Novel high-speed train pantograph sliding block material

A technology for high-speed trains and pantographs, applied in circuits, electrical switches, collectors, etc., can solve problems such as the influence of wear performance, traditional composition and technology, and difficult performance breakthroughs, and achieve high weather resistance and processing technology Simple, good machinability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 (preferred embodiment)

[0033] (1) Mixing: Use a metal powder mixer (maximum capacity: 100kg) with a rotation speed of 34r / min. Change the rotation direction of the mixer every 15 minutes to allow the materials to be fully mixed.

[0034] (2) Experimental material: copper powder (Cu), 400 mesh, 87%;

[0035] Titanium silicon carbide (Ti 3 SiC 2 ), 200 mesh, 10%;

[0036] Graphite (C), 200 mesh, 3%;

[0037] (3) Initial pressure: 240 tons of pressure is used for initial pressure.

[0038] (4) Sintering: using a stepwise heating method, such as Figure 9 The temperature curve shown.

[0039] (5) Cooling: During the cooling process, hydrogen protection is used until the temperature drops to 200 o Below C.

[0040] (6) Subsequent processing: Necessary turning, cutting, drilling and other finishing and surface treatment of the formed test block.

[0041] Compared with the existing similar materials, the material obtained in this embodiment has ex...

Embodiment 2

[0049] The preparation method of this embodiment is the same as that of Example 1.

[0050] Experimental material: copper powder (Cu), 400 mesh, 90%;

[0051] Titanium silicon carbide (Ti 3 SiC 2 ), 200 mesh, 7%;

[0052] Ink (C), 200 mesh, 3%.

[0053] Compared with the existing similar materials, the material obtained in this embodiment has excellent comprehensive physical properties, and can realize the control of material properties by the process. It also has a certain protective effect.

[0054] The performance characteristics of the material are as follows:

[0055] Impact toughness tensile strength density Rockwell hardness coefficient of friction Conductivity 2.4J / cm 2 102MPa 6.5g / cm 3 72HB 0.38 74%IACS

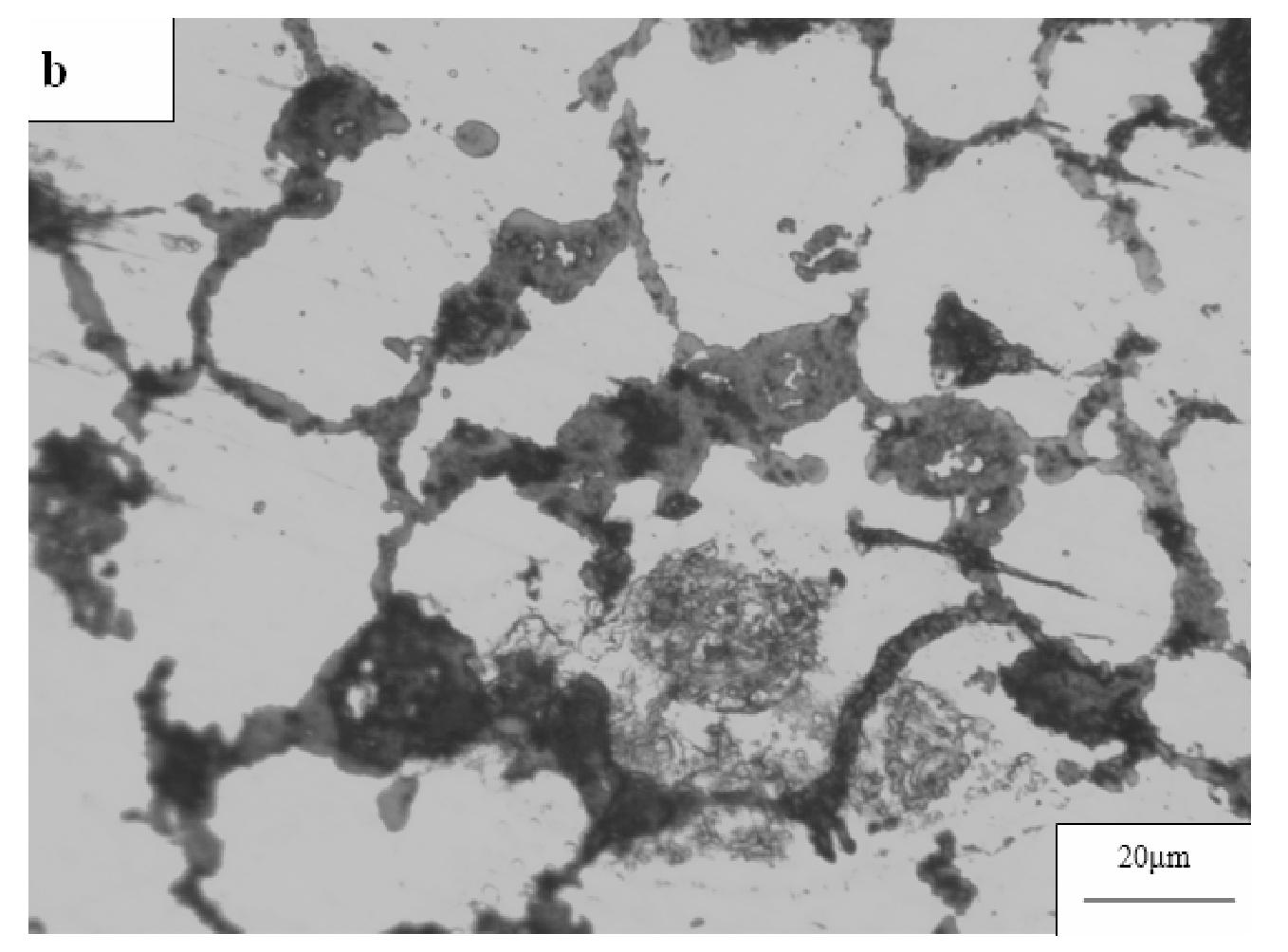

[0056] see figure 2 Be the metallographic structure photograph of present embodiment material, from figure 2 It can be seen that the copper matrix (bright area) is distributed in a network, ...

