Flexible polishing sheet and production method thereof

A flexible polishing and manufacturing method technology, applied in the direction of manufacturing tools, grinding/polishing equipment, abrasives, etc., can solve the problems of high polishing cost, low polishing efficiency, waste of polishing materials, etc., to increase the grinding and polishing area and expand the scope of use , Improve the effect of grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] This embodiment is a manufacturing method for making a No. 1500 polishing sheet according to the particle size requirements, and this manufacturing method corresponds to the first technical solution of the present invention.

[0036] 1) Cut the non-woven fabric according to the specifications, and then press it on a hot press at a temperature of 150°C and a pressing time of 8 minutes, and take it out for use;

[0037] 2) preparation of polishing abrasive material glue: by mass percentage, W7 (or W10) diamond micropowder 20%; Epoxy resin glue 50%, other materials 30%; By mass percentage, each material in described other materials accounts for polishing grinding The percentages of the total mass of the material glue are: W5 silicon carbide 10%, aluminum oxide 5%, zinc oxide 10%, cryolite 5%; each raw material is weighed according to the above ratio, and the powder is first mixed evenly, and then added to the glue Stir evenly in the liquid, if the glue is thicker, you can ...

Embodiment 2

[0041] This embodiment is a manufacturing method for making a No. 100 polishing sheet according to the particle size requirement, and this manufacturing method corresponds to the second technical solution of the present invention.

[0042] 1) Prepare the polyester fiber material;

[0043] 2) preparation of polishing abrasive material glue: by mass percentage, 80 / 100 diamond powder 10%; polyurethane glue 50%, other materials 40%; each material in the other materials accounts for the percentage of polishing abrasive material glue total mass respectively For: W63 silicon carbide 20%; magnesium oxide 10%, silicon dioxide 7%, graphite 3%. Weigh each raw material according to the above ratio, wherein the powder is firstly mixed evenly and then added to the glue and stirred evenly. If the glue is thicker, a proper amount of diluent can be added to prepare it to obtain a polishing abrasive glue, which is ready for use;

[0044] 3) Weigh the polishing abrasive material glue and the po...

Embodiment 3

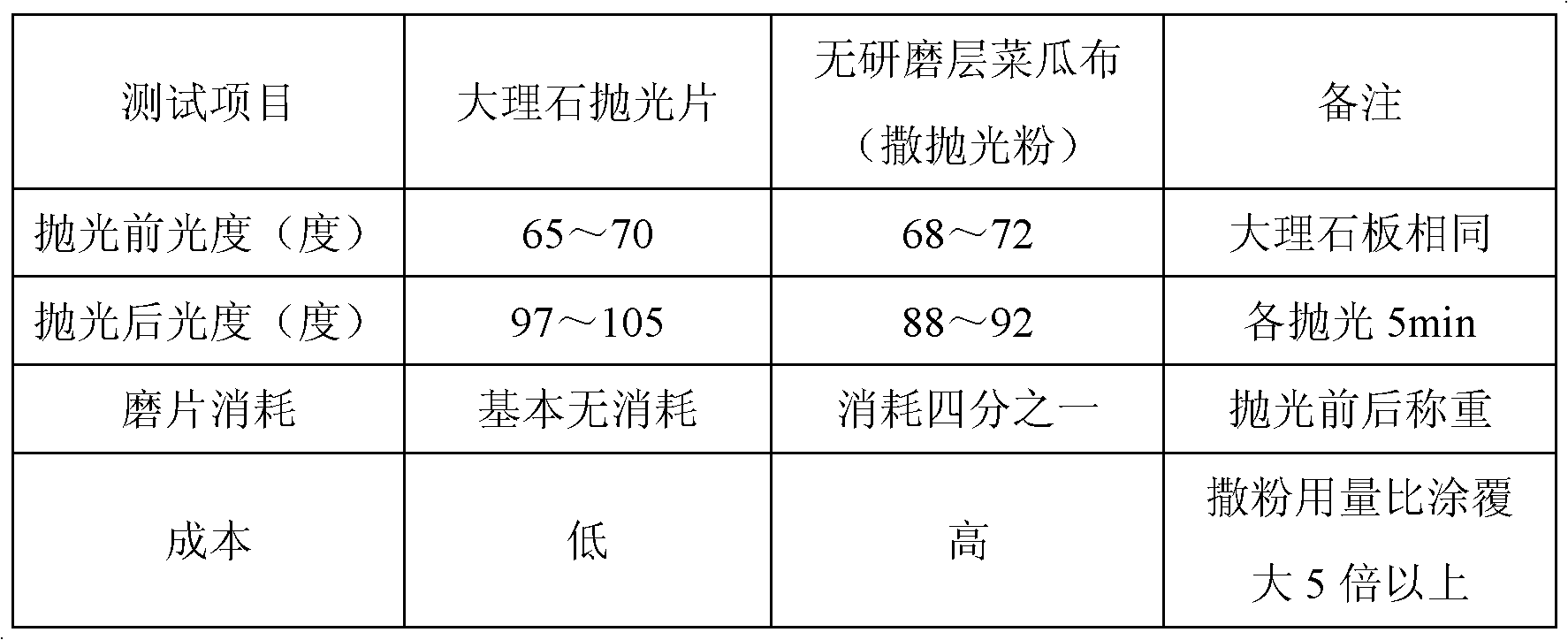

[0047] This embodiment is a manufacturing method for making a marble (or granite) polishing sheet, and the manufacturing method corresponds to the second technical solution of the present invention.

[0048] 1) Prepare the polypropylene fiber material;

[0049]2) preparation of polishing abrasive material glue: by mass percentage, ultrafine diamond micropowder 5%, polyvinyl alcohol glue 50%, other materials 45%, described other materials are marble (or granite) polishing powder); according to the above Proportionally weigh each raw material, mix the powder evenly and then add it to the glue solution and stir evenly to obtain a polishing abrasive material glue solution for use;

[0050] 3) Weigh the polishing abrasive material glue and the polypropylene fiber material according to the mass ratio of 75:25 and mix them evenly;

[0051] 4) Then pour into the mold and heat press to solidify at a temperature of 130° C. for 30 minutes. After demolding, it is made into a marble (or g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com