Preparation method for inflaming retarding ethylene propylene rubber tent cloth

A technology of ethylene-propylene rubber and shed cloth, which is applied in the field of rubber materials, and can solve problems such as the decline in process performance and the difficulty in calendering of thin products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

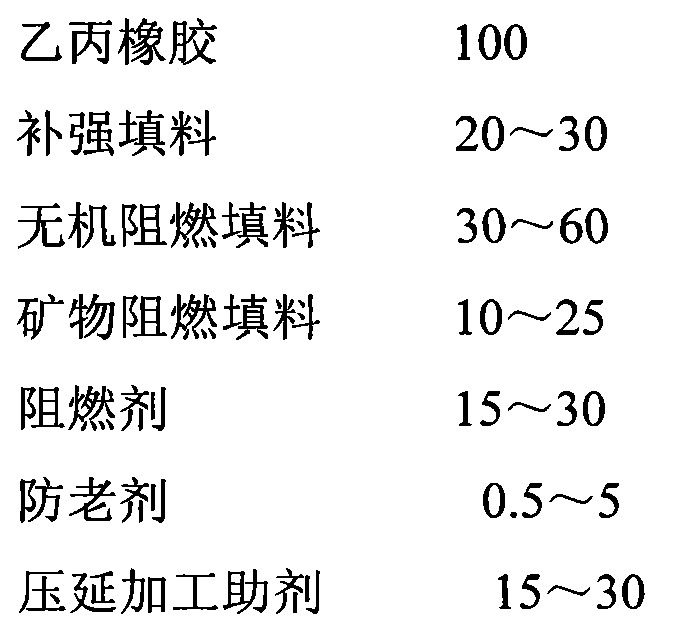

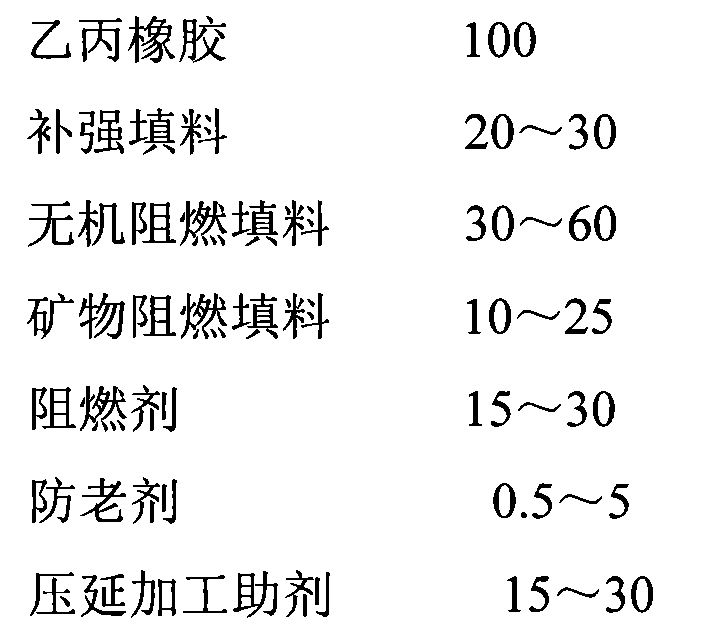

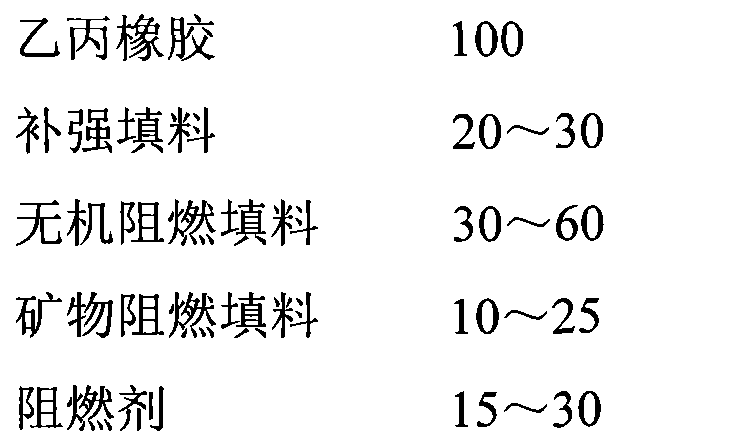

[0034] The preparation method of this flame-retardant ethylene-propylene rubber tarpaulin is one of the following, preparation method (A)

[0035] (1) Put each component of the flame-retardant ethylene-propylene rubber into the internal mixer according to the mass fraction, wherein:

[0036]

[0037]

[0038] Banbury at 80-110°C for 15-25 minutes, roll up and set aside;

[0039] (2) The rubber material after banbury mixing is re-mixed on the double-roller rubber mixer for 5-10 minutes, and rolled up and removed. The roller temperature of the calender is kept between 35°C and 50°C, start the calender, and place the re-milled film directly between the 1# and 2# rollers and between the 3# and 4# rollers of the four-roller calender. After the rubber material is completely covered on the surface of 2# and 3# rollers, the reinforcing fabric is placed flatly between the 2# and 3# rollers of the calender in the direction of glue feeding, and double-sided glued to form a rubber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com