Cr2AlC ceramic target and preparation method thereof by vacuum hot pressing

A chrome-aluminum-carbon ceramic and vacuum hot pressing technology is applied in the fields of chrome-aluminum-carbon ceramic targets and their vacuum hot-pressing preparation and high-temperature coating target preparation. Serious lumps, environmental pollution and other problems, to achieve the effect of uniform heating, moderate grain size, and high single-phase content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

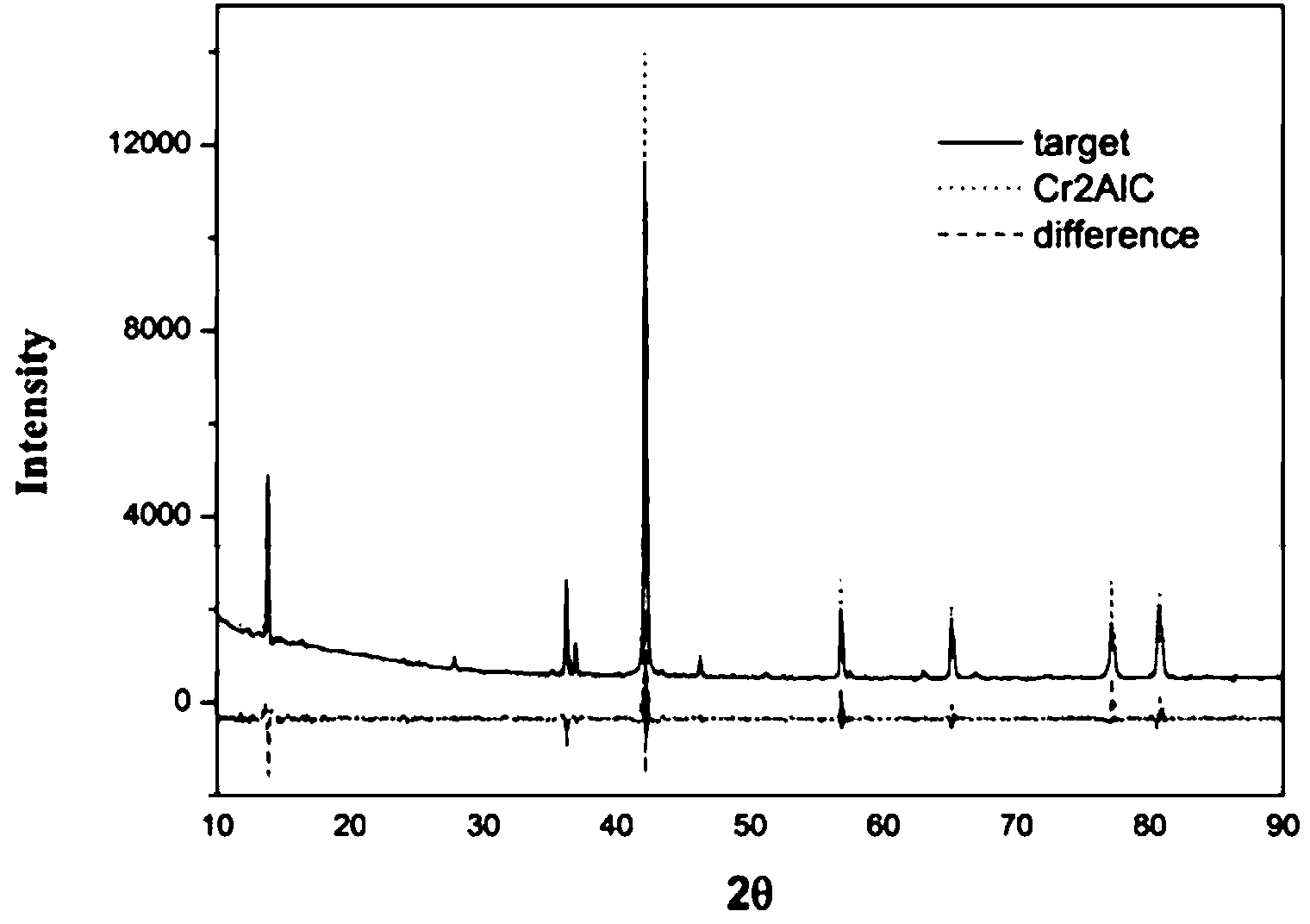

Image

Examples

Embodiment 1

[0036]Weigh 104 grams of Cr powder, 32.4 grams of Al powder, and 12 grams of C powder. The purity of chromium powder, aluminum powder and carbon powder is greater than 99.9%, and the particle size is less than 20 μm. Put them into a ball mill jar and add 300 grams of agate balls , ball milled for 12 hours. The raw material powder is put into the graphite mold, and the raw material is pre-pressed axially with a jack, and the pre-pressing pressure is 2MPa. After pre-pressing, the graphite mold is moved into the vacuum hot-pressing sintering furnace. The hot-press furnace is first evacuated to a certain degree of vacuum with a mechanical pump, and then evacuated to 10 with a Roots pump. -1 Pa, then raise the temperature to 630°C at a heating rate of 5°C / min, keep the temperature for 2 hours, without pressurization; then raise the temperature at a speed of 10°C / min, gradually increase the pressure, and raise the temperature to 1350°C, the pressure is 20MPa, keep the heat After pr...

Embodiment 2

[0039] Weigh 156 grams of Cr powder, 48 grams of Al powder, and 18 grams of C powder, put them into a ball mill jar, add 300 grams of agate balls, and ball mill for 13 hours. The raw material powder is put into the graphite mold, and the raw material is pre-pressed axially with a jack, and the pre-pressing pressure is 2MPa. After pre-pressing, the graphite mold is moved into the vacuum hot-pressing sintering furnace. The hot-press furnace is vacuumed successively with a mechanical pump and a Roots pump for 10 -1 Pa, then raise the temperature to 630°C at a heating rate of 5°C / min, and keep the temperature for 2 hours; then raise the temperature at a speed of 10°C / min, gradually increase the pressure, and raise the temperature to 1400°C, and the pressure is 20MPa, and keep the pressure for 2 hours. , turn off the heating power supply, and start to cool down. After the temperature reaches 1000°C, release the pressure and cool for 10 hours. The furnace temperature drops to room t...

Embodiment 3

[0041] Weigh 312 grams of Cr powder, 100 grams of Al powder, and 36 grams of C powder, put them into a ball mill jar, add 600 grams of agate balls, and mill for 15 hours. The raw material powder is put into the graphite mold, and the raw material is pre-pressed axially with a jack, and the pre-pressing pressure is 3MPa. After pre-pressing, the graphite mold is moved into the vacuum hot-pressing sintering furnace. The hot-press furnace is vacuumed successively with a mechanical pump and a Roots pump for 10 -1 Pa, then raise the temperature to 650°C at a heating rate of 5°C / min, and keep the temperature for 2 hours; then raise the temperature at a speed of 10°C / min, gradually increase the pressure, and raise the temperature to 1500°C, and the pressure is 30MPa, and keep the pressure for 2 hours. , turn off the heating power supply, and start to cool down. After the temperature reaches 1100 ° C, release the pressure, cool for 10 hours, and the furnace temperature drops to room te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com