Organic-inorganic nano composite resin and preparation method thereof

A composite resin and inorganic nanotechnology, which is applied in dental preparations, pharmaceutical formulations, dental prostheses, etc., can solve the problems of being unable to be put into the market, reducing the mechanical properties of materials, and poor storage stability, etc., to achieve good micro-leakage and biological Compatibility, low cost, effect of reducing polymerization shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Embodiment 1: The composite resin in this embodiment is composed of resin matrix (mass ratio 14.8~39.8%) and inorganic filler (mass ratio 60~85%), and a functional monomer—organic- Inorganic polyfunctional reactive nano-monomer POSS, the mass ratio is 0.2~15%.

[0018] In this embodiment:

[0019] 1. The polymerizable monomer system includes resin monomer / diluent, and its mass ratio is 40~70:30~60, for example, the mass ratio is 50 / 50 or 70 / 30;

[0020] 2. The initiator system (for the initial polymerization reaction) includes photoinitiator / organic amine activator (mass ratio 1:1), and the mass ratio is 0.2~0.8% of the resin matrix;

[0021] 3. The mass ratio of the photoinitiator in the resin matrix is 0.2~0.8%. The photoinitiator includes camphorquinone (CQ), benzil, 4, 4'-dimethoxybenzil, α-diketone and Phenylpropane, Trimethylbenzoyl, Diphenylphosphine Oxide, 2,4-Dimethicone, and photosensitive pigments (tetrabromofluorescein / amine, riboflavin, floral pigment);...

specific Embodiment approach 2

[0028] Embodiment 2: The composite resin in this embodiment includes a resin matrix and an inorganic filler, which are mixed in a mass ratio of 40%:60%. The mass ratio of functional monomer POSS-methacrylate is 0.2~15%, which partially replaces the resin matrix, and is added to the composite resin and mixed evenly.

[0029] The specific steps are:

[0030] 1. The resin monomer Bis-GMA is placed in a constant temperature drying oven at 70°C and left to stand for 40 minutes to greatly reduce the viscosity and meet the mixing needs;

[0031] 2. Put the resin monomer Bis-GMA and the diluent TEGDMA into a light-proof container with a mass fraction of 40% and 60% respectively, and stir magnetically at room temperature for 30 minutes;

[0032] 3. Add the functional monomer—organic-inorganic multifunctional reactive nanomonomer multifunctional methacrylic-based multifaceted oligomeric oligomeric silsesquioxane POSS-methacrylate into the container, partially replace the resin matrix, ...

specific Embodiment approach 3

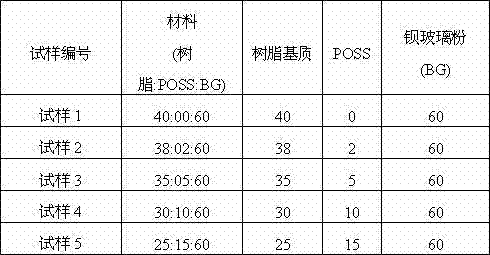

[0037] Embodiment 3: The composite resin in this embodiment includes a resin matrix and an inorganic filler, which are mixed in a mass ratio of 40%:60%. The resin matrix includes a resin monomer system and an initiator system, wherein the resin monomer system Bis-GMA / TEGDMA is mixed at a mass ratio of 49.5%:49.5%, and then the initiator system CQ / DMAEMA with a mass ratio of 0.5%:0.5% is added. The inorganic filler is barium glass powder (average diameter 0.8μm) with silanized surface. The functional monomer POSS-methacrylate is 0%, 2%, 5%, 10% and 15% by weight, respectively, and partially replaces the resin matrix, and is added to the composite resin and mixed evenly.

[0038] The specific ratio of nanocomposite resin is shown in Table 1.

[0039] Table 1 Components of dental nanocomposite resins (wt%)

[0040]

[0041] According to the relevant regulations in ISO3521, the density ρ of the material before and after light curing is measured by the pycnometer method, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Flexural strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com