Detergent for superfine fiber fabric and preparation method of detergent

A technology for microfiber fabrics and detergents, which is applied in the direction of detergent compounding agents, detergent compositions, detergent compositions, fragrances, etc., and can solve problems such as easy generation of static electricity, yellowing, and hardening of microfiber fabrics, and achieve Prevent product deterioration, moderate foam, strong antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

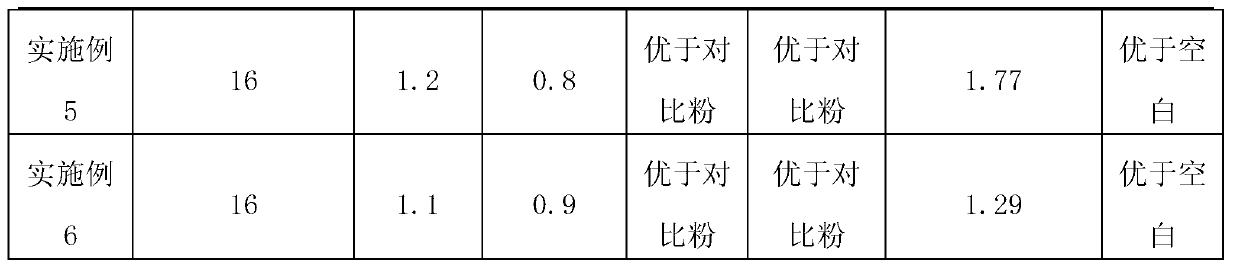

Examples

Embodiment 1

[0054] Microfiber fabric detergent, comprising the following components in parts by weight:

[0055] Fatty alcohol polyoxyethylene (9) ether 2 parts,

[0056] Propylene glycol block polyether L64 8 parts,

[0057] Potassium lauryl polyoxyethylene ether phosphate 0.9 part,

[0058] 6 parts of sodium secondary alkyl sulfonate,

[0059] Relative molecular weight is 0.5 part of sodium polyacrylate of 4000,

[0060] Sodium gluconate and sodium citrate 10 parts,

[0061] Triclocarban 0.5 part,

[0062] Essence 0.1 part,

[0063] 72 parts of deionized water.

[0064] The content of the surfactant prepared in this example is 16.9wt%, and the detergency meets the requirements of the QB1224-2007 standard. The test cotton white cloth is uniformly replaced with the same white microfiber fabric cloth, and the ordinary washing powder containing 4A zeolite, carbonate, and silicate is used as a reference sample, and the detergent prepared in this embodiment is measured according to GB / ...

Embodiment 2

[0066] Microfiber fabric detergent, comprising the following components in parts by weight:

[0067] Fatty alcohol polyoxyethylene (7) ether 12 parts,

[0068] 2 parts of propylene glycol block polyether L64,

[0069] Potassium Laureth Phosphate 6 parts,

[0070] 0.06 parts of sodium secondary alkyl sulfonate,

[0071] 2.7 parts of sodium polyacrylate,

[0072] Sodium gluconate 1 part,

[0073] 0.3 parts of essence,

[0074] 75.94 parts of deionized water.

[0075] The content of the surfactant prepared in this example is 20.06wt%, and the detergency meets the requirements of the QB1224-2007 standard. The test cotton white cloth is uniformly replaced with the same white microfiber fabric cloth, and the ordinary washing powder containing 4A zeolite, carbonate, and silicate is used as a reference sample, and the detergent prepared in this embodiment is measured according to GB / T 13174-2008. The cyclic washing ability of microfiber fabric detergent to white microfiber fabr...

Embodiment 3

[0077] Microfiber fabric detergent, comprising the following components in parts by weight:

[0078] Fatty alcohol polyoxyethylene (7) ether 6 parts,

[0079] Propylene glycol block polyether L61 6 parts,

[0080] Potassium Laureth Phosphate 3 parts,

[0081] 3 parts of sodium secondary alkylsulfonate,

[0082] Relative molecular weight is 1.5 parts of sodium polyacrylate of 4000,

[0083] Sodium citrate 4 parts,

[0084] Triclocarban 1 part,

[0085] 0.5 parts of essence,

[0086] 75 parts of deionized water.

[0087] The content of the surfactant prepared in this example is 18wt%, and the detergency meets the requirements of the QB1224-2007 standard. The test cotton white cloth is uniformly replaced with the same white microfiber fabric cloth, and the ordinary washing powder containing 4A zeolite, carbonate, and silicate is used as a reference sample, and the detergent prepared in this embodiment is measured according to GB / T 13174-2008. The cyclic washing ability of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com