Liquid crystal polymer and preparation method thereof, and liquid crystal polymer composite materials

A liquid crystal polymer and composite material technology, applied in liquid crystal materials, chemical instruments and methods, etc., can solve the problems of insufficient thermal deformation temperature, insufficient bonding line, poor recyclability, etc., to improve the comprehensive mechanical properties and processing temperature. The effect of widening the range and easy control of the reaction end point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

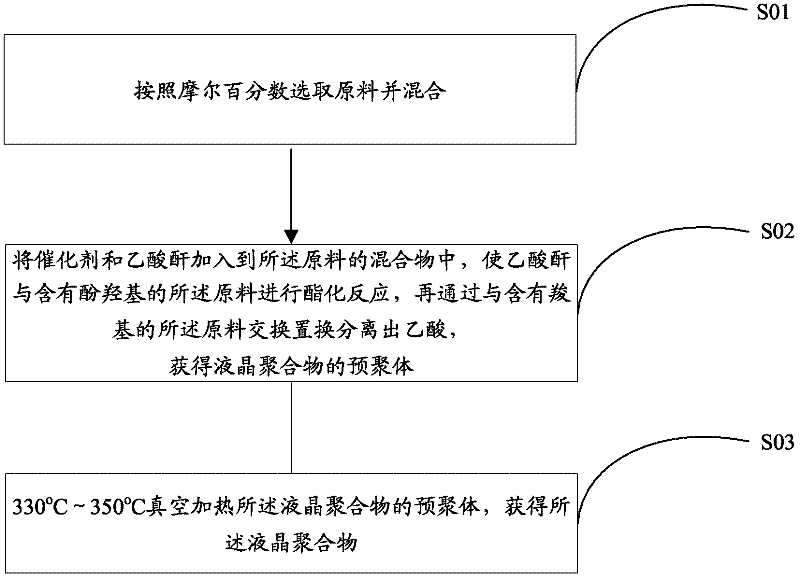

[0027] The embodiment of the present invention additionally provides a method for preparing the above-mentioned liquid crystal polymer, which includes the following steps:

