Mortar cyclic utilization device of multi-wire cutting machine

A multi-wire cutting machine and mortar technology, which is applied to fine working devices, working accessories, stone processing equipment, etc., can solve the problems of reducing work efficiency, generating chips and chips, and increasing processing costs, so as to improve processing accuracy and processing. Efficiency, reducing the possibility of clogging the pipeline, prolonging the service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with specific drawings.

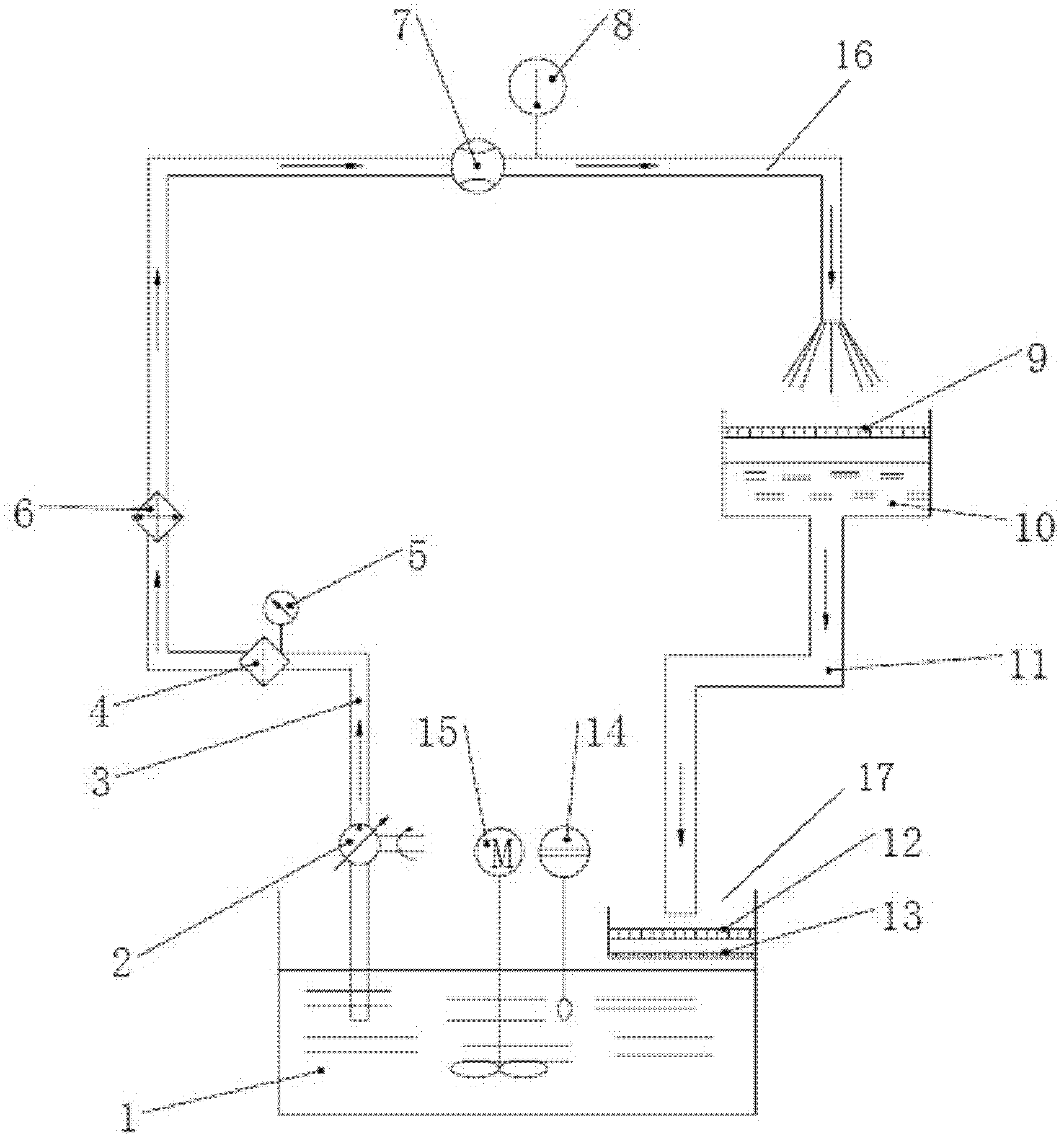

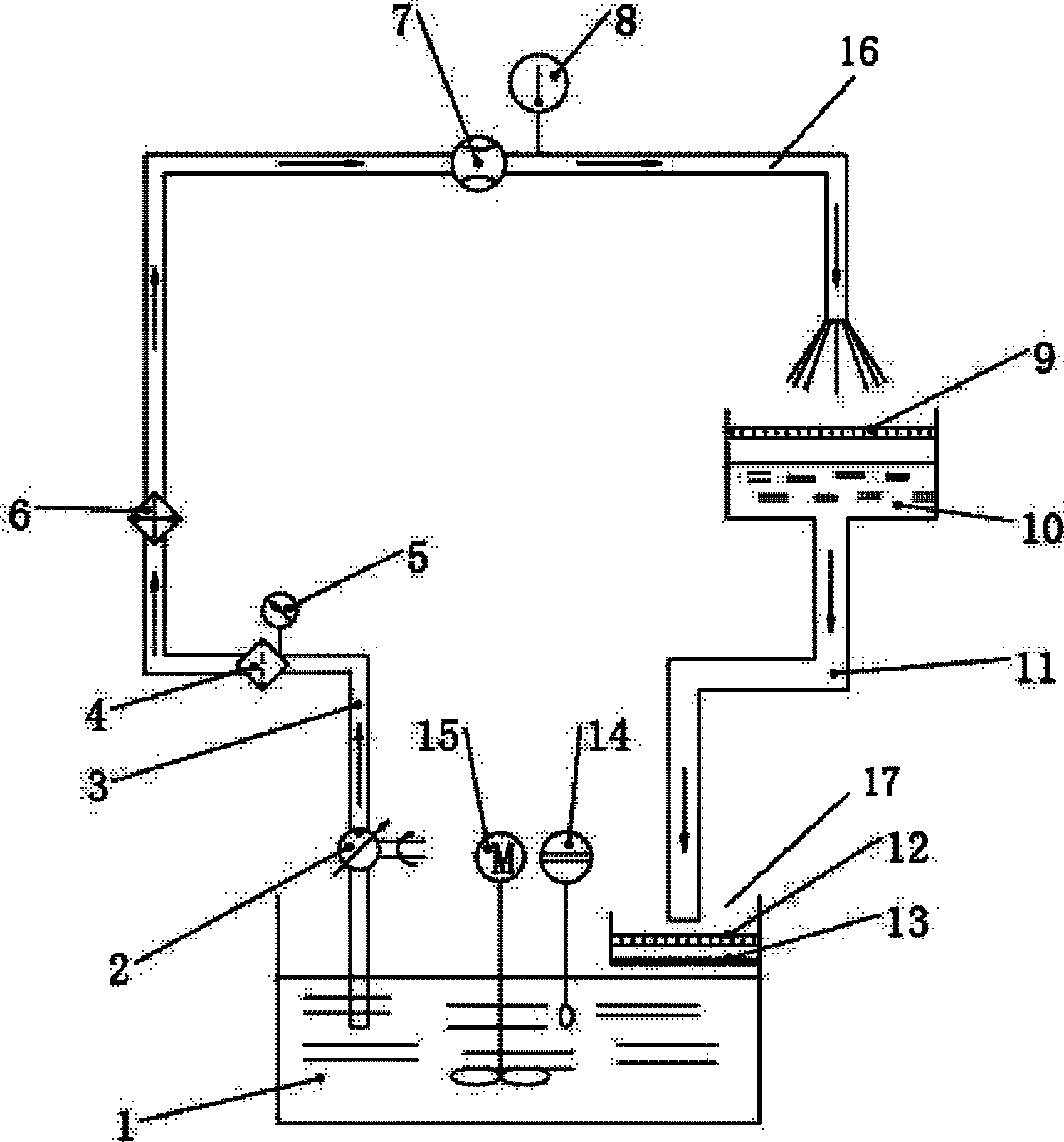

[0012] As shown in the figure: the circulating water cooling device of the multi-wire cutting machine includes a mortar bucket 1, a sand pump 2, a sand supply pipeline 3, a bag filter 4, a pressure sensor 5, a heat exchanger 6, a mass flow meter 7, a temperature Inductor 8, first coarse stainless steel filter 9, liquid receiving tank 10, sand return pipeline 11, second coarse stainless steel filter 12, fine stainless steel filter 13, liquid level gauge 14, stirring motor 15, sandblasting pipeline 16. Back to sand mouth 17, etc.

[0013] The present invention comprises a mortar tank 1, on which a sand supply pipeline 3 is connected, on which a sand pump 2, a bag filter 4, a heat exchanger 6, a mass flow meter 7 and Temperature sensor 8, the sand supply pipeline 3 is connected with the sandblasting pipeline 16, the liquid receiving tank 10 is arranged below the sandblasting ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com