Aluminium/resin composite exhibiting excellent weather resistance and manufacturing method for the same

A technology of resin composites and manufacturing methods, applied in the direction of chemical instruments and methods, layered products, metal layered products, etc., can solve insufficient corrosion resistance, metal-resin interface adhesion strength and airtightness are not necessarily sufficient and other problems, to achieve the effects of increased tensile strength, excellent sealing strength and air tightness, and improved sealing strength and air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] [Preparation of Aluminum Formed Body]

[0084] From the aluminum alloy (JISA 1050-H24) plate with a thickness of 1mm, 3 aluminum flakes (aluminum alloy material) with a size of 50mm × 50mm are cut out, and these aluminum flakes are subjected to pretreatment, that is: at first in 30% by weight nitric acid aqueous solution in After 5 minutes of immersion at room temperature, it was fully washed with ion-exchanged water, then immersed in 5% by weight sodium hydroxide solution at 50°C for 1 minute, then washed with water, and then immersed in 30% by weight of nitric acid aqueous solution at room temperature for 3 minutes, and washed with water.

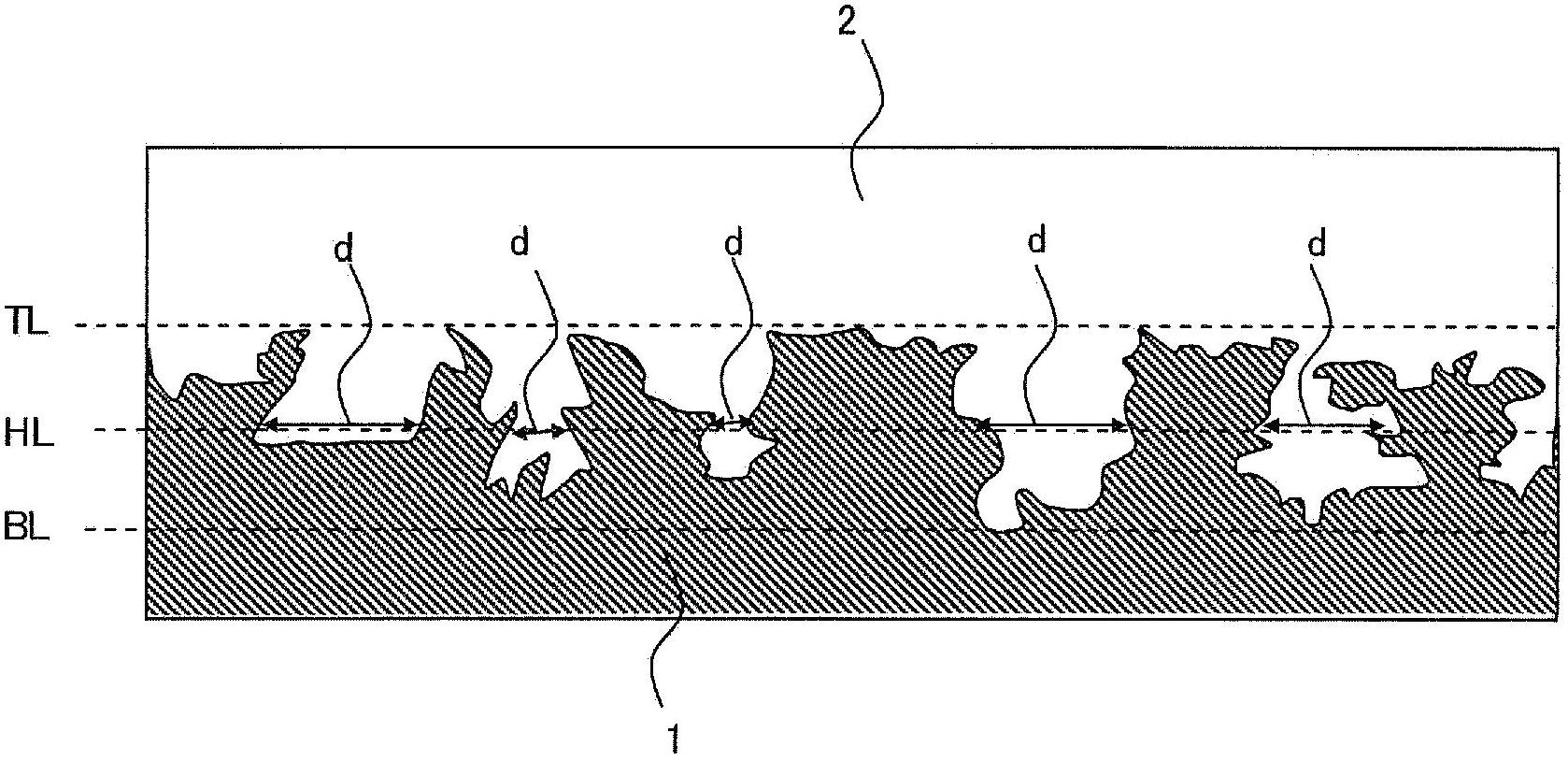

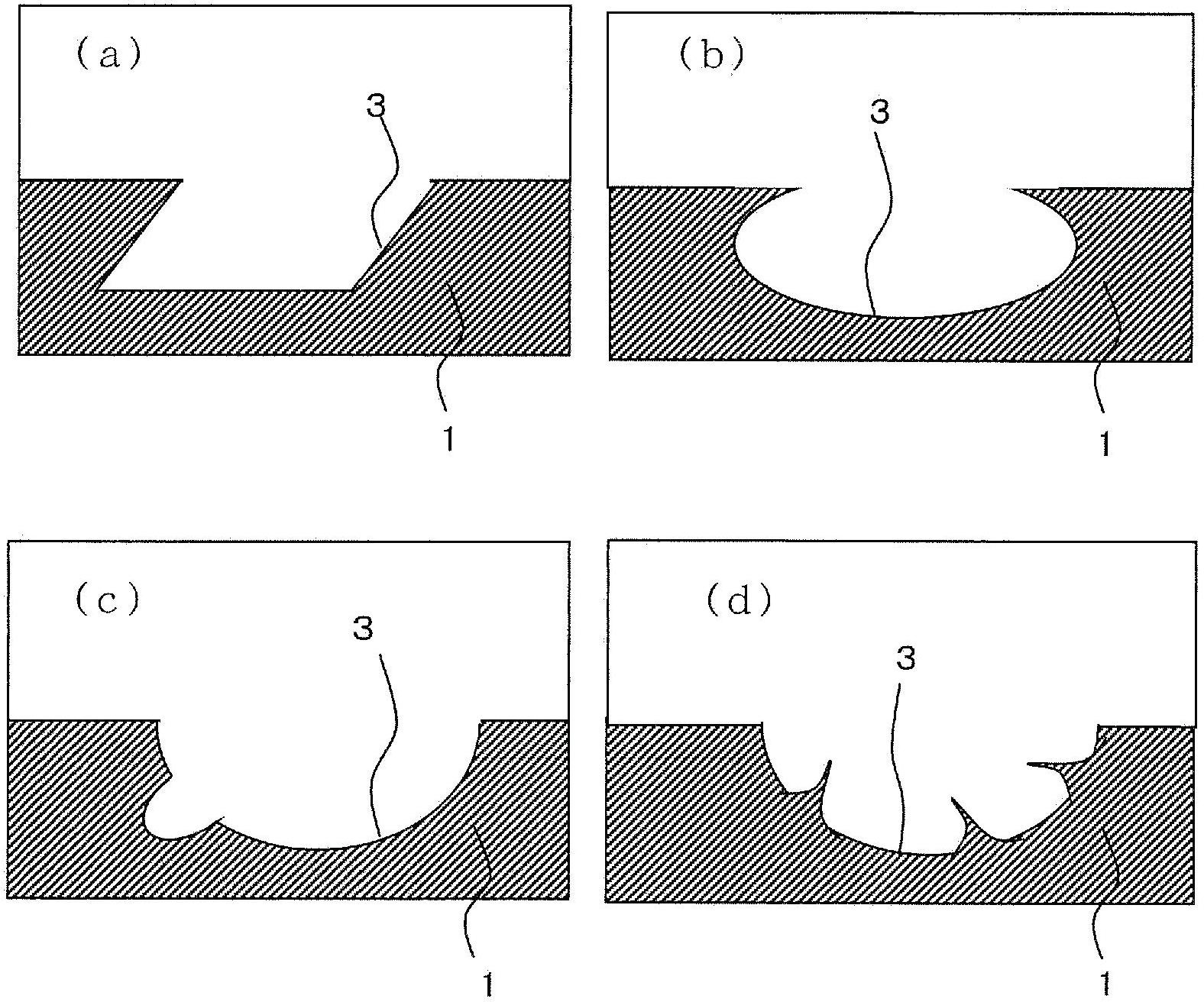

[0085] Next, the above-mentioned pretreated aluminum sheet is subjected to etching treatment, that is, adding 54 g / L of aluminum chloride hexahydrate (AlCl 3 ·6H 2 O) As a water-soluble inorganic halide, it is prepared into an etching solution (chloride ion concentration: 48 g / L), immersed in the etching solution at 66° C. for 4 m...

