Extraction and preparation method by comprehensively utilizing liquorice

A technology of licorice and glycyrrhizic acid, which is applied in the field of preparation of isoliquiritigenin and glycyrrhizinic acid, can solve the problems of toxic organic solvent isoliquiritigenin product quality, damage to glycyrrhizic acid components, increase production costs, etc., to save traditional Chinese medicine resources and improve The effect of comprehensive utilization and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

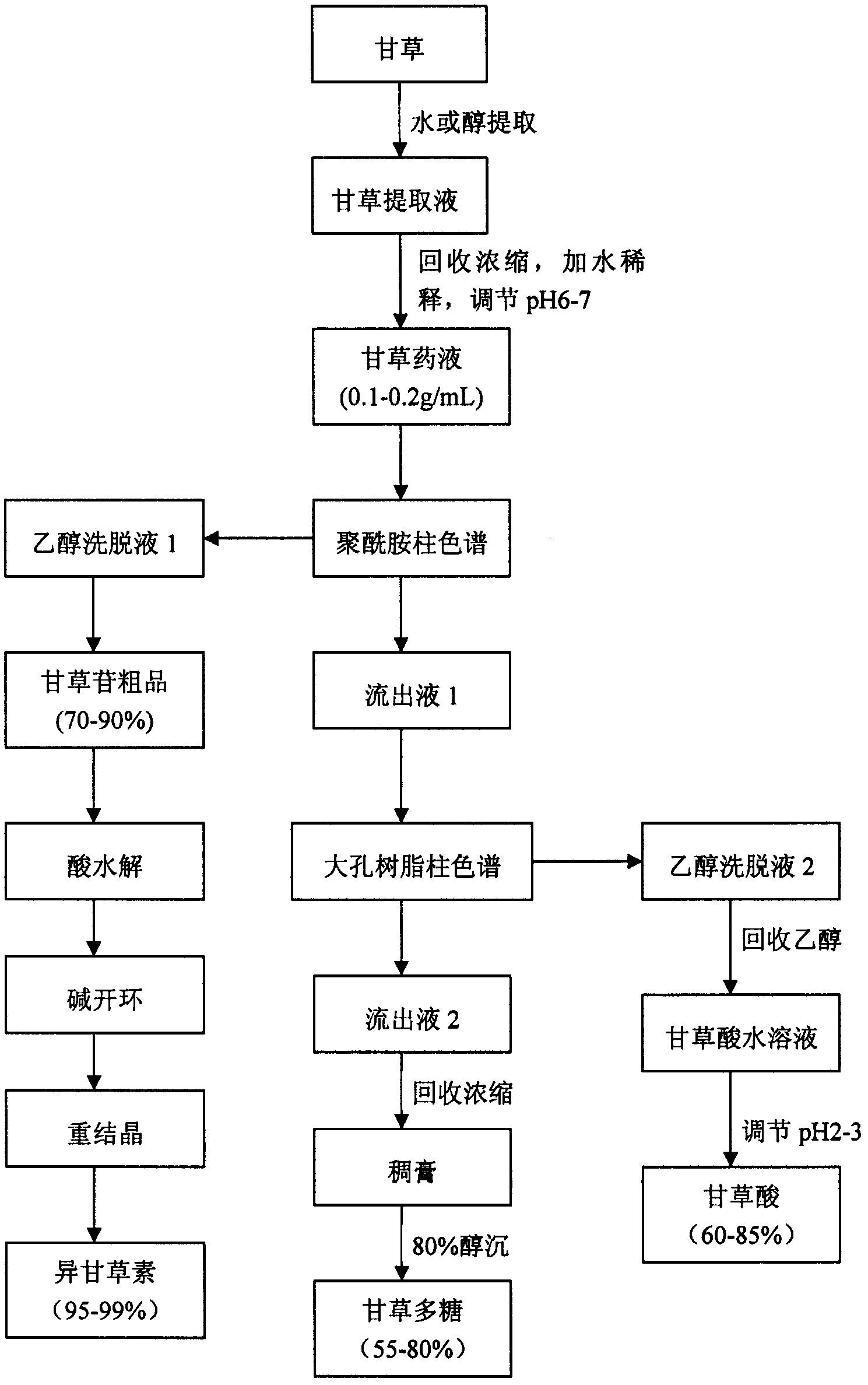

Method used

Image

Examples

Embodiment 1

[0068] Take 5kg of licorice, add water to decoct twice, add water to 8 times the weight of the medicinal material for the first time, decoct for 2 hours, add water for the second time to 6 times the weight of the medicinal material, decoct for 1 hour, combine the decoction, filter, and filtrate Concentrate under reduced pressure at 0.07MPa and 80°C to 2.5L (the amount of crude drug is 0.2g / mL), add ammonia to adjust the pH to 6.0, and pass through 80-100 mesh polyamide (dry weight: 2.5kg) chromatographic column and AB-8 Macroporous resin (dry weight is 2.5kg) chromatographic column;

[0069] Preparation of licorice polysaccharide: collect the effluent, concentrate to 65°C when the relative density is 1.10, add 95% (v / v) ethanol to make the alcohol content reach 80% (v / v), stir, let stand for 12 hours, filter and dry , to obtain licorice polysaccharide 206g, the content is 56.2% (anthrone sulfate colorimetric method);

[0070] Preparation of isoliquiritigenin: The polyamide ch...

Embodiment 2

[0073] Take 5kg of licorice, reflux extraction twice, add 8 times the amount of 50% ethanol for the first time, reflux extraction for 2 hours, add 6 times the amount of 50% ethanol for the second time, reflux extraction for 2 hours, combine the extracts, filter, and the filtrate is at 0.12MPa , Recover ethanol under reduced pressure at 60°C, add water to 2.5L (crude drug amount 0.2g / mL), add 10% sodium hydroxide solution to adjust pH to 7.0, and pass through 80-100 mesh polyamide (dry weight: 10kg) chromatography Column and AB-8 macroporous resin (dry weight is 10kg) chromatographic column;

[0074] Preparation of licorice polysaccharide: collect the effluent, concentrate to 65°C when the relative density is 1.15, add 95% (v / v) ethanol to make the alcohol content reach 80% (v / v), stir, let stand for 24 hours, filter and dry , to obtain 91g of Glycyrrhiza polysaccharide, the content of which is 63.8% (anthrone sulfate colorimetric method);

[0075] Preparation of isoliquiritig...

Embodiment 3

[0078] Take 5kg of licorice, add water to decoct twice, add water to 8 times the weight of the medicinal material for the first time, decoct for 2 hours, add water for the second time to 6 times the weight of the medicinal material, decoct for 1 hour, combine the decoction, filter, and filtrate Concentrate under reduced pressure at 0.10MPa and 70°C to 5L (the amount of crude drug is 0.1g / mL), add ammonia to adjust the pH to 6.0, and pass through 80-100 mesh polyamide (dry weight: 5kg) chromatographic column and AB-8 macroporous Resin (dry weight is 5kg) chromatographic column;

[0079]Preparation of licorice polysaccharide: collect the effluent, concentrate to 65°C when the relative density is 1.15, add 95% (v / v) ethanol to make the alcohol content reach 80% (v / v), stir, let stand for 36 hours, filter and dry , to obtain licorice polysaccharide 183g, the content is 78.6% (anthrone sulfate colorimetric method);

[0080] Preparation of isoliquiritigenin: The polyamide chromatog...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com