Method for recovering silicon powder from monocrystalline and polycrystalline silicon linear cutting wastes by utilizing microporous membrane filter process

A microporous membrane filtration and cutting waste technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of long process flow, complicated operation, difficult recovery process, etc., and achieve simple process flow and high separation efficiency , the effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

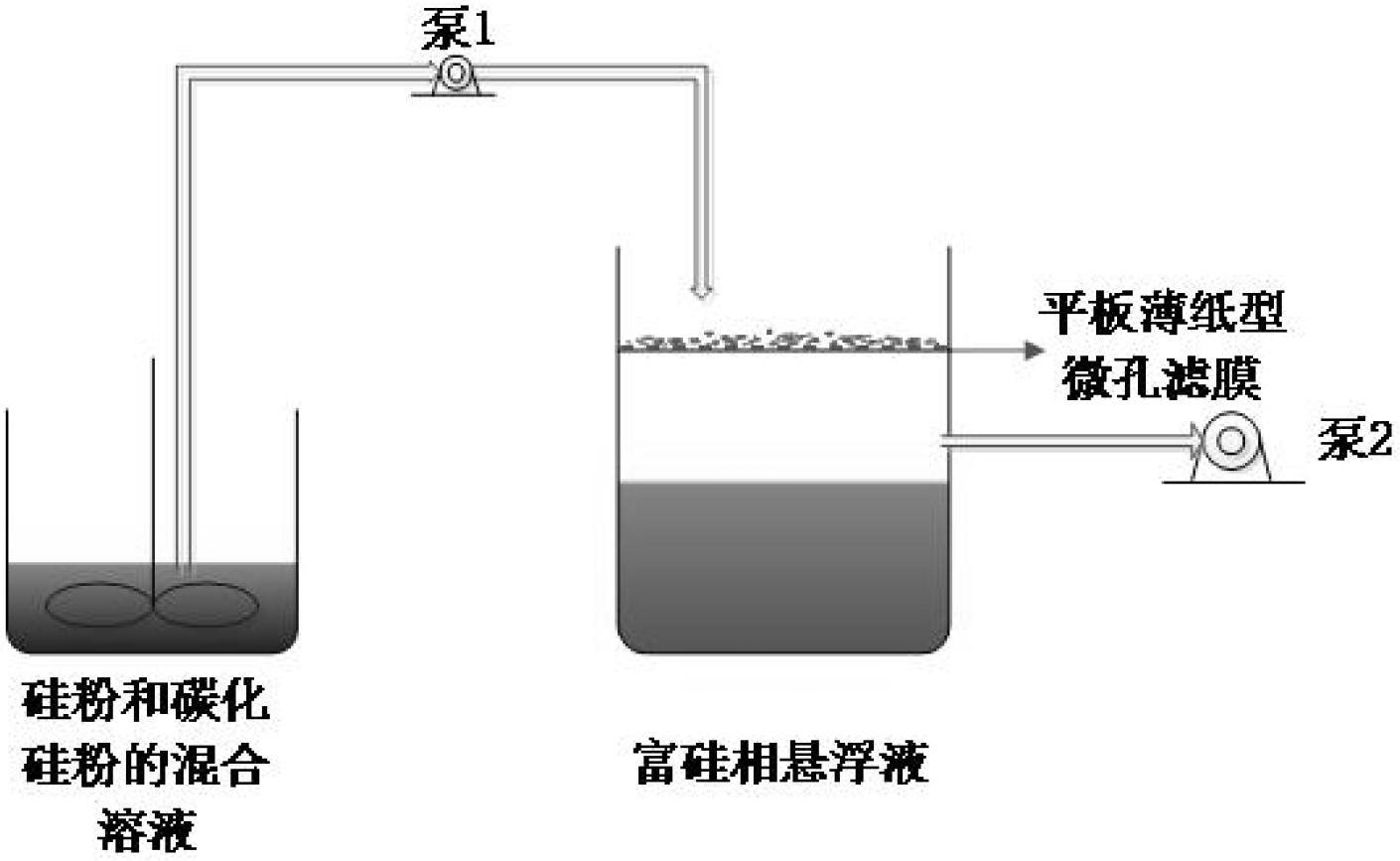

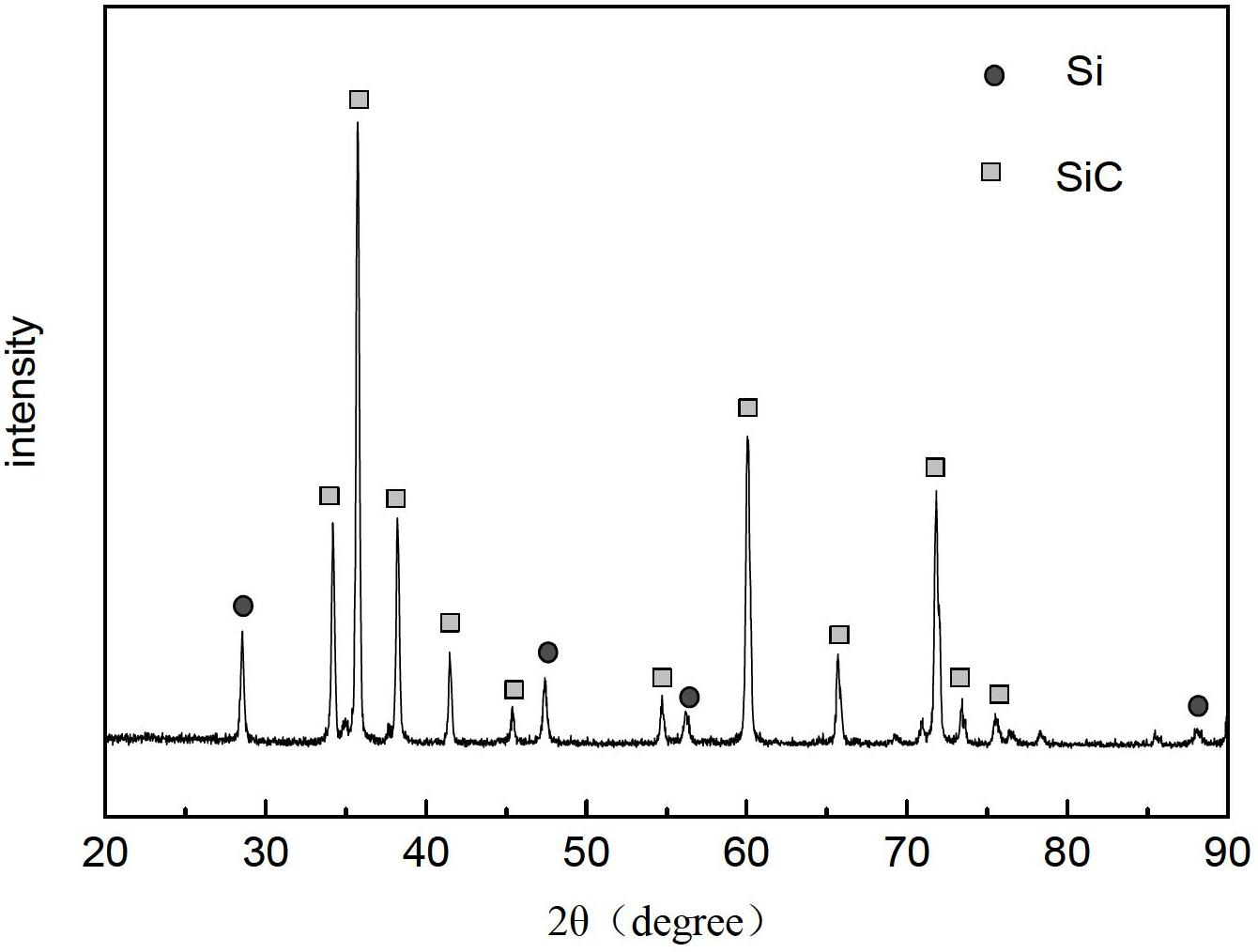

[0039] Put the mixed powder with polyethylene glycol removed in a ball mill and grind it for 15 minutes, then add water according to the liquid-solid ratio of 3:1, put it in an ultrasonic cleaner for 20 minutes, add water and adjust the pH value with sodium hydroxide solution 6. The liquid-solid ratio is 10:1. Put the mixed solution into a microporous membrane separation device with a pore size of 5 microns, take out the silicon-rich phase suspension, and put it into a microporous filter with a pore size of 2 microns. Secondary filtration is carried out in the membrane separation equipment to obtain the silicon-rich phase suspension and its pH value is adjusted to 1. The silicon powder settles rapidly and is dried and recovered; the silicon carbide-rich sediment is returned to the original mixed powder solution for recycling. It can be seen from the XRD pattern that only a small amount of silicon carbide is contained in the recovered silicon powder.

[0040]

