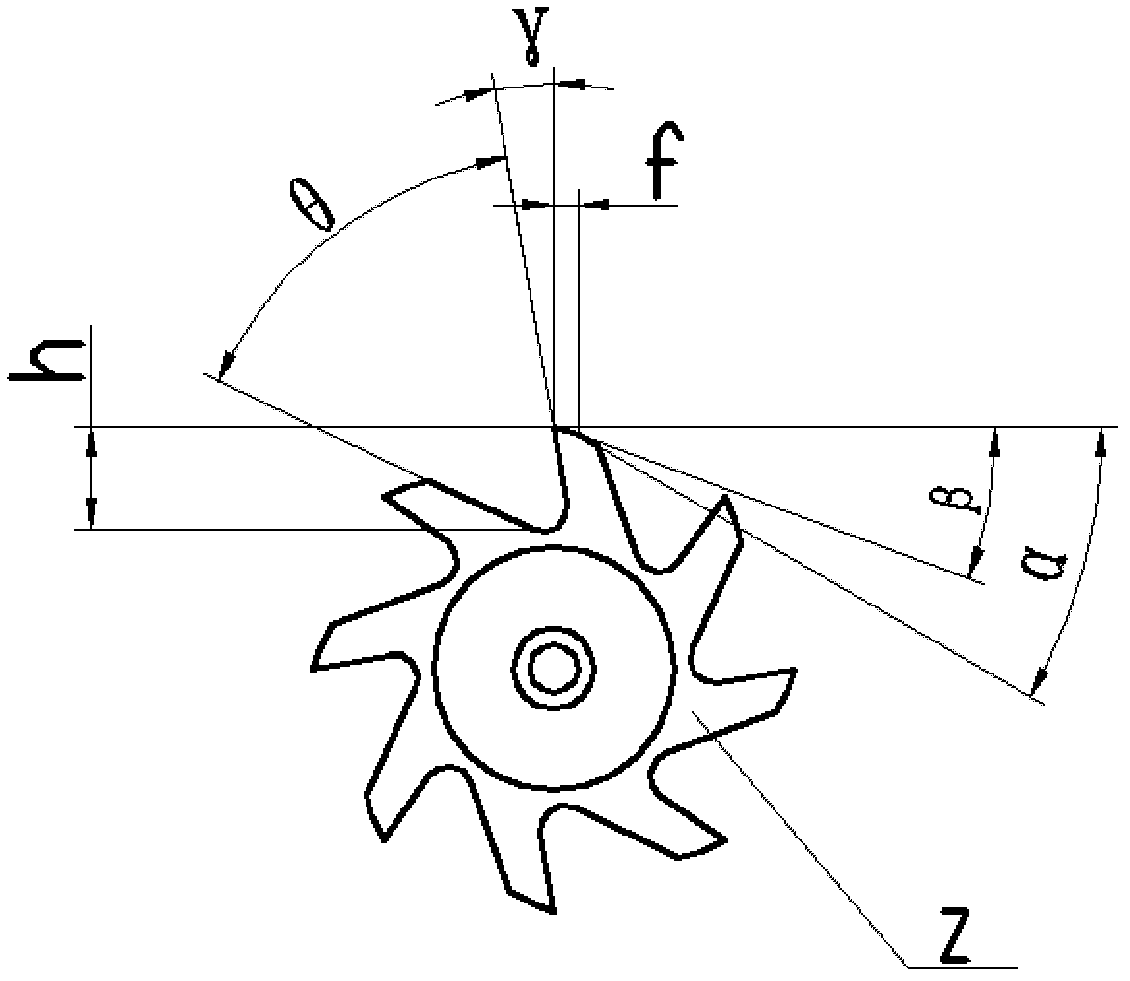

Tooth profile of narrow-grooved milling cutter

A technology for slot milling cutters and milling cutters, which is applied to milling cutters, milling machine equipment, manufacturing tools, etc. It can solve the problems of poor chip removal, blockage of tooth grooves, and low processing efficiency, so as to avoid edge jumping and improve damage durability. , The effect of smooth chip removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below. see figure 1 , 2 , a tooth shape of a narrow slot milling cutter, characterized in that: the cutter head diameter of the slot milling cutter d=20mm~60mm, the number of teeth Z=8~12, the tooth groove angle θ=50°~60°, the tooth groove depth h=3mm~8mm, rake angle γ=5°~10°, primary relief angle β=12°~18°, secondary relief angle α=20°~30°, edge width f=0.8mm~1.2mm, in The two sides of the width of the cutter head are provided with a backlash angle δ=15′~1° from the tip of the cutter to the inner side of the cutter body.

[0009] The working principle of the present invention is: because the present invention reduces the rake angle and the back angle, increases the tooth groove depth and the tooth groove angle, thereby increases the chip pocket. The milling cutter has enough chip space, reduces the milling force, prolongs the durability of the milling cutter, and improves the production efficiency.

[0010] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com