Pulsating heat pipe heat-expanding plate and manufacturing method thereof

A technology of pulsating heat pipes and manufacturing methods, applied in indirect heat exchangers, lighting and heating equipment, cooling/ventilation/heating transformation, etc., can solve problems affecting system reliability, component performance degradation, and inability to work stably, and achieve high The effect of heat transfer, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

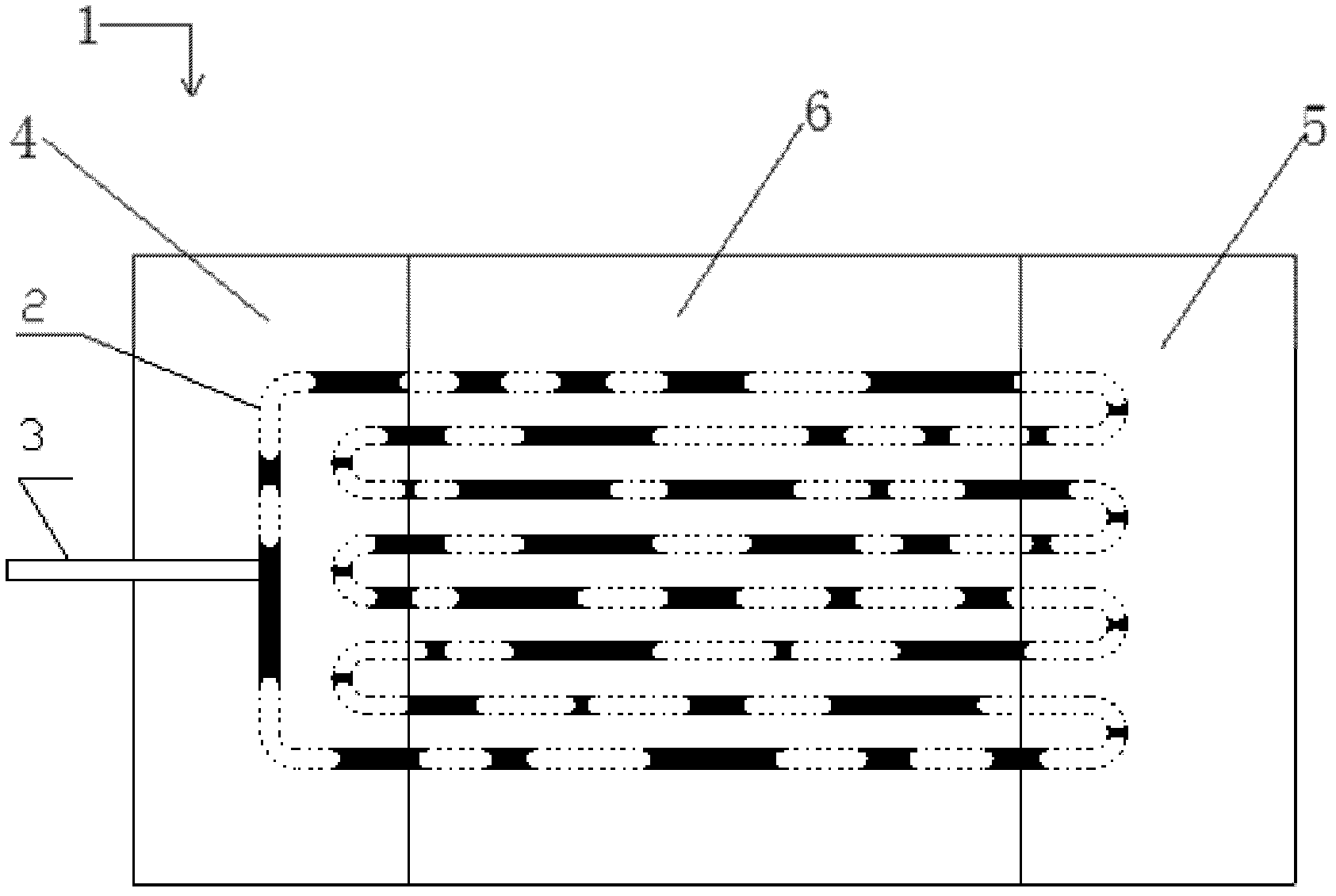

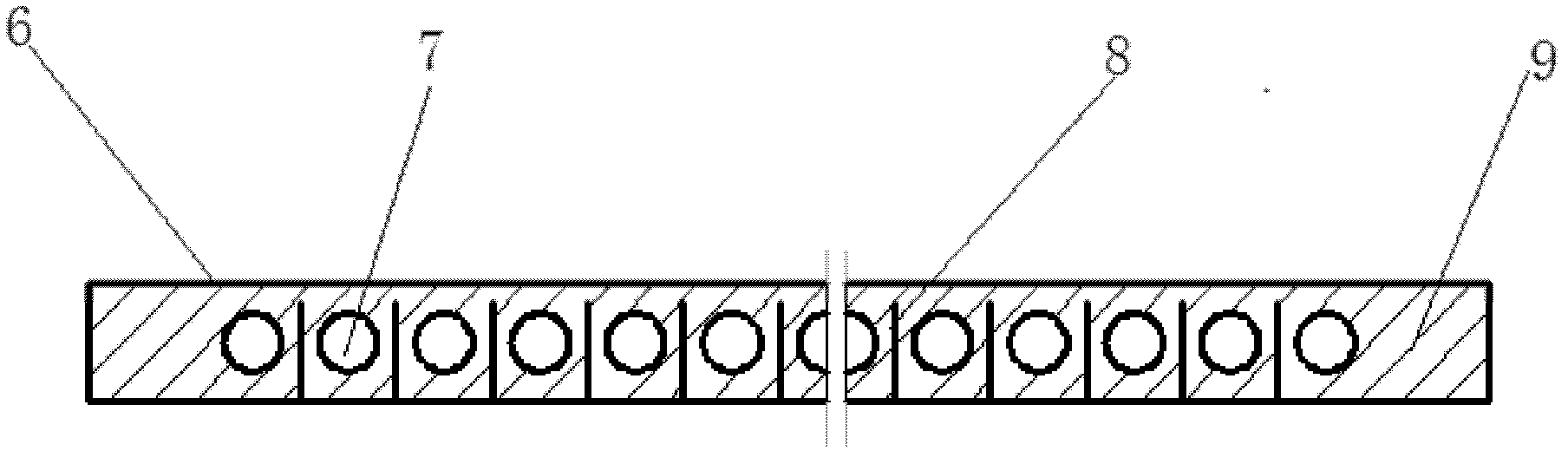

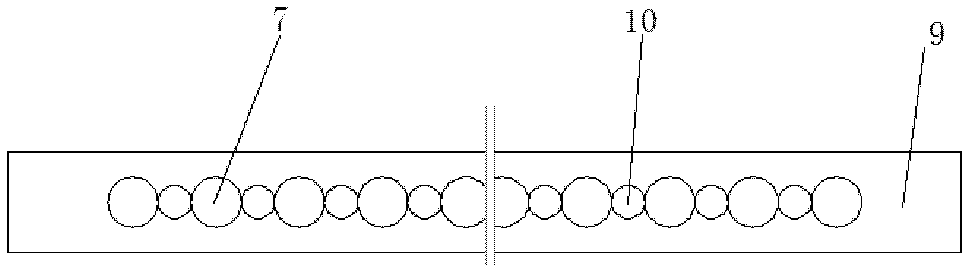

[0035] Such as Figures 1 to 6 As shown, the pulsating heat pipe expansion plate 1 includes a base plate 9, a front plug 11, a rear plug 12, and cover plates 4, 5, and 6, and the designed size of the heat expansion plate is 60×260×3mm 3 , the pulsating heat pipe heat expansion plate is produced in the following order: 1) Select a thicker plate, such as 8mm or 5mm, as the substrate 9, the substrate 9 is an oxygen-free copper plate or an L2 aluminum plate, and the substrate 9 is processed by wire cutting. A plurality of parallel capillary channels 7, then cut a slit 8 on the substrate between adjacent two capillary channels 7, but do not cut through, the depth of the slit 8 does not exceed the thickness of the substrate, the cross section of the heat expansion plate is as follows figure 2 As shown; 2) process several cylindrical protrusions 10 with a diameter of 1mm on the two ends of the substrate 9 connected to the front and rear plugs 11, 12, such as image 3 , 4 As shown,...

Embodiment 2

[0043] Such as figure 1 , 2 , 9, and 10, the size of the designed heat expansion plate is 60×260×3mm 3 , the pulsating heat pipe heat expansion plate 1 is produced in the following order: 1) select a relatively thick plate (such as 8mm or 5mm) as the base plate 9, the base plate is an oxygen-free copper plate or an L2 aluminum plate, and adopts the mode of wire cutting to process on this base plate. A plurality of parallel capillary channels 7, then cut a slit 8 on the substrate 9 between adjacent two capillary channels 7, but do not cut through, the depth of the slit 8 does not exceed the thickness of the substrate 9, and the heat expansion plate 1 cross section as figure 2 As shown; 2) The substrate 9 is gradually thinned to the target size, and then the upper cover plate 6 is welded on the side of the substrate 9 with the capillary channel 7 and the slit 8; 3) On the two ends of the substrate 9, respectively weld the strips There are front and rear plugs 11', 12' with e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com