Periodic subwavelength metal structure on the surface of light-emitting diode and its preparation method

A technology of light-emitting diodes and sub-wavelength structures, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of undisclosed specific size preparation methods of metal structures, obvious luminous enhancement effects, and complicated preparation processes, and achieves improvement of internal quantum efficiency. and external quantum efficiency, improve external quantum efficiency, enhance the effect of luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

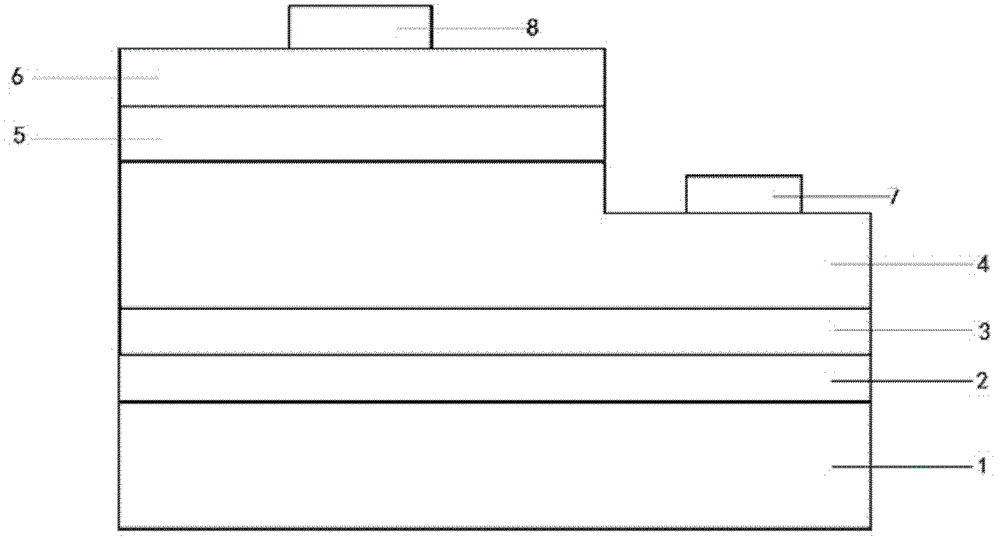

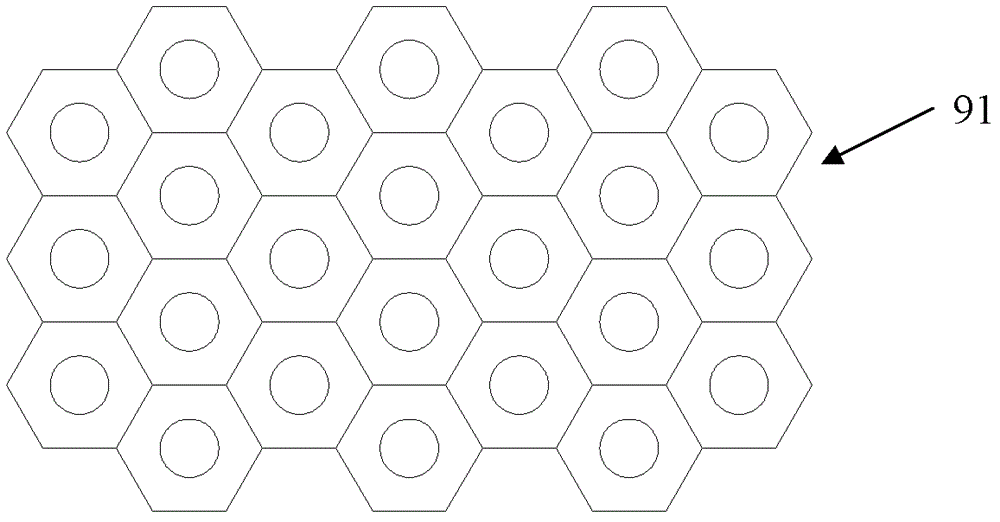

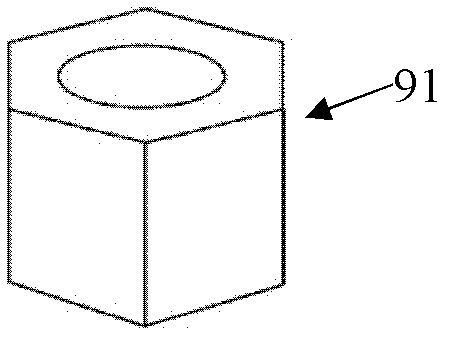

[0049] Embodiment 1: the anodic aluminum oxide (AAO) film structure used in this scheme is as follows figure 2 and shown in Figure 3. A self-made anodizing device was used for the preparation. The method for preparing the metal periodic sub-wavelength structure on the surface of the light-emitting diode comprises the following steps:

[0050] Step 1: Preparation of AAO thin film. The specific process is as follows:

[0051] Step 11: Pretreatment of aluminum flakes (99.999% pure, 0.5mm×50mm×100mm in size). Annealing, oil removal, oxide layer removal, and electropolishing are successively performed.

[0052] Step 12: An anodizing process. Using oxalic acid as electrolyte solution, lead as cathode, aluminum as anode, cooling by circulating water, magnetic stirring, steady flow control. The concentration of oxalic acid is 0.3mol / L, and the steady flow control is adopted: adjust the voltage to keep the current at 0.3-0.5A, the electrolysis temperature is 20-30°C, and the oxi...

Embodiment 2

[0065] Embodiment 2: The preparation method of the metal periodic sub-wavelength structure on the surface of the light-emitting diode comprises the following steps:

[0066] Step 1: Preparation of AAO thin film. The preparation of the AAO film in this example is the same as that described above.

[0067] Step 2: Fabrication of the isolation layer 93 .

[0068] On the surface of the InGaN light-emitting diode, the plasma-enhanced chemical vapor deposition (PECVD) method is used to deposit SiN with a thickness of 20-30nm. x The anti-reflection film is used as the isolation layer 93, and the process conditions for deposition are: the pre-vacuum degree of the reaction chamber is -3 Pa, as silane (SiH 4 ) and ammonia (NH 3 ) as the plasma gas source, the gas pressure during deposition is 60-80Pa, the temperature is 200°C-300°C (preferably 250°C), the RF power frequency is 10-15MHz (preferably 13.56MHz), and the output power is 0.2W / cm 2 .

[0069] Step 3: Fabrication of the na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com