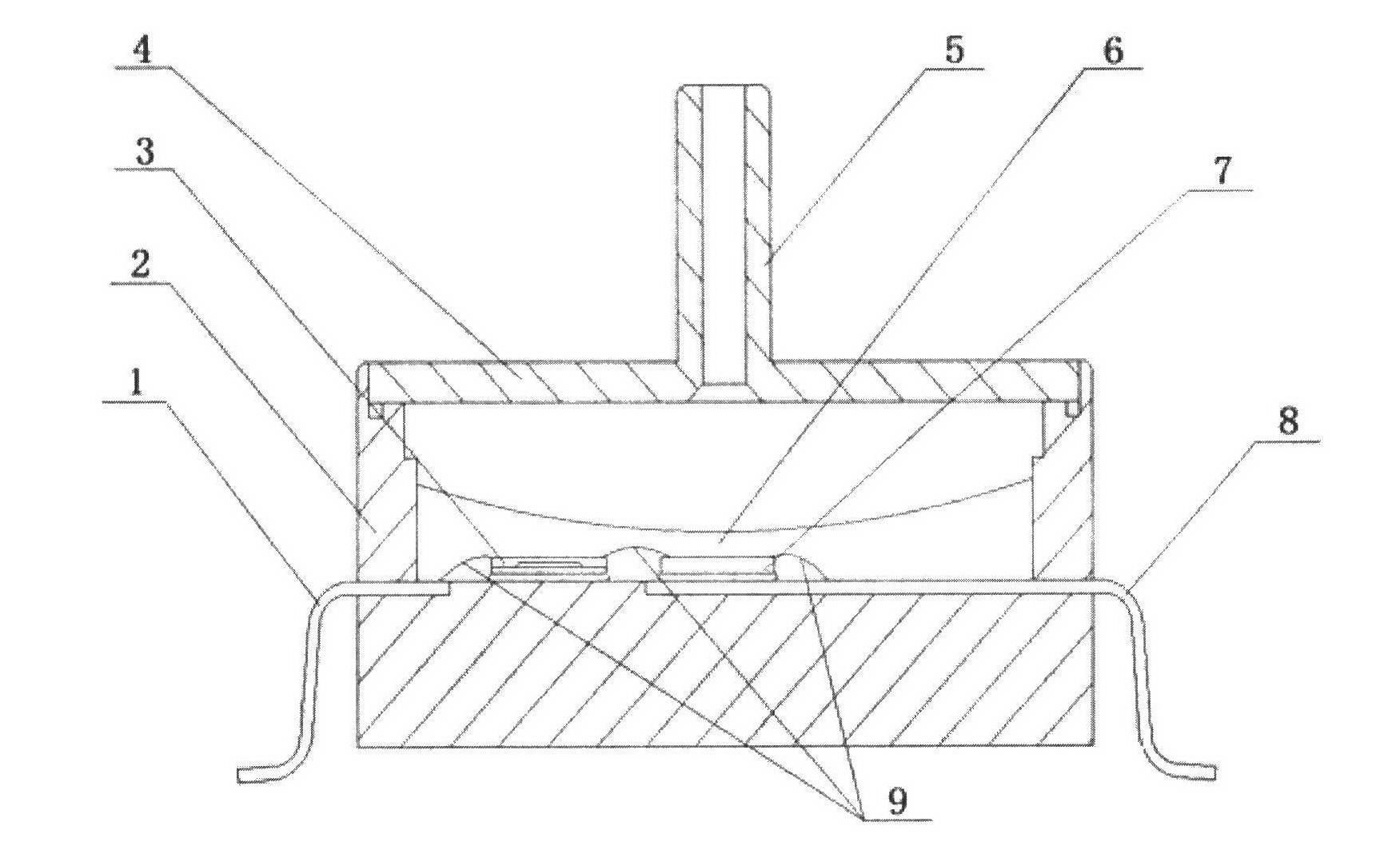

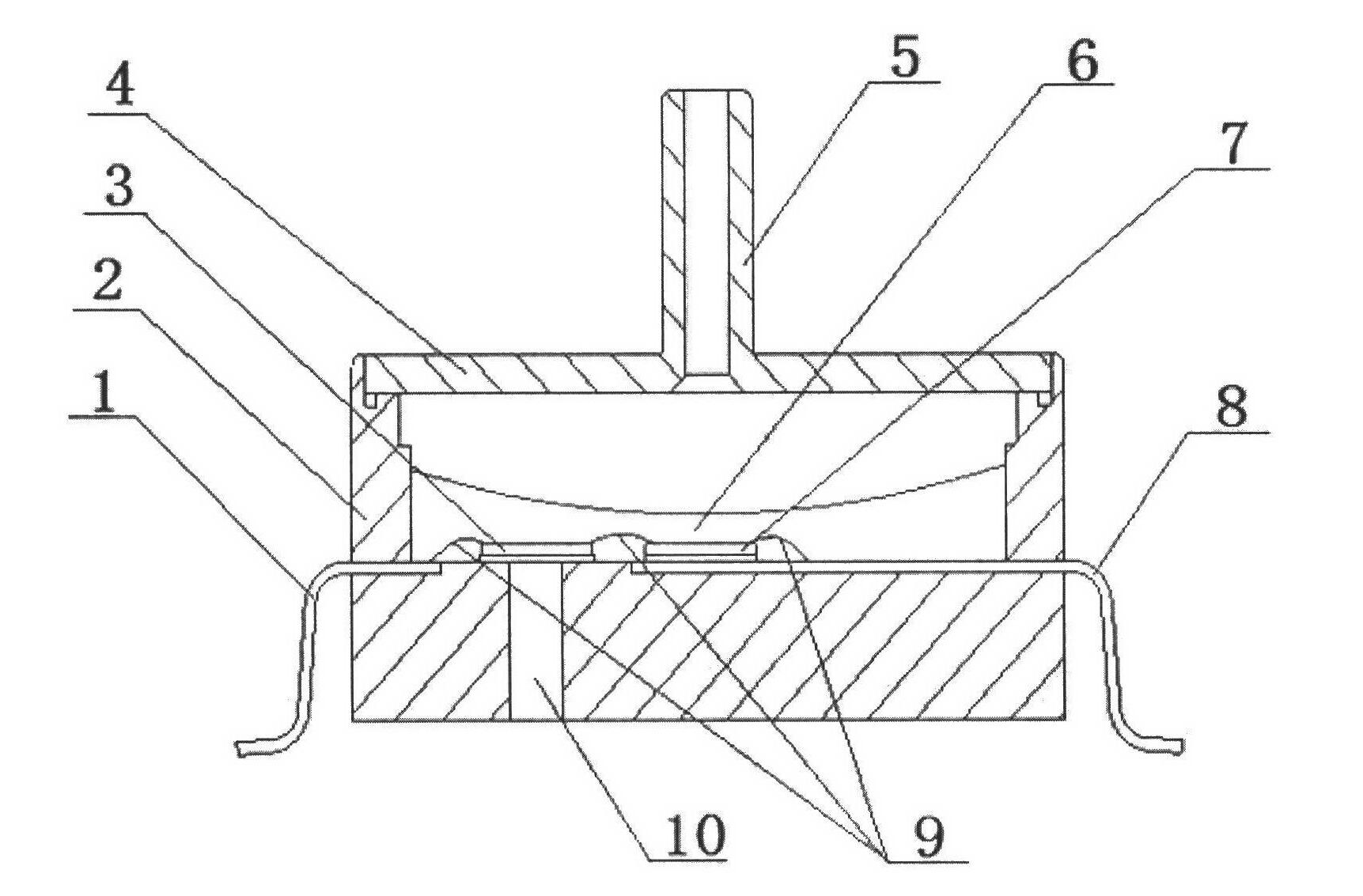

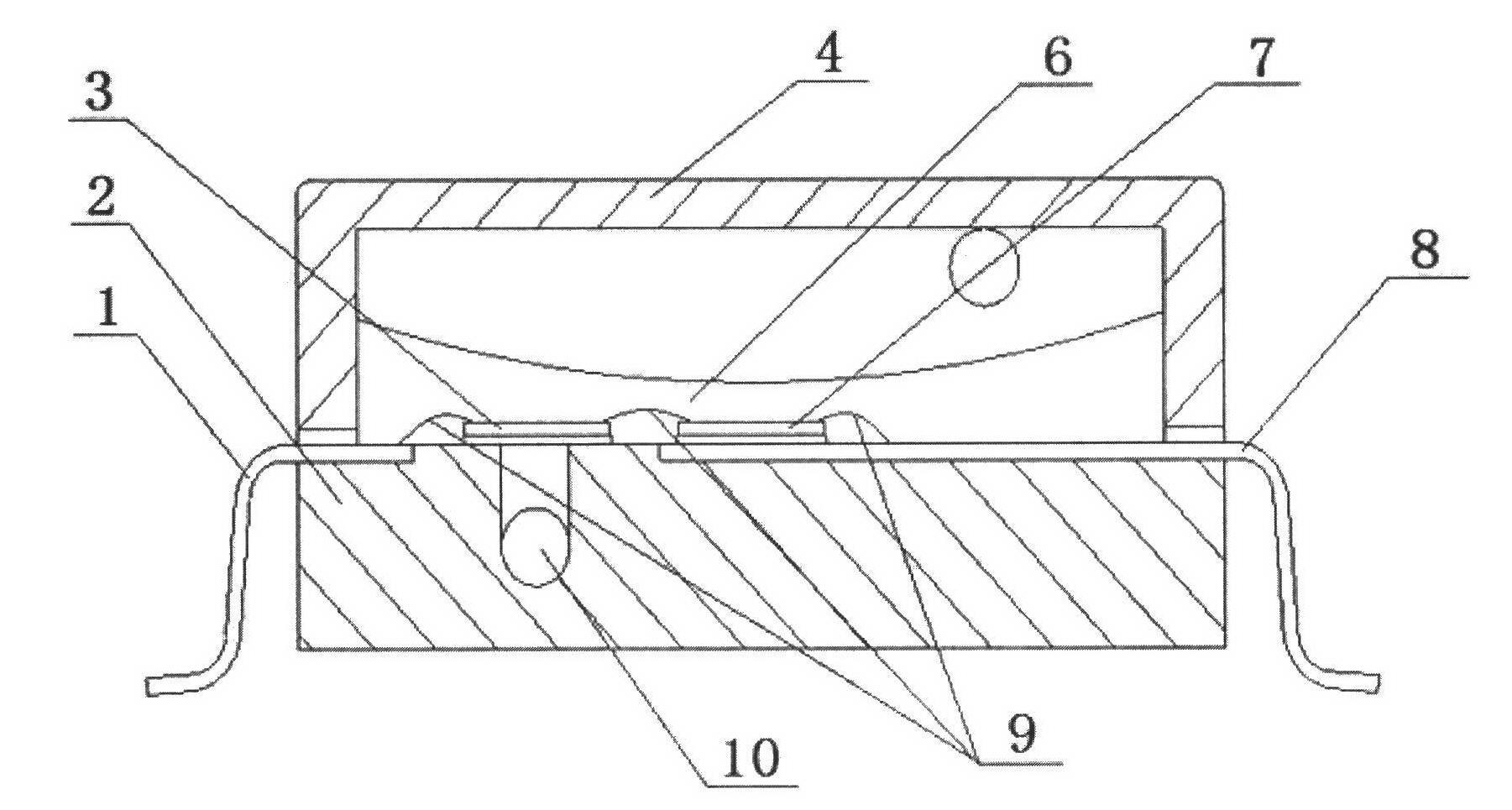

[0017] Such as figure 1 As shown, the first embodiment of the SO8 plastic package sensor of the present invention includes a pre-mold 2, a first lead frame 1 and a second lead frame 8, the pre-mold 2 has an inner cavity, and the upper end of the inner cavity has an opening. The first lead frame 1 and the second lead frame 8 are respectively integrated with the pre-mold 2 through pre-molding, and the parts of the first lead frame 1 and the second lead frame 8 protruding from the pre-mold are respectively punched by cutting ribs. Bend to form 4 pins for a total of 8 pins. The surfaces of the first lead frame 1 and the second lead frame 8 are plated with gold. The bottom surface of the inner cavity of the pre-mold 2 is pasted with a pressure sensor chip 3 through the adhesive, and the upper surface of the second lead frame 8 in the inner cavity of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com