Antistatic weaved glove

An anti-static and knitting technology, applied in gloves, protective clothing, clothing, etc., can solve the problems of airtightness, danger caused by staff, single function of anti-static gloves, etc., and achieve the effect of increasing air permeability and preventing hands from being cut.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the objects and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

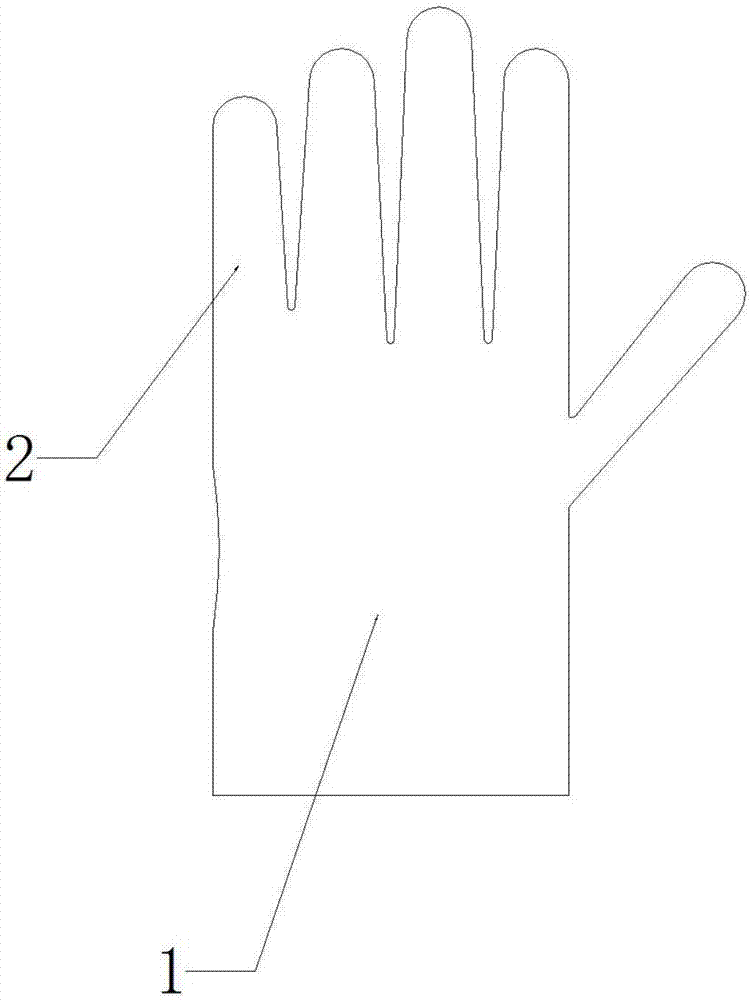

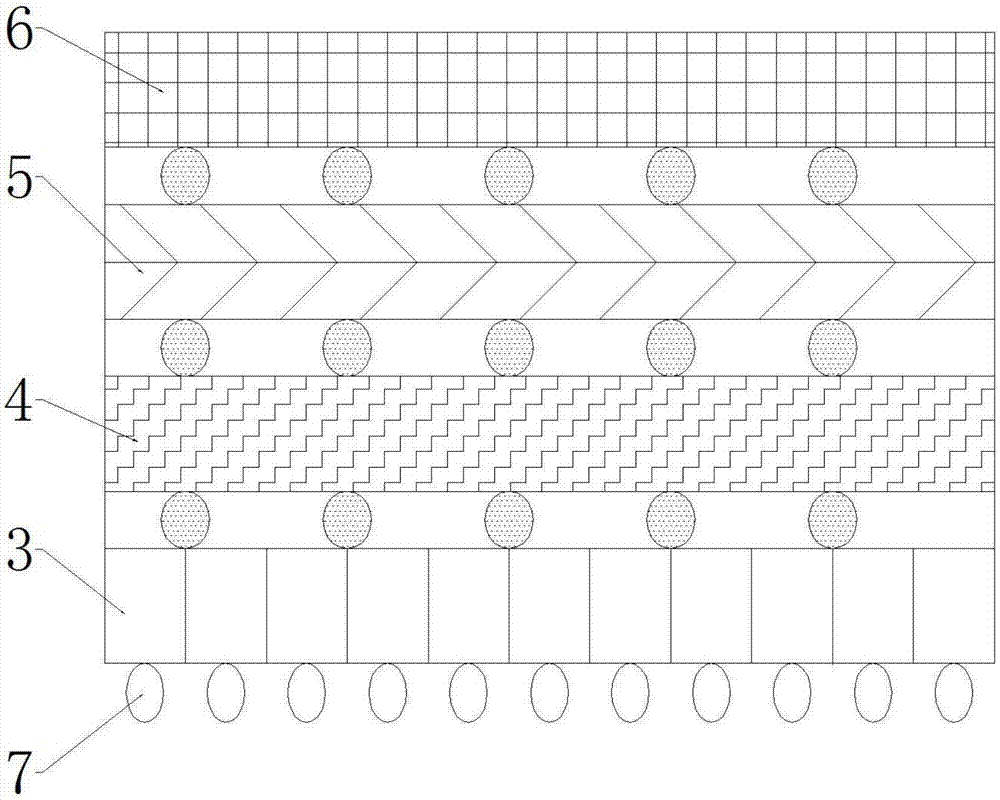

[0019] Such as Figure 1-Figure 2 As shown, the embodiment of the present invention provides an antistatic knitted glove, including a palm area 1 and a finger area 2 connected thereto. The anti-cut layer 6 is composed of the inner layer 3, which is made of the first warp yarn and the first weft yarn criss-cross, and there are several holes between the first warp yarn and the second weft yarn, and there are raised coil structures 7 in the holes; the first warp thread is made of It is made of bamboo fiber or silk fiber with hygroscopic function, and the first weft yarn is made of nano-silver fiber or flax fiber with antibacterial function; the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com