Method for preparing microcrystalline silicon film by two-step method of ion beam and magnetron sputtering and device for coating composite film by ion beam and magnetron sputtering

A technology of magnetron sputtering coating and microcrystalline silicon thin film, which is applied in the field of preparation of microcrystalline silicon thin film, can solve problems such as metal ion pollution, potential safety hazards, and increased manufacturing cost, and achieve simple process operation, reduced manufacturing cost, and reduced The effect of equipment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] An ion beam magnetron sputtering composite coating device, such as Picture 10 , Picture 11 As shown, it is specifically a vacuum chamber (1), the top of the vacuum chamber is provided with a medium energy implantation ion source (2) leading to the vacuum chamber, and the left and right side walls of the vacuum chamber are each provided with a sputtering chamber leading to the vacuum chamber Ion source (7), a low-energy auxiliary ion source (3) leading to the vacuum chamber is arranged above the back wall of the vacuum chamber, and two suction pipes (10) connected to the molecular pump are arranged under the rear wall of the vacuum chamber; There is a sample stage (8), the sample stage (8) is connected to the bottom of the vacuum chamber through a rotating shaft (9); two magnetron sputtering target heads (5) arranged symmetrically on the top of the sample stage (8), magnetron The sputtering target head (5) is connected with the top of the vacuum chamber through a magnetro...

Embodiment 2

[0050] The device described in Example 1 is used to realize a method of the present invention for preparing a microcrystalline silicon film by a two-step ion beam magnetron sputtering method:

[0051] Pulse magnetron sputtering deposition of microcrystalline silicon film, the target is polycrystalline silicon, the background vacuum is ≤1×10 -4 Pa, the hydrogen volume concentration is 70%.