Embodiment 3

[0060] The preparation method of this embodiment is the same as that of Example 1.

[0061] Experimental material: copper powder (Cu), 400 mesh, 84%;

[0062] Titanium silicon carbide (Ti 3 SiC 2 ), 200 mesh, 13%;

[0063] Ink (C), 200 mesh, 3%.

[0064] Compared with the existing similar materials, the material obtained in this embodiment has excellent comprehensive physical properties, and can realize the control of material properties by the process. It also has a certain protective effect.

[0065] The performance characteristics of the material are as follows:

[0066] Impact toughness tensile strength density Rockwell hardness coefficient of friction Conductivity 1.8J / cm 2 89MPa 5.5g / cm 3 70HB 0.38 74%IACS

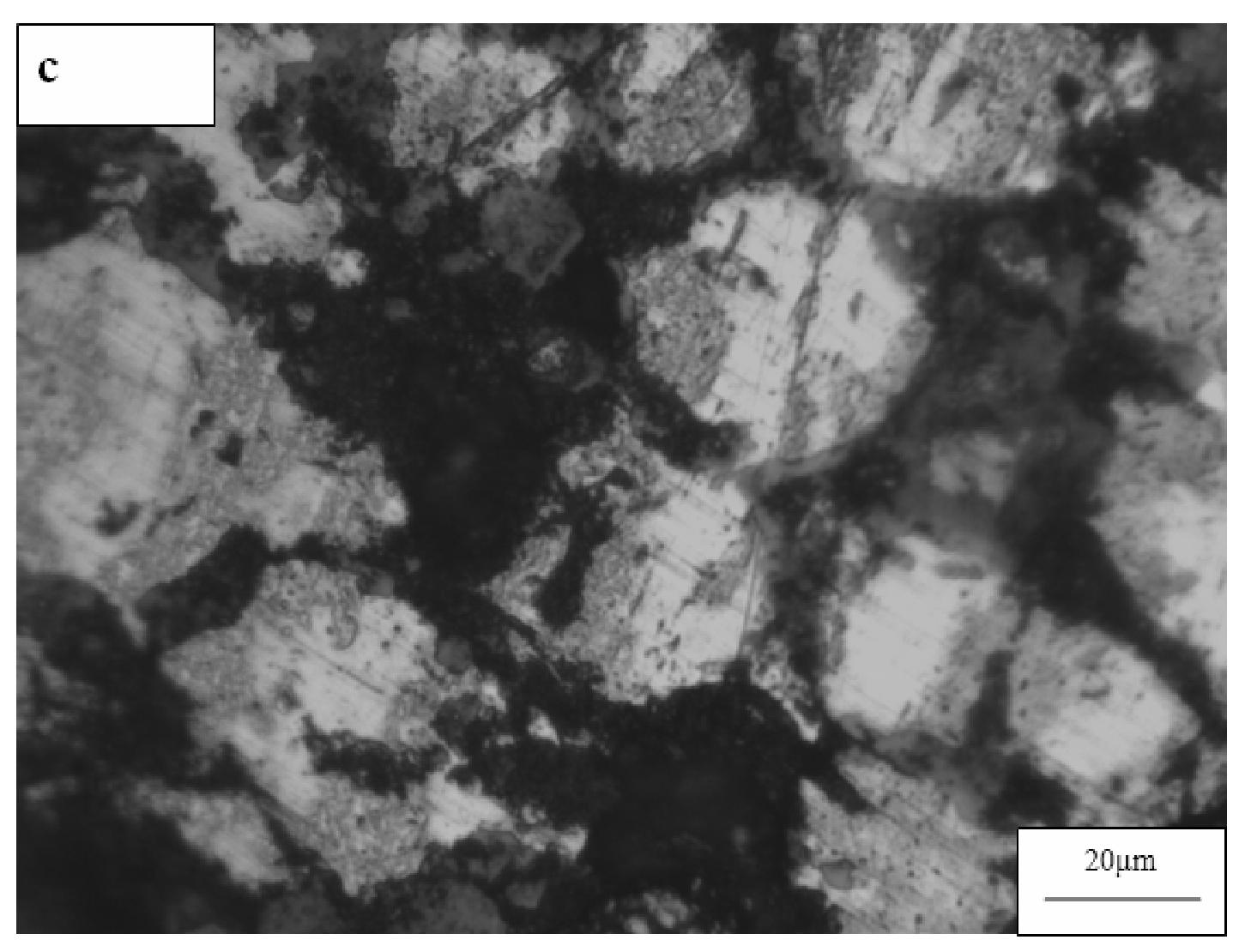

[0067] see image 3 Be the metallographic structure photograph of present embodiment material, from image 3 It can be seen that in some areas, the copper matrix (bright area) is covered by Ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com