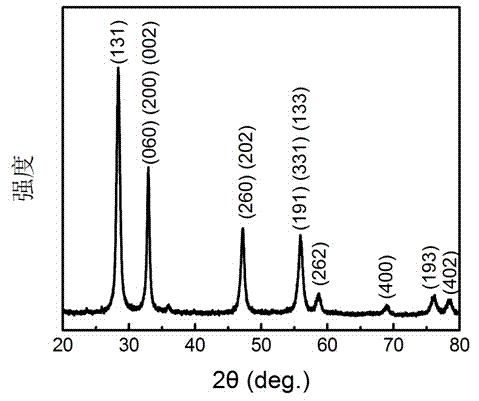

Preparation of Bi2WO6 spherical cluster with exposed {010} crystal plane families

A spherical and crystal-faced technology, applied in the field of preparation of Bi2WO6 spherical clusters, can solve the problems of environmental pollution, difficult to completely remove organic additives, and affect product performance, etc., and achieve the effect of improving the adhesion of dyes and improving the catalytic performance of visible light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

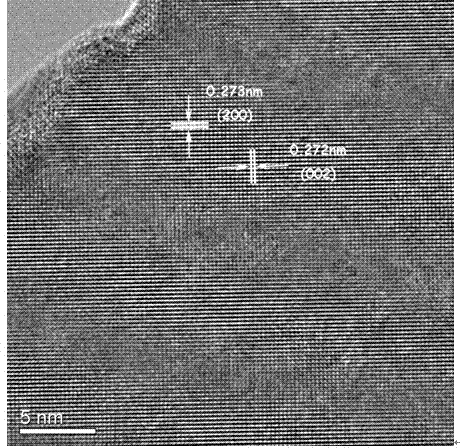

Embodiment 1

[0021] 0.97g Bi(NO 3 ) 3 ·5H 2 O dissolved in 10 mL of 1M HNO 3 , magnetically stirred for 60min, then, 0.33g Na 2 WO 4 2H 2 O was dissolved in 10mL deionized water, sonicated for 5min, and Na 2 WO 4 Add all the above Bi(NO 3 ) 3 HNO 3 In the solution, use 2M NaOH to adjust the pH of the mixed solution to 7. Finally, use deionized water to make up the total volume of the solution to 40mL, stir for 10h, then put it into the reaction kettle, heat it in an oven at 160°C for 11h, and Use 100mL deionized water to filter 5 times until the obtained precipitate is washed clean, and then freeze-dry at -50°C to obtain Bi with exposed {010} crystal faces 2 WO 6 spherical clusters. The diameter of the cluster is 2-4 μm, and it is composed of nanosheets with a thickness of about 18 nm.

[0022] The above prepared Bi with exposed {010} facets 2 WO 6 Spherical clusters were tested for visible light degradation of Rhodamine B, in which the dark reaction process was used to char...

Embodiment 2

[0024] The steps and process of this embodiment are the same as in Example 1, except that the time of the hydrothermal reaction is changed from 11h to 7h. Prepared Bi 2 WO 6 The diameter of the spherical cluster is 2-4 μm, and the spherical cluster is formed by stacking nanosheets with an average thickness of 23 nm.

Embodiment 3

[0026] The steps and process of this example are the same as Example 1, except that the temperature of the hydrothermal reaction is changed from 160°C to 180°C, and the time is changed from 11h to 7h. Prepared Bi 2 WO 6The diameter of the spherical cluster is 2-4 μm, and the spherical cluster is stacked by nanosheets with an average thickness of 16 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com