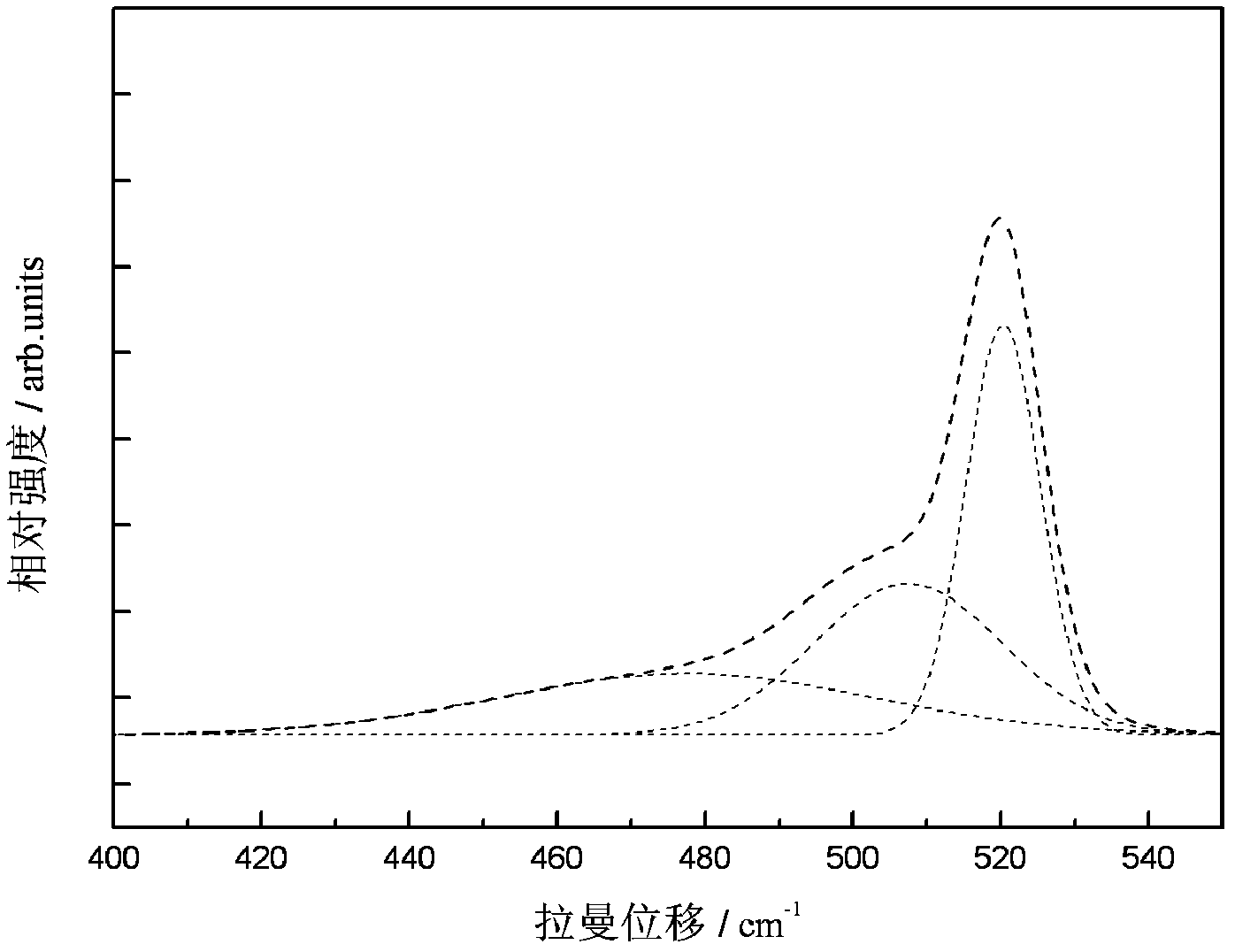

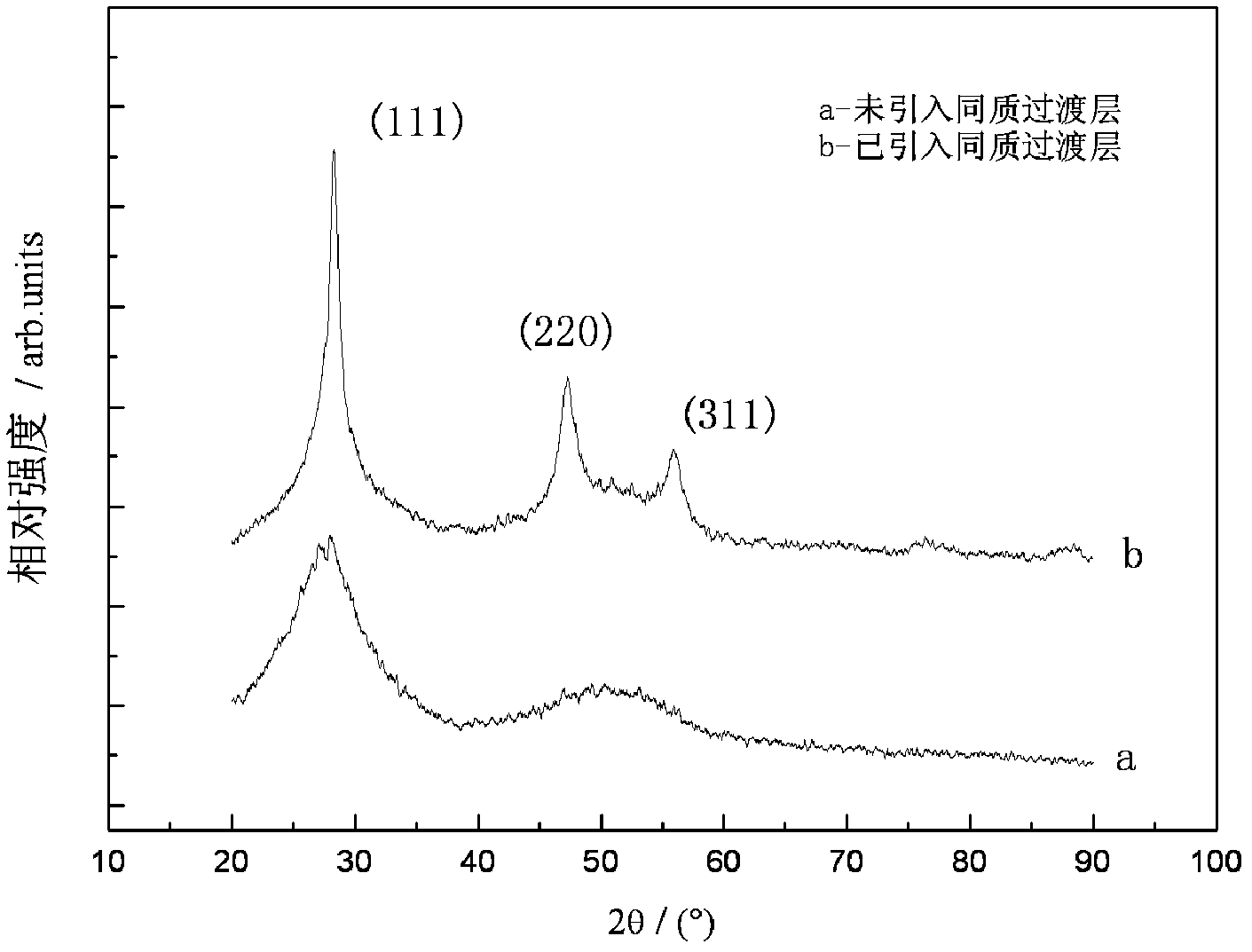

[0052] Common glass slides are used as the substrate, followed by ultrasonic cleaning with acetone and alcohol. After drying, they are placed on the sample table in the vacuum chamber of the ion beam magnetron sputtering composite coating equipment. The surface is cleaned by bombardment with low energy ion beams for 15 minutes before coating. Then an ion beam is used to assist the deposition of a silicon homogenous transition layer with a thickness of 68nm, that is, Ar with 2.5keV energy in use + While ion beam sputtering polycrystalline Si target, use another beam of Ar with energy of 30keV + Th...

Embodiment 3

[0057] The device described in Example 1 is used to realize a method of the present invention for preparing a microcrystalline silicon film by a two-step ion beam magnetron sputtering method:

[0058] Pulse magnetron sputtering deposition of microcrystalline silicon film, the target is polycrystalline silicon, the background vacuum is ≤1×10 -4 Pa, the hydrogen volume concentration is 80%.

[0059] Use ordinary glass slides as the substrate, followed by ultrasonic cleaning with acetone and alcohol. After drying, they are placed on the sample table in the vacuum chamber of the ion beam magnetron sputtering composite coating equipment. The surface is cleaned by bombardment with low energy ion beams for 15 minutes before coating. Then use 3.5keV Ar + Ion beam sputtering a polycrystalline Si target to deposit a silicon homogenous transition layer with a thickness of 117nm. After the transition layer is deposited, without breaking the vacuum, the sample table is transferred from the ion ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com