Natural gas pipe corrosion inhibitor coating device

A technology for natural gas pipelines and film coating devices, which is applied to devices for coating liquid on surfaces, spray devices, liquid spray devices, etc., can solve problems such as difference in running speed, waste of corrosion inhibitor, and inability to fill two pigs with liquid. , to achieve the effect of reducing the cost of coating film and saving consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

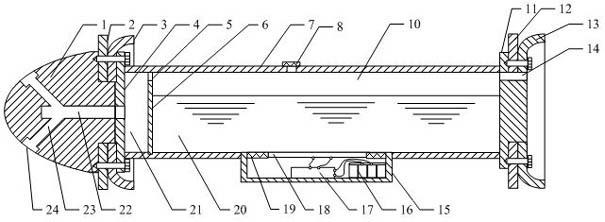

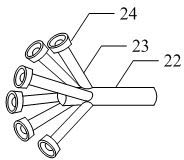

[0015] Depend on figure 1 and figure 2 It can be seen that the present invention consists of an atomizing head 1 and a tubular body 7. The atomizing head 1 is provided with an atomizing main channel 22 and an atomizing branch channel 23 communicating with it. The atomizing nozzle 24 is installed on the top of the atomizing branch channel 23. ; The front and rear ends of the tubular body 7 are respectively provided with a front cover 4 and a rear cover 11, the front cover 4 has a central hole communicating with the atomization main channel 22, and the rear cover 11 top is provided with an air-introduction through hole 14, the tubular A partition 6 is provided inside the body 7, and a ventilation hole 5 is provided on the top of the partition 6, and the tubular body 7 is divided into two chambers, a liquid storage chamber 10 and a premix chamber 21, and a corrosion inhibitor is provided above the liquid storage chamber 10. The filling port 8 is provided with an ultrasonic atom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com