Discontinuous metallic silver membrane and membrane coating method for same

A metal texture, silver-white technology, applied in metal material coating process, sputtering plating, ion implantation plating, etc., can solve the problems of poor mechanical strength, easy oxidation, poor adhesion, etc., to achieve mechanical strength Good, good film adhesion, conducive to the effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A coating method for a discontinuous silver-white film with a metallic texture. The coating method uses an environmentally friendly coating material (titanium dioxide silicon dioxide) as a raw material, and introduces optical vacuum coating technology. According to the specific characteristics of the glass panel material of the capacitive touch screen of a mobile phone, the design And optimize each parameter of optical vacuum coating technology, can effectively solve the deficiencies in the prior art through verification, realize the object of the present invention, this coating method specifically comprises the following steps:

[0028] Step 1: Prepare silver-white film by optical vacuum coating:

[0029] (1) Optical vacuum coating machine model: (United vacuum 2050 coating machine)

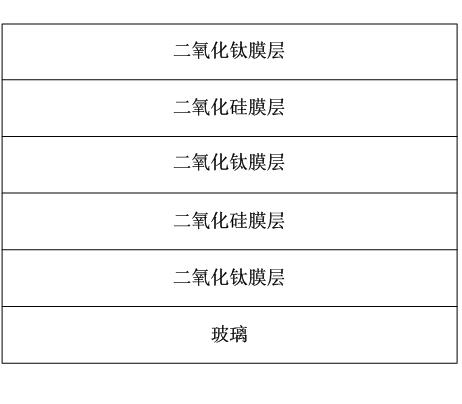

[0030] (2) Film structure: glass substrate / titanium dioxide / silicon dioxide / titanium dioxide / silicon dioxide / titanium dioxide / air

[0031] (3) Preparation of coating process:

[0032] T...

Embodiment 2

[0049] A coating method for a discontinuous metallic silver-white thin film. The coating method uses environmentally friendly coating materials (titanium dioxide, silicon dioxide) as raw materials, and introduces optical vacuum coating technology. According to the specific characteristics of the glass panel material of the capacitive touch screen of the mobile phone, Designing and optimizing various parameters of the optical vacuum coating technology can effectively solve the deficiencies of the prior art and realize the purpose of the present invention. The coating method specifically includes the following steps:

[0050] Step 1: Prepare silver-white film by optical vacuum coating:

[0051] (1) Optical vacuum coating machine model: (United vacuum 2050 coating machine)

[0052] (2) Film structure: glass substrate / titanium dioxide / silicon dioxide / titanium dioxide / silicon dioxide / titanium dioxide / air

[0053] (3) Preparation of coating process:

[0054] The film system is a r...

Embodiment approach 3

[0071] A coating method for a discontinuous silver-white film with a metallic texture. The coating method uses an environmentally friendly coating material (titanium dioxide silicon dioxide) as a raw material, and introduces optical vacuum coating technology. According to the specific characteristics of the glass panel material of the capacitive touch screen of a mobile phone, the design And optimize each parameter of optical vacuum coating technology, can effectively solve the deficiencies in the prior art through verification, realize the object of the present invention, this coating method specifically comprises the following steps:

[0072] Step 1: Prepare silver-white film by optical vacuum coating:

[0073] (1) Optical vacuum coating machine model: (United vacuum 2050 coating machine)

[0074] (2) Film structure: glass substrate / titanium dioxide / silicon dioxide / titanium dioxide / silicon dioxide / titanium dioxide / air

[0075] (3) Preparation of coating process:

[0076] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com