Method for improving effective blending of polymers with different viscosities by aid of supercritical fluids

A supercritical fluid and polymer technology, which is applied in the field of polymer processing, can solve the problems of poor compatibility and inefficiency, and achieve the effect of simple recycling and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

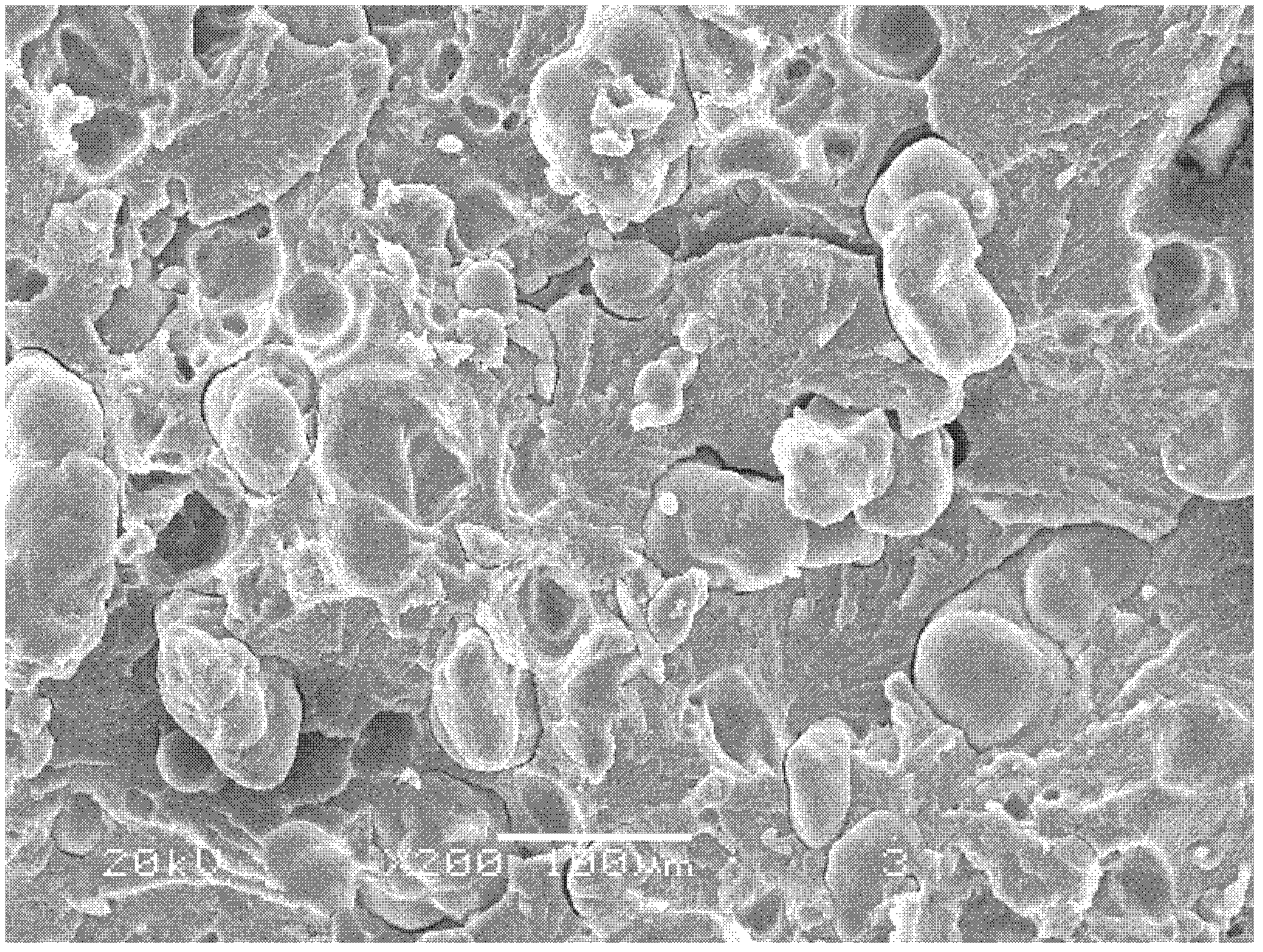

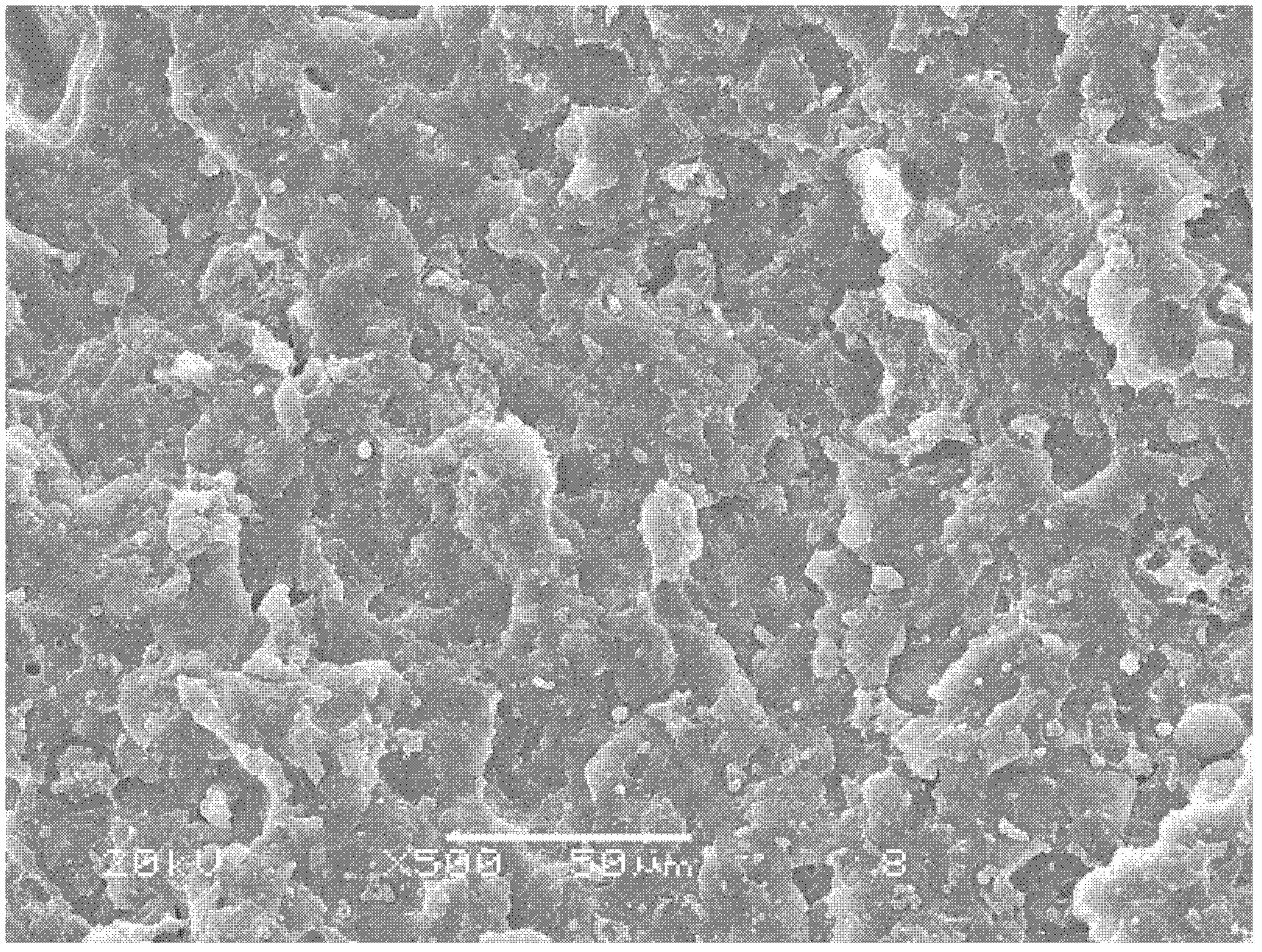

Image

Examples

Embodiment 1

[0025] Polystyrene (melt flow rate 1.5g / 10min) and low density polyethylene (melt flow rate 40g / 10min) are two polymers with widely different viscosities. Stir and mix 50kg of polystyrene and 50kg of low-density polyethylene, and then add them to the feed zone or hopper of a twin-screw extruder with an aspect ratio L / D of 32:1, and inject the polymer mixed melt The speed is 500g / min. The supercritical carbon dioxide fluid is continuously injected into the polymer mixed melt through the air hole on the barrel of the twin-screw extruder. The injection speed of the supercritical carbon dioxide fluid is 2g / min, and the control screw speed is: 100 rpm, Control the temperature of the twin-screw from the feed section to the head to 150°C, 170°C, 170°C, 160°C respectively, and the temperature of the head to 155°C. The first viscosity of body satisfies following relational formula: (the initial viscosity of mixed melt-the first viscosity of mixed melt) ÷ the initial viscosity of mixed...

Embodiment 2

[0034] Ultra-high molecular weight polyethylene (melt flow rate is close to 0g / 10min) and nylon 66 (melt flow rate is 20g / 10min) are two polymers with a large difference in viscosity. 