specific Embodiment 2

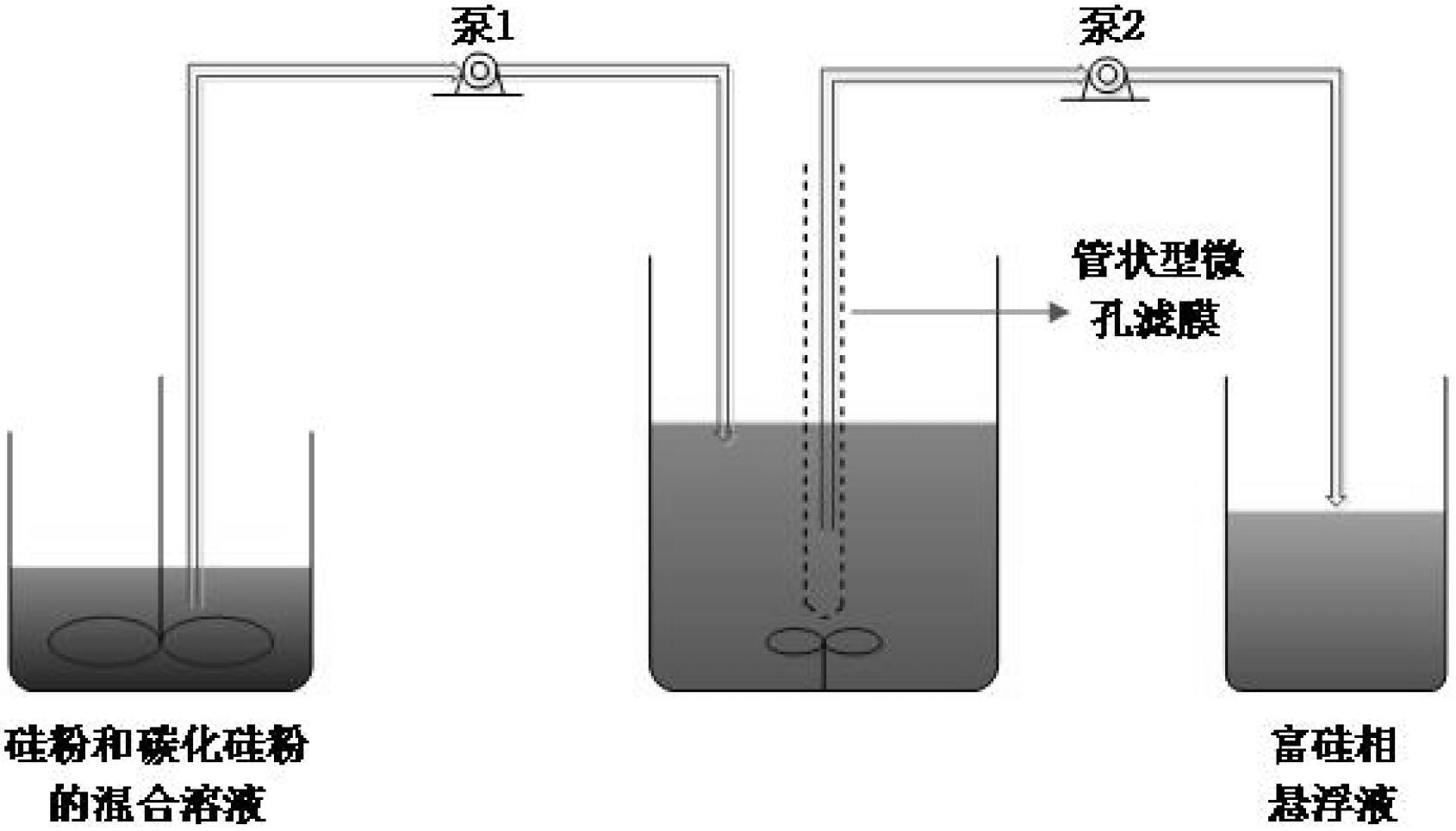

[0041] Put the mixed powder with polyethylene glycol removed in a ball mill and grind it for 20 minutes, then add water according to the liquid-solid ratio of 3:1, put it in an ultrasonic cleaner for 15 minutes, add water and adjust the pH value with sodium hydroxide solution 8. The liquid-solid ratio is 10:1. Put the mixed solution into a tubular microporous membrane separation device with a pore size of 4 microns for filtration, take out the silicon-rich phase suspension and put it into a tubular microporous membrane with a pore size of 2 microns for separation Perform secondary filtration in the equipment to obtain the silicon-rich phase suspension and adjust its pH value to 1. The silicon powder is quickly agglomerated and filtered with a flat thin paper microporous membrane with a pore size of 1 micron to quickly recover the fine powder in the silicon-rich phase. ; Rich silicon carbide deposits are returned to the original mixed powder solution for recycling. Its XRD resu...

specific Embodiment 3

[0043]Put the mixed powder with polyethylene glycol removed in a ball mill and grind it for 20 minutes, then add water according to the liquid-solid ratio of 3:1, put it in an ultrasonic cleaner for 15 minutes, add water and adjust the pH value with sodium hydroxide solution 7. The liquid-solid ratio is 10:1. Put the mixed solution into a flat paper thin paper microporous membrane separation device with a pore size of 3 microns for filtration, take out the silicon-rich phase suspension and put it into a flat paper thin paper microporous membrane with a pore size of 1 micron. Secondary filtration is carried out in the filter membrane separation equipment to obtain the silicon-rich phase suspension and adjust its pH value to 1. The silicon powder settles rapidly and is dried and recovered; the silicon carbide-rich sediment is returned to the original mixed powder solution for recycling. Its XRD result is identical with embodiment one.

[0044]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com