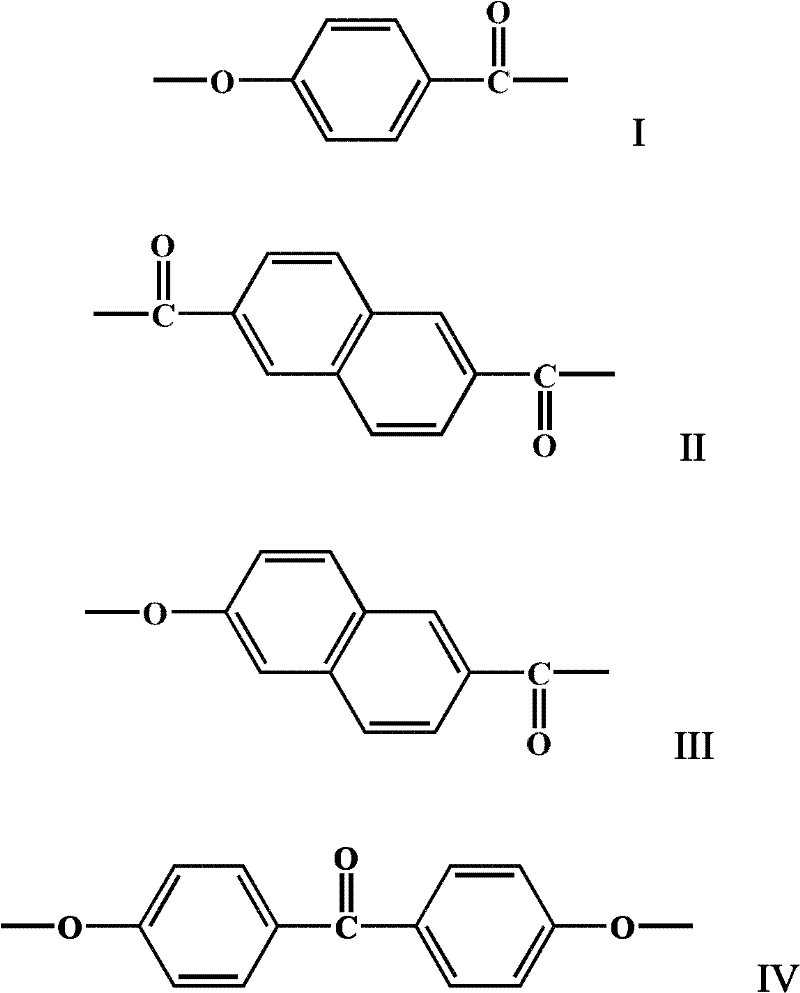

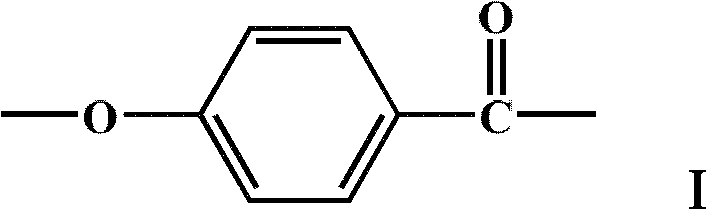

[0028] S01: Select and mix raw materials according to molar percentages, the raw materials include 20% to 70% of p-hydroxybenzoic acid, 5% to 40% of 2,6-naphthalene dicarboxylic acid, and 5% to 20% of 6-hydroxy-2-naphthoic acid and 4,4-dihydroxybenzophenone 5% to 40%;

[0029] S02: Add catalyst and acetic anhydride to the mixture of raw materials, make acetic anhydride esterify with the raw materials containing phenolic hydroxyl groups, and then separate acetic acid by exchanging and displacing with the raw materials containing carboxyl groups to obtain liquid crystal polymerization Prepolymers of substances;

[0030] S03: heating the prepolymer of the liquid crystal polymer in vacuum at 330° C. to 350° C. to obtain the liquid crystal polymer.

[0031] In step S01, all the raw materials can be prepared b...

Embodiment 1

[0042]According to the molar ratio of 40:20:10:20:5:5, p-hydroxybenzoic acid (HBA), 2,6-naphthalene dicarboxylic acid (NDA), 6-hydroxy-2-naphthoic acid (HNA), 4,4 - Dihydroxybenzophenone (HBQ), terephthalic acid (TA) and biphenol (BHQ), and the corresponding amount of acetic anhydride and 0.05 molar parts of catalyst potassium acetate are added to the Hastelloy with reflux water separation device The reactor was replaced three times with 99.999% nitrogen, and the temperature was raised to 180° C. to completely reflux the solvent into the reactor. After 45 minutes, the solvent was separated, and a total of 30% of the solvent amount was separated. Raise the temperature to 330°C, keep the pressure at 1 atmosphere, continue to raise the temperature to 350°C, and start the vacuum device at the same time to reduce the pressure to below 100Pa, until the torque of the stirring blade of the reactor reaches the maximum and the reaction ends to obtain a liquid crystal polymer.

Embodiment 2

[0044] According to the molar ratio of 50:15:10:15:5:5, p-hydroxybenzoic acid (HBA), 2,6-naphthalene dicarboxylic acid (NDA), 6-hydroxy-2-naphthoic acid (HNA), 4,4 -Dihydroxybenzophenone (HBQ), terephthalic acid (TA) and biphenol (BHQ), and the corresponding amount of acetic anhydride and 0.05 mole parts of catalyst zinc acetate are added to the Hastelloy with reflux water separation device The reactor was replaced three times with 99.999% nitrogen, and the temperature was raised to 180° C. to completely reflux the solvent into the reactor. After 45 minutes, the solvent was separated, and a total of 30% of the solvent amount was separated. Raise the temperature to 330°C, keep the pressure at 1 atmosphere, continue to raise the temperature to 350°C, and start the vacuum device at the same time to reduce the pressure to below 100Pa, until the torque of the stirring blade of the reactor reaches the maximum and the reaction ends to obtain a liquid crystal polymer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com