Standard sample for spectral analysis of free cutting steel SAE1215

A SAE1215, spectral analysis technology, applied in the field of standard samples for free-cutting steel SAE1215 spectral analysis, can solve the problem of difficult to find alloy steel spectral standard samples, and achieve the effects of good uniformity, convenient use and accurate value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

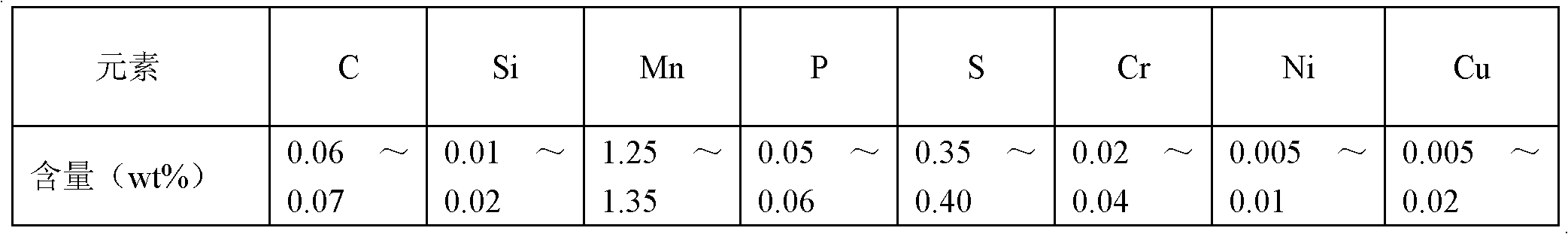

[0014] 1. Composition design: iron is the matrix component, the alloy element composition and its content are shown in Table 1, and the content of other impurity elements is less than 0.005wt%.

[0015] 2. Preparation method:

[0016] (1) Design the ingredients according to the composition in Table 1, smelt in a 500kg intermediate frequency induction furnace, use induction magnetic stirring to ensure the uniformity of the molten steel composition, and use pure aluminum as the deoxidizer; use a 180mm ingot metal mold and cast molding;

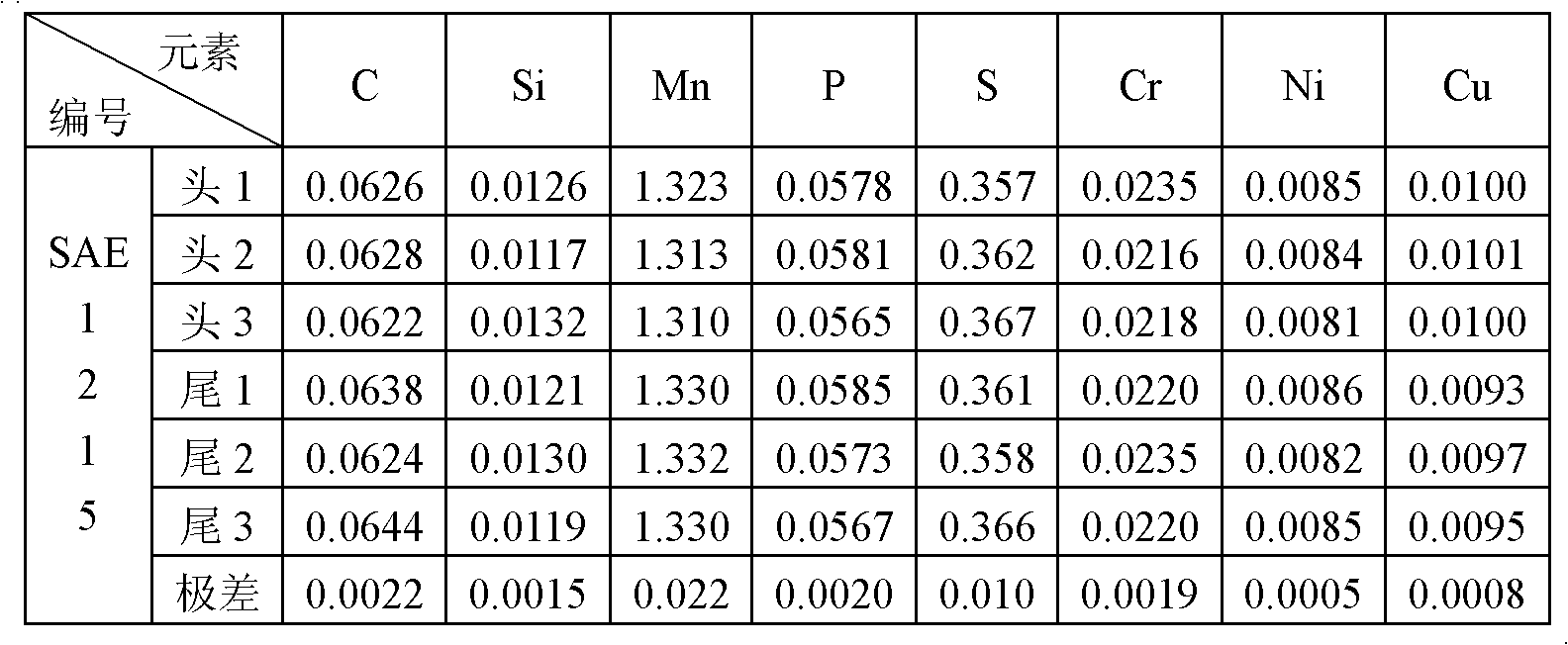

[0017] (2) The steel ingot is forged at 1200℃±50℃ for 3 hours and then forged into a square billet of 80mm×80mm×2000mm, and air-cooled; then the main elements are segregated and the range method is used to determine the result; Keep it at ℃±50℃ for 1 hour, hot-rolled into a round bar of Φ45mm×2500mm;

[0018] (3) Number the rolled round bars, remove the scale, and flatten them into a Φ40mm×40mm spectrum block.

[0019] 3. The uniformity inspection of sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com