Preparation method of nitrogen-doped TiO2 microspheres with hollow core-shell structure

A technology of core-shell structure and microspheres, which is applied in the field of preparation of nitrogen-doped TiO2 microspheres, can solve the problems of enhancement, cumbersome process, and affecting product stability, and achieve the goals of enhancing contact, increasing application range, and improving visible light catalytic ability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

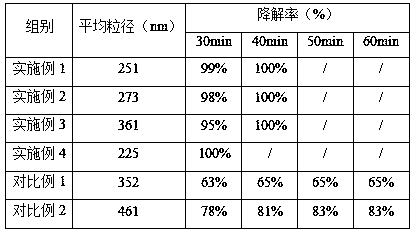

Examples

Embodiment 1

[0027] Step 1: To prepare titanium dioxide sol, mix butyl titanate and absolute ethanol at a ratio of 1:5, and shake well to obtain a mixed solution. Take 10ml of the mixed solution and add it dropwise to 35ml. The concentration of the substance is 1 mol / L of nitric acid solution, stirring continuously during the process to prevent coagulation until a colorless and transparent titanium dioxide sol is formed;

[0028] Step 2: Preparation of PAM@TiO 2 For single-shell core-shell microspheres, mix the titanium dioxide sol prepared in step 1 with an aqueous polyacrylamide solution with a concentration of 0.15%, add the initiator ammonium persulfate to cause a polymerization reaction, and wash the polymerization product with anhydrous formaldehyde, Nitrogen drying, anhydrous acetone cleaning and nitrogen drying to obtain single-shell core-shell microspheres wrapped with polyacrylamide on the surface of titanium dioxide;

[0029] Step 3: Preparation of SiO 2 @PAM @TiO 2 Double-s...

Embodiment 2

[0032] Step 1: Prepare titanium dioxide sol, mix butyl titanate and absolute ethanol according to the amount of substance at 1:3, shake well to obtain a mixed solution, take 10ml of the mixed solution and add it dropwise to 20ml with a concentration of 0.8mol / L of nitric acid solution, stirring continuously during the process to prevent coagulation until a colorless and transparent titanium dioxide sol is formed;

[0033] Step 2: Preparation of PAM@TiO 2For single-shell core-shell microspheres, mix the titanium dioxide sol prepared in step 1 with an aqueous polyacrylamide solution with a concentration of 0.1%, add an initiator potassium persulfate to cause a polymerization reaction, and wash the polymerization product with anhydrous formaldehyde, Nitrogen drying, anhydrous acetone cleaning and nitrogen drying to obtain single-shell core-shell microspheres wrapped with polyacrylamide on the surface of titanium dioxide;

[0034] Step 3: Preparation of SiO 2 @PAM @TiO 2 Doubl...

Embodiment 3

[0037] Step 1: Prepare titanium dioxide sol, mix butyl titanate and absolute ethanol according to the amount of the substance at 1:8, shake well to obtain the mixed solution, take 10ml of the mixed solution and add it dropwise to 50ml of the substance with a concentration of 1.5mol / L of nitric acid solution, stirring continuously during the process to prevent coagulation until a colorless and transparent titanium dioxide sol is formed;

[0038] Step 2: Preparation of PAM@TiO 2 For single-shell core-shell microspheres, mix the titanium dioxide sol prepared in step 1 with an aqueous solution of polyacrylamide with a concentration of 0.25%, add the initiator sodium bisulfite to cause polymerization, and wash the polymerization product with anhydrous formaldehyde , nitrogen drying, anhydrous acetone cleaning and nitrogen drying to obtain single-shell core-shell microspheres wrapped with polyacrylamide on the surface of titanium dioxide;

[0039] Step 3: Preparation of SiO 2 @PA...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com