Composite roll having uniform roll surface hardness and made of high-speed steel containing boron and method for manufacturing composite roll

A composite roll with uniform hardness technology, which is applied in the field of roll manufacturing, can solve the problems of long cycle time and low efficiency, and achieve the effects of improving strength and toughness, fast cooling, and preventing fracture accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

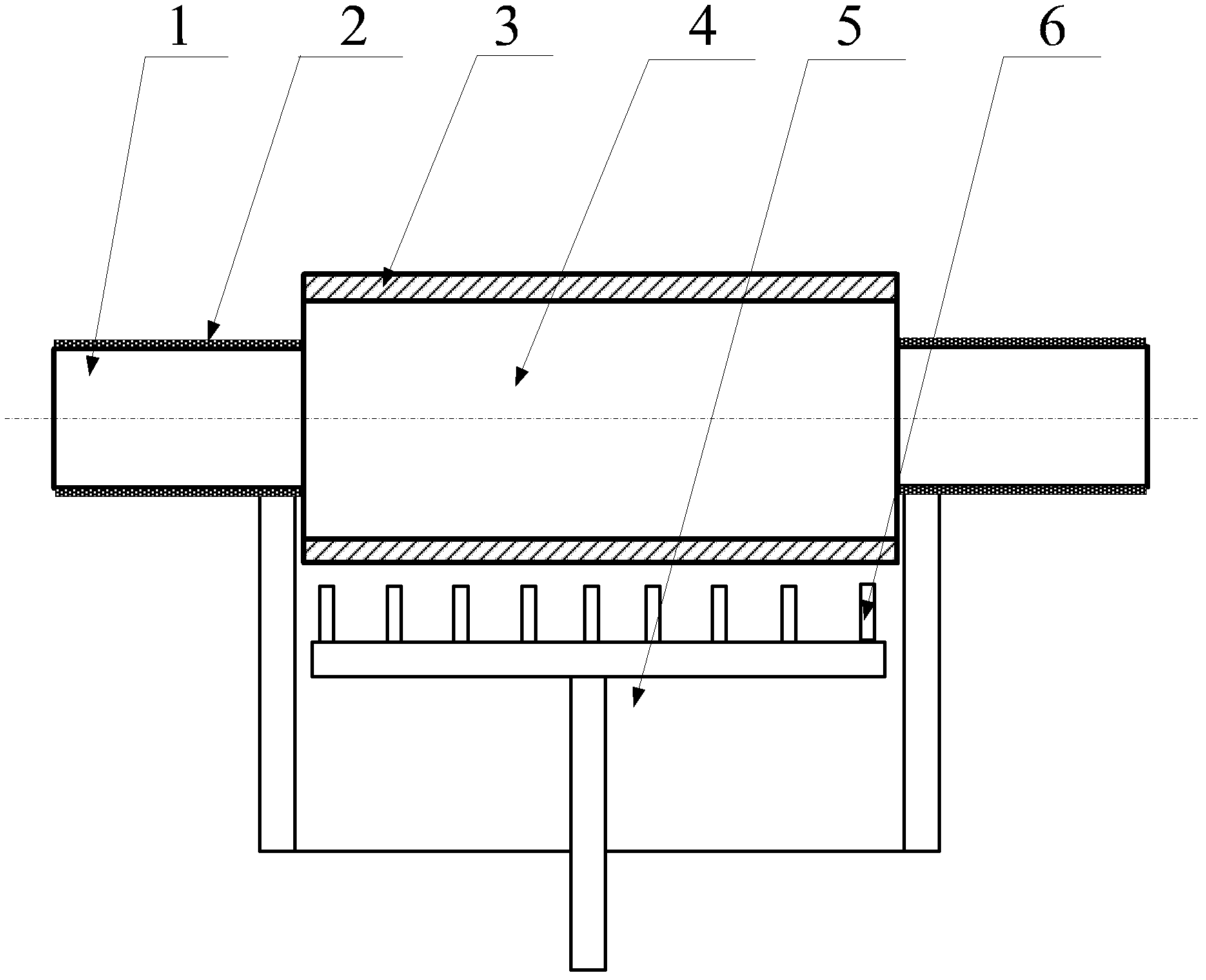

[0033] The roll body (3) is made of boron-containing high-speed steel, the roll neck (1) and the roll center (4) are made of ductile iron, and is cast into a boron-containing high-speed steel composite roll through centrifugal composite casting. Heating in the furnace to 1080°C, after 4 hours of heat preservation, place it in the cooling control device (5), and make the roll rotate at a speed of 20rpm during the cooling process, and at the same time, coat the heat insulating material (2) on the roll neck (1) surface , and the roll neck (1) is placed outside the cooling control device (5). Insulation material (2) is CaO / SiO with a thermal conductivity of 0.043 (w / m.k) 2 , and its thickness is 2mm. Using mist and gas cooler (6), first press the spray quenching process parameter 1 (P 空气 =0.15MPa, P 水 = 0.30MPa, Q 水 =1.65m 3 / h) spray cooling for 6 minutes, then reduce the cooling rate, and use the spray quenching process parameter 2 (P 空气 =0.55MPa, P 水 =0.05MPa, Q 水 =0.35...

Embodiment 2

[0035] The roll body (3) is made of boron-containing high-speed steel, the roll neck (1) and the roll center (4) are made of ductile iron, and is cast into a boron-containing high-speed steel composite roll through centrifugal composite casting. Heating in the furnace to 1060°C, after 6 hours of heat preservation, place it in the cooling control device (5), and make the roll rotate at a speed of 15rpm during the cooling process, and at the same time coat the heat insulating material (2) on the surface of the roll neck (1) , and the roll neck (1) is placed outside the cooling control device (5). The heat insulating material (2) is an asbestos cloth with a thermal conductivity of 0.069 (w / m.k), and its thickness is 4mm. Using mist and gas cooler (6), first press the spray quenching process parameter 1 (P 空气 =0.12MPa, P 水 =0.35MPa, Q 水 =1.80m 3 / h) spray cooling for 5 minutes, then reduce the cooling rate, and switch to press spray quenching process parameter 2 (P 空气 =0.45MP...

Embodiment 3

[0037] The roll body (3) is made of boron-containing high-speed steel, the roll neck (1) and the roll center (4) are made of ductile iron, and is cast into a boron-containing high-speed steel composite roll through centrifugal composite casting. Heat the furnace to 1070°C, place it in the cooling device (5) after being kept warm for 5 hours, and make the roll rotate at a speed of 18rpm during the cooling process, and at the same time coat the heat insulating material (2) on the surface of the roll neck (1) , and the roll neck (1) is placed outside the cooling control device (5). Insulation material (2) is CaO / SiO with a thermal conductivity of 0.043 (w / m.k) 2 , and its thickness is 2mm. Using mist and gas cooler (6), first press the spray quenching process parameter 1 (P 空气 =0.13MPa, P 水 =0.32MPa, Q 水 =1.75m 3 / h) spray cooling for 6 minutes, then reduce the cooling rate, and use the spray quenching process parameter 2 (P 空气 =0.50MPa, P 水 =0.067MPa, Q 水 =0.40m 3 / h) C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com