High-tenacity conducting nanocomposite material and preparation method thereof

A composite material and conductive nano technology, which is applied in the field of high-toughness conductive nano-composite materials and its preparation, can solve the problems that the electrical and mechanical properties of materials cannot be improved at the same time, so as to improve energy transfer efficiency, improve electrical conductivity, and have high industrial compatibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Step 1: Heat the mixer to 100°C, add 500g of nano-calcium carbonate (particle size 15-40nm) to remove the water in the particles. Then 15g of boron-aluminum-titanium composite coupling agent-purchased from Shanxi Ruicheng Xintai Nano Material Co., Ltd. was added, and the modified nano-calcium carbonate was obtained after uniform mixing;

[0026] Step 2: Take 300g of the modified nano calcium carbonate obtained in Step 1 and 670g of high-density polyethylene (density 0.95g / cm 3 ) Mix uniformly in a mixer to obtain a mixture;

[0027] Step 3: Add 30g of carbon nanotubes (tube diameter 20-30nm, length 10-30μm) to the mixture obtained in step two, and mix it evenly, then use the twin-screw extruder at 180 / 190 / 200 / 210 / 220 / 230 / 225 / Melt extrusion pelletizing at 220°C.

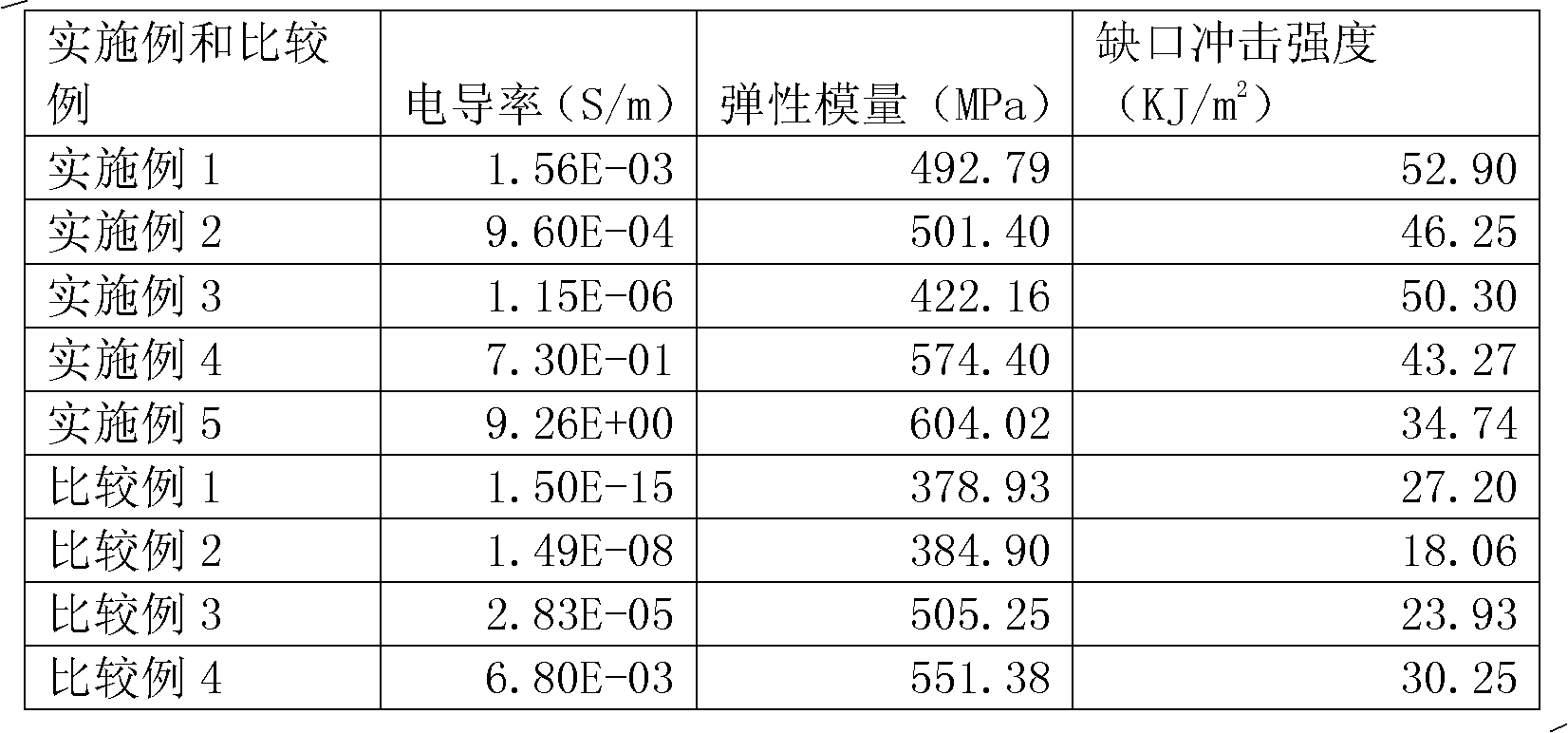

[0028] The performance test results of the obtained composite material are shown in Table 1.

Embodiment 2

[0030] The implementation method is the same as in Example 1, and the coupling agent is changed to 10g titanate coupling agent 105. The test results are shown in Table 1.

Embodiment 3

[0032] The implementation method is the same as in Example 1. The modified nano calcium carbonate is changed to 200 g, the high density polyethylene is changed to 770 g, and the carbon nano tube is changed to 30 g. The test results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com