Preparing technology of high-performance straw fiber plastic-wooden composite material

A wood-plastic composite material and straw fiber technology, which is applied in the field of preparation technology of high-performance straw fiber wood-plastic composite material, can solve the problem that the tensile strength, impact resistance strength, Vicat softening temperature and other application properties of the wood-plastic composite material are not up to the standard. It can achieve the effect of sensitive and easy control, increase the apparent crystallinity, and change the hydrogen bonding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

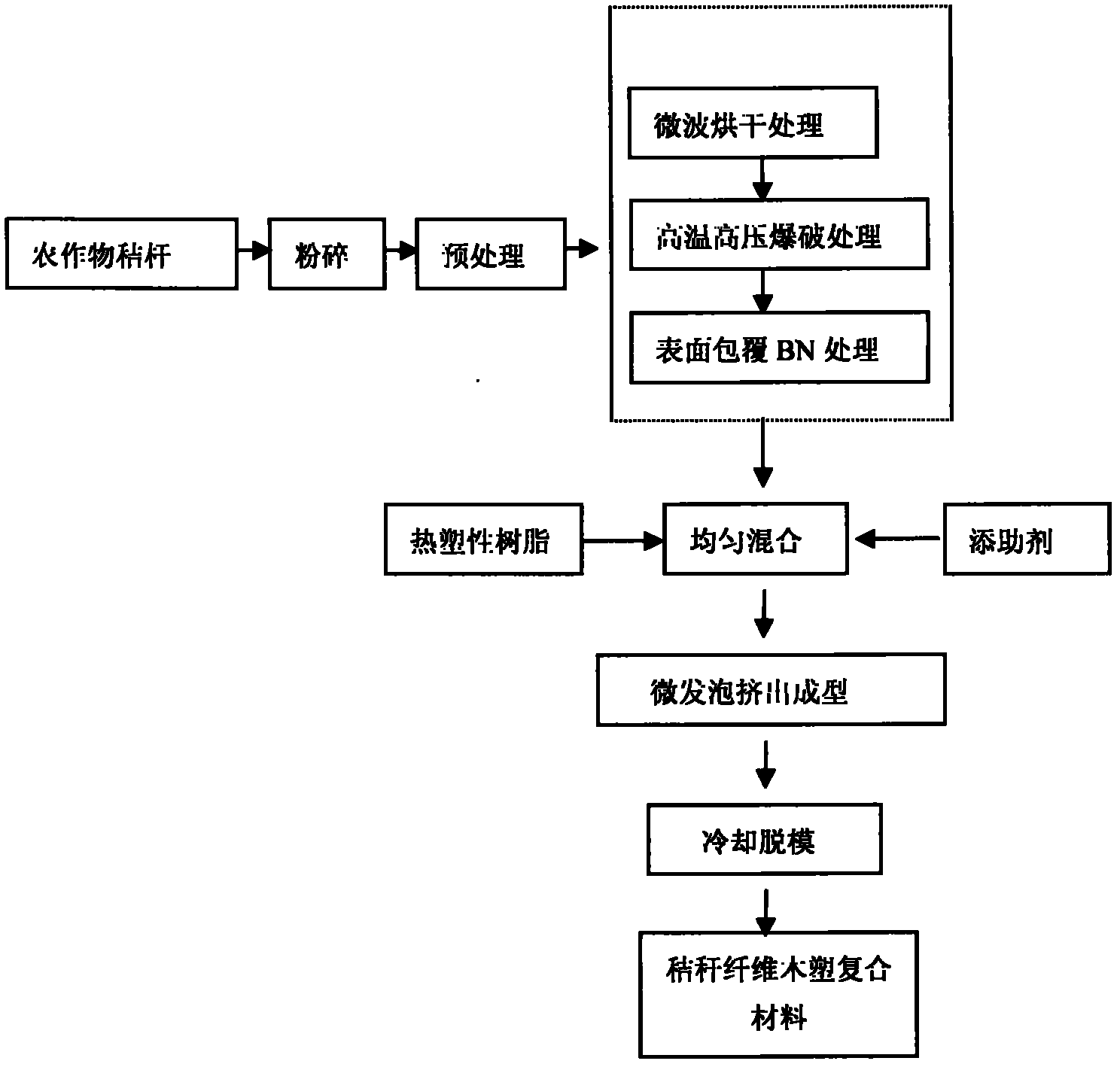

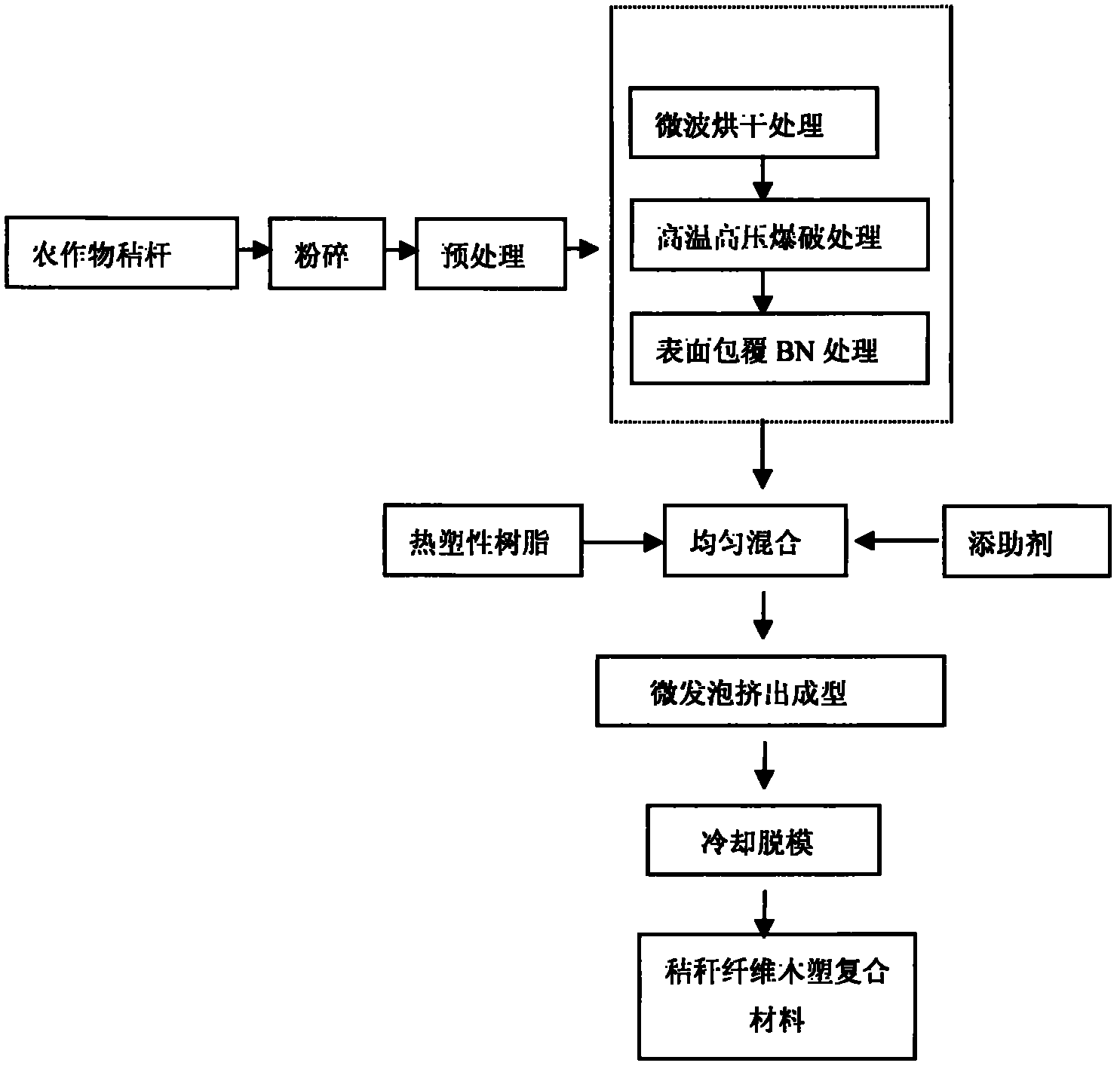

[0014] refer to figure 1 , the specific implementation method adopts the following technical scheme: its preparation process is: using rice straw as a raw material, after microwave drying treatment, high temperature and high pressure steam explosion modification treatment and inorganic nano boron nitride coating modification pretreatment, It is evenly mixed with thermoplastic resin, interface modifier and other additives, and then micro-foamed and extruded in a mold after being evenly mixed, and then cooled and demolded.

[0015] The method for determining the parameters of each process link in the preparation process of this specific embodiment is: using an extra-fiber spectrometer (IR) to analyze the hydroxyl structure and content of the straw fiber; using an X-ray diffractometer (XRD) to analyze the structure and composition of the material ; Observe the microstructure and morphology of straw fibers with scanning electron microscope (SEM) and transmission electron microscop...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com