30kg of ultra-high molecular weight polyethylene and 70kg of After the ultra-high molecular weight polyethylene is stirred and mixed evenly, it is added to the feed zone or hopper of a twin-screw extruder with an aspect ratio L / D of 48:1, and the injection speed of the polymer mixed melt is 2000g / min. The supercritical ethane fluid is continuously injected into the polymer mixed melt through the air holes on the barrel of the twin-screw extruder. The injection speed of the supercritical ethane fluid is 6g / min, and the control screw speed is: 300 rpm Points, control the temperature of the twin-screw from the feed section to the machine head to 200°C, 235°C, 235°C, 215°C respectively, and the temperature of the machine head to 205°C, extrude and granulate, this process can ensure stirring in the mol...

Embodiment 3

[0043] Polystyrene (melt flow rate 1.5g / 10min) and low density polyethylene (melt flow rate 40g / 10min) are two polymers with widely different viscosities. Stir and mix 60kg of polystyrene and 50kg of low-density polyethylene, and then add them to the feed zone or hopper of a twin-screw extruder with a length-to-diameter ratio of L / D of 32:1. The injection of the polymer mixed melt The speed is 1000g / min. The supercritical carbon dioxide fluid is continuously injected into the polymer mixed melt through the air hole on the barrel of the twin-screw extruder, the injection speed of the supercritical nitrogen fluid is 4g / min, and the control screw speed is: 200 rpm, Control the temperature of the twin-screw from the feed section to the head to 150°C, 170°C, 170°C, 160°C respectively, and the temperature of the head to 155°C. The first viscosity of body satisfies following relational formula: (the initial viscosity of mixed melt-the first viscosity of mixed melt) ÷ the initial vis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com