Preparation method of Ag/Ag (I)-TiO2 nanocrystalline visual light photochemical catalyst

A photocatalyst and nanocrystal technology, which is applied in the preparation field of Ag/Ag(I)-TiO2 nanocrystal visible light photocatalyst, can solve the problems of short photogenerated carrier lifetime, low photocatalytic activity and low quantum yield , to achieve high visible light photocatalytic performance, simple operation, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

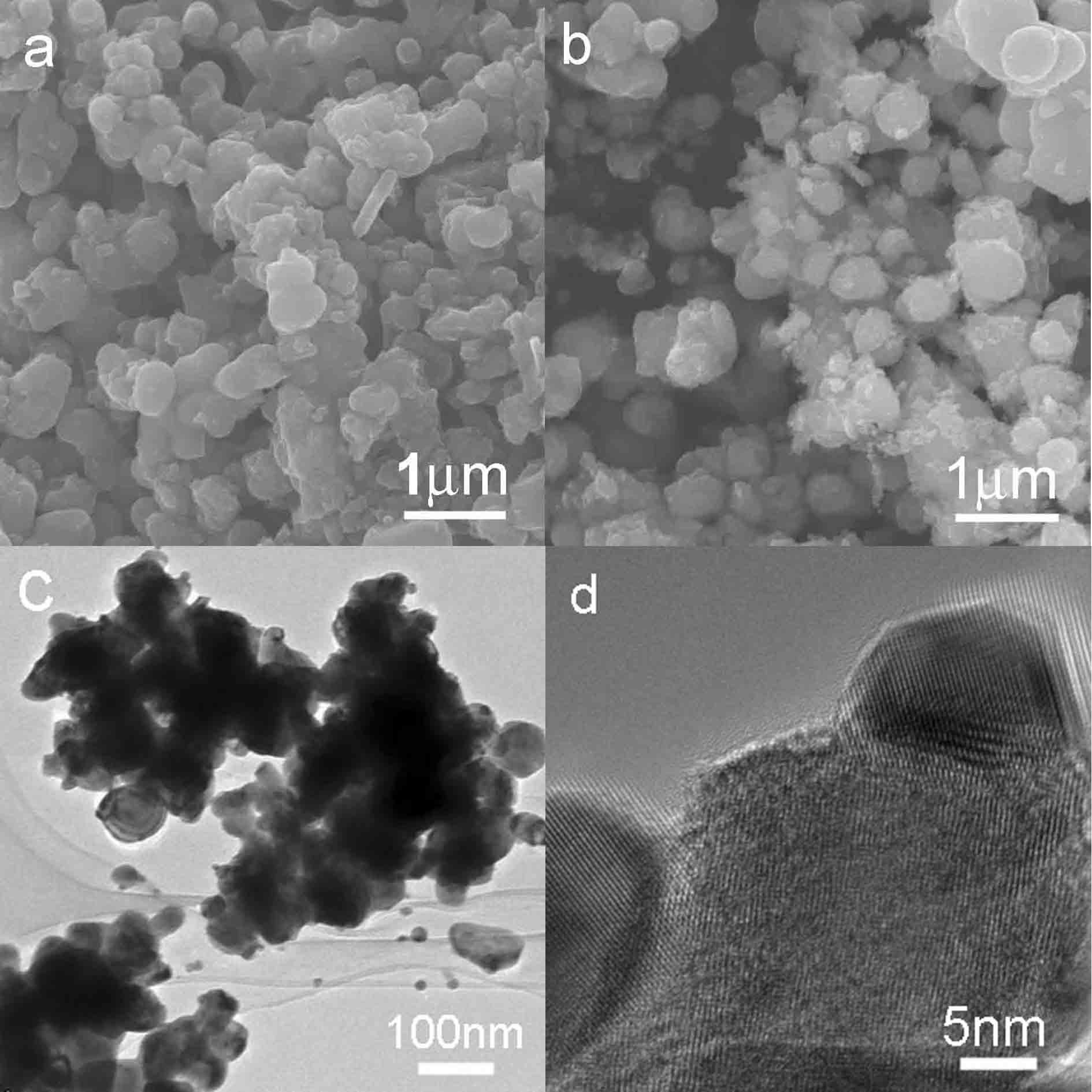

Image

Examples

Embodiment 1

[0027] Ag / Ag(I)-TiO 2 The preparation process of nanocrystalline visible light photocatalyst is as follows: 1) TiO 2 Preparation of nanocrystals: 14 mL of butyl titanate was added to 1000 mL of deionized water under stirring at room temperature, stirred thoroughly for 2 h, left to age at 30 °C for 12 h, separated by filtration and separated with deionized water and anhydrous Washed with ethanol three times respectively, the obtained amorphous TiO 2 The powder was dried at 80°C for 6 h; then the dried TiO 2 The powder was crystallized at 500°C for 2 h to obtain anatase phase TiO 2 Nanocrystalline, with an average grain size of 30 nm and a specific surface area of 55.6 m 2 g -1 ; 2) Dissolve silver nitrate in deionized water to form a uniform solution, in which the molar concentration of silver nitrate is 0.1 mol L -1 ; 3) Add 1 g TiO 2 Nanocrystals dispersed to 9.3 mL 0.1 mol L -1 in silver nitrate solution, fully stirred for 2 h, dried at 80°C, and heat-treated the p...

Embodiment 2

[0036] In order to examine the effect of silver nitrate concentration on Ag / Ag(I)-TiO 2The effect of nanocrystalline visible light photocatalytic activity, in addition to the different concentration of silver nitrate, other reaction conditions such as: anatase phase TiO 2 Nanocrystalline raw material (1g, grain size is 10-50 nm, specific surface area is 55.6 m 2 g -1 ), the volume of silver nitrate solution (9.3 mL), stirring time (2 h), drying temperature (80 °C), final heat treatment temperature (450 °C) and heat treatment time (1 h) were all the same as in Example 1. The results showed that when the silver nitrate concentration was 0.01, 0.05, 0.2 and 0.5 mol L -1 , the prepared Ag / Ag(I)-TiO 2 The degradation rates of methyl orange by nanocrystalline photocatalysts were 0.04, 0.095, 0.98 and 0.06 min, respectively -1 . The reason may be that when the Ag content is less, the TiO 2 The content of Ag(I) ions in the phase is also less, resulting in a decrease in the abso...

Embodiment 3

[0039] In order to examine the effect of stirring time on Ag / Ag(I)-TiO 2 The effect of visible light photocatalytic activity of nanocrystals, in addition to different stirring time, other reaction conditions such as: anatase phase TiO 2 Nanocrystalline raw material (1g, grain size is 10-50 nm, specific surface area is 55.6 m 2 g -1 ), the volume of silver nitrate solution (9.3 mL), the concentration of silver nitrate solution (0.1 mol L -1 ), drying temperature (80°C), final heat treatment temperature (450°C) and heat treatment time (1 h) are all the same as in Example 1. The results showed that when the stirring time was 1, 2, 5 and 20 h, the prepared Ag / Ag(I)-TiO 2 The degradation rate of methyl orange by nanocrystalline photocatalyst is 0.095-0.105 min -1 between. The reason may be that AgNO 3 solution and TiO 2 It is easier to achieve adsorption-desorption equilibrium between nanocrystals, so that the photocatalytic properties of the final samples are comparable. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com