Realization method for lead bonding thick aluminum wire

A realization method and wire bonding technology, applied in the manufacture of electrical components, electrical solid devices, semiconductor/solid devices, etc., can solve problems such as product reliability discount, cost increase, complex conditions, etc., and achieve simplification of welding equipment and production process Simplification and great electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The invention will be described in further detail below with reference to the embodiments of the accompanying drawings.

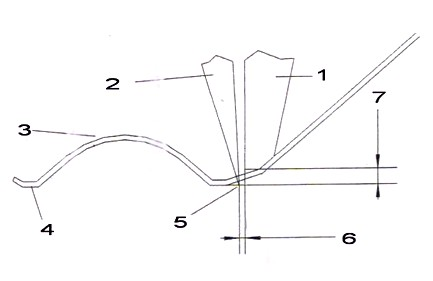

[0048] according to figure 1 When welding, adopt the method for realizing thick aluminum wire lead bonding of the present invention, and its operating conditions are as follows:

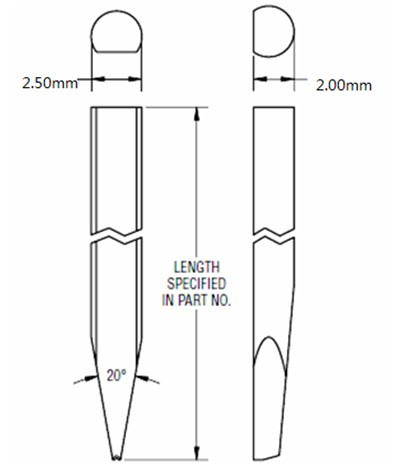

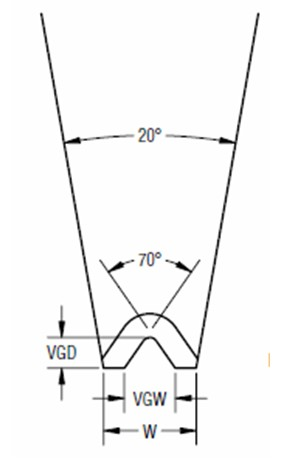

[0049] (1) Selection of rivets

[0050] Due to the good ductility of aluminum wire, during the operation of the production line, it is easy to cause de-soldering when pulling the wire, and continuous operation cannot be performed. It is necessary to design a riving knife that matches the specifications of the thick aluminum wire diameter. , so as to ensure the smooth operation of the production line. There are several parts of the rivet that need to be modified, including T size, BL size, ER&BF size, H size, W size, VGW size; in addition, the choice of rivet material and surface finish ensures that the rivet has enough strength to complete The welding process is not easy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com