Embodiment 2~5

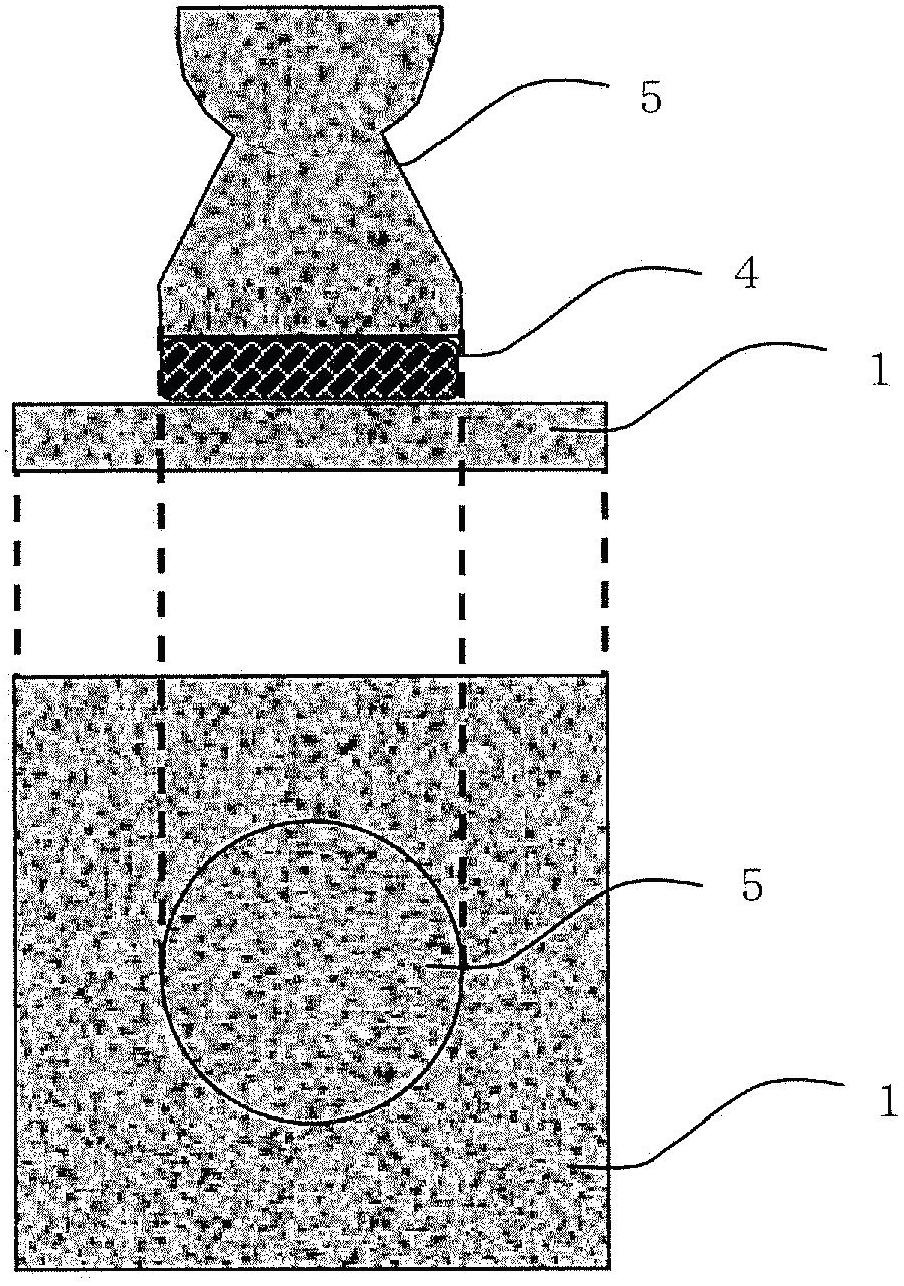

[0118] In addition to using the treatment liquid shown in the following Table 1, the aluminum test piece (aluminum molded body) and the test body were used as a circular forging die under the treatment conditions shown in the following Table 1 instead of the 80°C, 20-minute heating in Example 1. The water and treatment of water immersion were used as the aluminum film formation treatment, and the test samples for evaluation (aluminum-adhesive-aluminum test piece, aluminum-resin-aluminum test piece, and aluminum-resin test piece) were produced in the same manner as in Example 1. , In addition, in the same manner as in Example 1 above, a weather resistance test (salt spray test), a pull-off adhesion measurement test, and a resin-aluminum-resin lamination portion observation and evaluation were implemented.

[0119] The results are shown in Table 2 together with the results of Example 1.

[0120] [Table 1]

[0121]

[0122] (Note) Silane coupling agent: β-(3,4-epoxycyclohexyl...

Embodiment 6

[0125] Except having used JIS A5052-H34 as the aluminum alloy plate for producing the aluminum sheet, in the same manner as in the above-mentioned Example 1, a circular dolly was produced simultaneously with the production of the aluminum test piece (aluminum molded body). Next, test samples for evaluation (aluminum-adhesive-aluminum test piece, aluminum-resin-aluminum test piece, and aluminum-resin test piece) were produced in the same manner as in Example 1 above. In addition, as in Example 1, A weather resistance test (salt spray test), a pull-off adhesion measurement test, and an observation evaluation of a laminated portion of resin-aluminum-resin were implemented.

[0126] The results are shown in Table 2 together with the results of Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com