Operation technology for electric furnace converter

An operation process and electric furnace technology, applied in the field of metallurgy, can solve the problems of serious production splash, short electric furnace smelting time, difficult dephosphorization, etc., and achieve the effects of optimizing the masonry process, reducing residual harmful elements and reducing splashing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

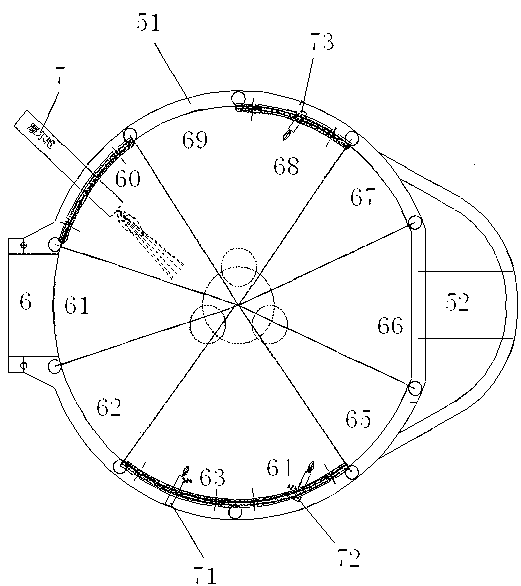

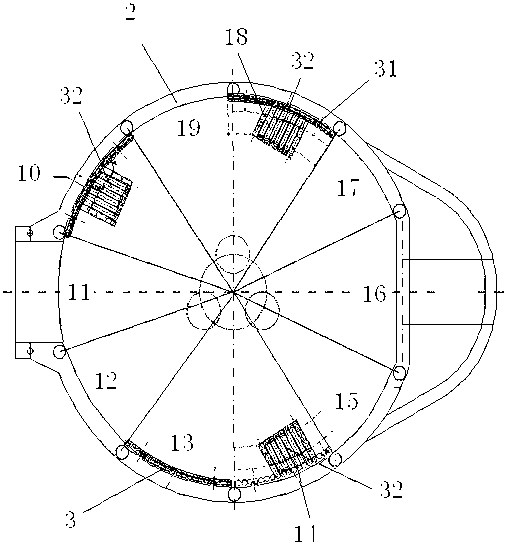

[0027] A kind of operation technique of electric furnace conversion is characterized in that the technique comprises the following steps:

[0028] 1) The furnace material structure of 85-95% molten iron and 5-15% steel scrap is adopted. After the cover of the electric furnace is opened, steel scrap is added through the material basket at one time;

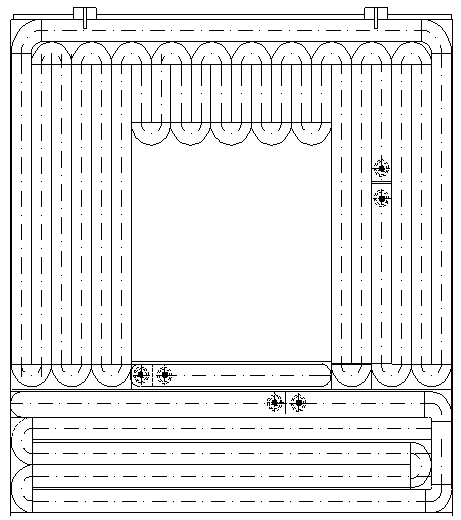

[0029] 2) Use the iron mixing device to continuously add molten iron into the electric furnace at a speed of 2.0-4.0 tons / min, and at the same time inject oxygen flow into the furnace through three furnace wall Prax carbon oxygen lances installed on the furnace wall, and Adjust the oxygen supply intensity according to the blowing conditions in the furnace to ensure that the carbon content in the furnace is stable at 0.40-0.80%;

[0030] 3) While blowing oxygen, add lime, returned ore, and limestone to the electric furnace to make slag and adjust the temperature of molten steel in the furnace. During the blowing process, the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com