Method for preparation and regulation of surface-roughness ZnO nano-cone or nanorod array

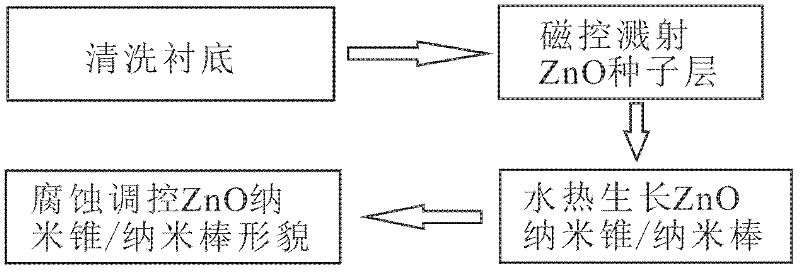

A nanorod array and surface roughening technology, which is applied in the field of nanomaterials, can solve the problems of ZnO nanocone or nanorod surface smoothness and difficult surface roughness control, so as to improve light extraction efficiency, increase specific surface area, and improve photocatalysis. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

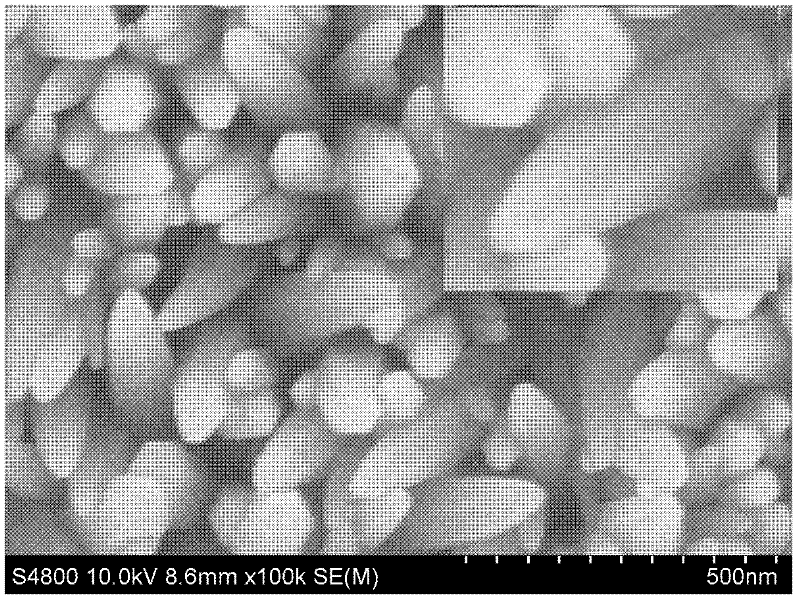

[0028] This embodiment is the process of preparing and roughing the ZnO nanocone array.

[0029] (1) Choose glass, plastic, Si sheet, LED or SiO 2 Any one of them is used as the substrate and cleaned;

[0030] (2) Sputtering a layer of dense and crystalline ZnO seed layer on the substrate at room temperature with a magnetron sputtering apparatus;

[0031](3) Hydrothermal growth of ZnO nanocone arrays: put the substrate with the ZnO seed layer prepared in step (2) into a polyamide containing zinc source precursor solution (zinc acetate, zinc nitrate or zinc sulfate solution). In the vinyl fluoride reaction kettle, the concentration of the zinc source precursor solution is 0.02M-0.1M, the reaction kettle is sealed in a stainless steel kettle jacket, and the reaction kettle and the kettle jacket are put together in a constant temperature box for heating and reaction, and the reaction temperature is 80°C-100°C , the reaction time is 2-6 hours. After the reaction is completed, th...

Embodiment 2

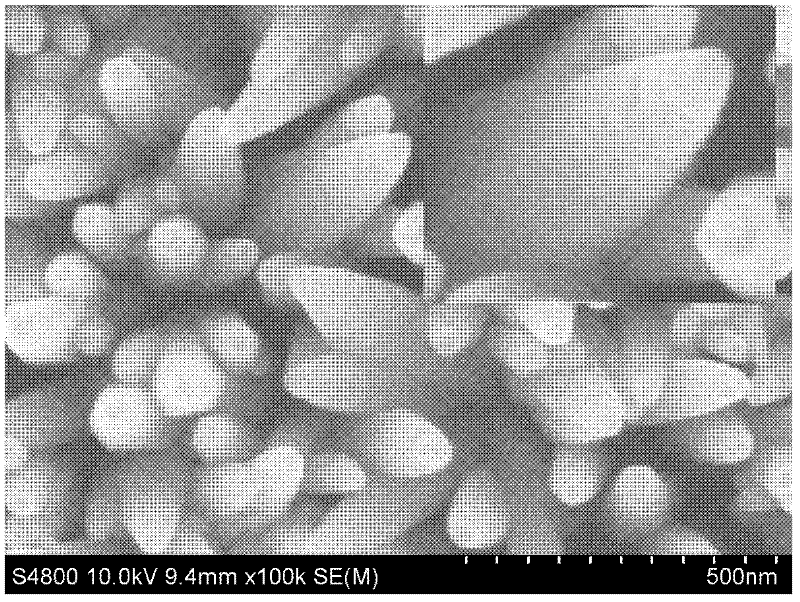

[0044] This embodiment is the process of preparing and roughening ZnO nanorod arrays.

[0045] (1) Choose glass, plastic, Si sheet, LED or SiO 2 Any one of them is used as the substrate and cleaned;

[0046] (2) Sputtering a layer of dense and crystalline ZnO seed layer on the substrate at room temperature with a magnetron sputtering apparatus;

[0047] (3) The parameters given by each experiment number in the table below adopt the hydrothermal method to grow ZnO nanorod arrays: the substrate with the ZnO seed layer prepared in step (2) is put into the precursor solution containing zinc source (zinc acetate , zinc nitrate or zinc sulfate solution) in a beaker, the concentration of the zinc source precursor solution is 0.02M-0.1M, seal it with a plastic wrap, put it into a thermostat for heating reaction, the reaction temperature is 60°C-100°C, and the reaction time is 2- After 6 hours, after the reaction was completed, the temperature was lowered to room temperature, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com