Extraction method and purpose of jute fiber extracts with bacteriostatic activity

A jute fiber and extraction method technology, applied in the directions of botanical equipment and methods, fiber treatment, application, etc., can solve the problems of low bacteriostatic activity, easy loss of activity, and low raw material yield of extracts, and achieves inhibition of Escherichia coli activity, Improved extraction efficiency and large surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

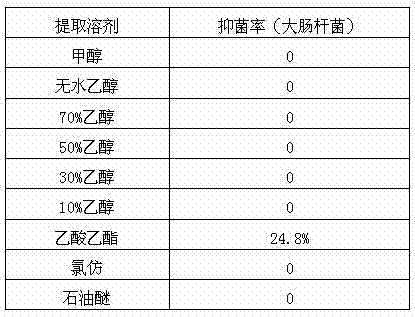

[0022] Example 1 Jute fiber ethyl acetate reflux extraction

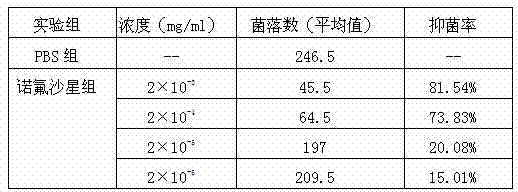

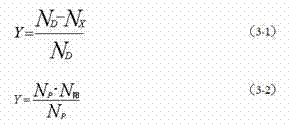

[0023] Take 1kg of dry jute fiber, cut into 1cm, place in 20L ethyl acetate (boiling point 77°C), reflux for extraction for 1.5h, filter with suction, then wash the filter residue and bottle wall with 5L extraction solvent for 5 times, combine the filtrate, the filtrate Ethyl acetate was recovered under reduced pressure to obtain 1.95 g of extract.

[0024] Antibacterial activity experiment proves, the extract of the present embodiment is to Escherichia coli (total bacteria number 10 4 CFU) MIC is 0.625mg / ml, against Staphylococcus aureus (total bacterial count 1 / 2×10 4 CFU) of the MIC is 9.175mg / ml; 30 ℃, the solubility of the extract in water 12mg / 100g water.

Embodiment 2

[0025] Example 2 Jute fiber n-butyl acetate reflux extraction

[0026] Take 1 kg of dried jute fiber, crush it through a 20-mesh sieve, place it in 35L n-butyl acetate (boiling point 126°C), extract it under reflux for 2 hours, filter it with suction, wash the filter residue and bottle wall with 5L extraction solvent for 5 times, combine the filtrate, The filtrate recovered n-butyl acetate under reduced pressure to obtain 1.1 g of extract.

[0027] Antibacterial activity experiment proves, the extract of the present embodiment is to Escherichia coli (total bacteria number 10 4 CFU) MIC is 3.5mg / ml, against Staphylococcus aureus (total bacterial count 1 / 2×10 4CFU) of the MIC is 11.15mg / ml; 30 ℃, the solubility of the extract in water 10mg / 100g water.

Embodiment 3

[0028] Example 3 Jute fiber n-propyl acetate reflux extraction

[0029] Take 1 kg of dried jute fiber, crush it through a 10-mesh sieve, place it in 25L n-propyl acetate (boiling point 101.6°C), reflux for extraction for 2 hours, filter with suction, then wash the filter residue and bottle wall with 5L extraction solvent for 5 times, combine the filtrate, The filtrate recovered n-propyl acetate under reduced pressure to obtain 1.3 g of extract.

[0030] Antibacterial activity experiment proves, the extract of the present embodiment is to Escherichia coli (total bacteria number 10 4 CFU) MIC is 1.15mg / ml, against Staphylococcus aureus (total bacterial count 1 / 2×10 4 CFU) of MIC is 10.2mg / ml; 30 ℃, the solubility of the extract in water is 10.5mg / 100g water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com