Novel welding rod and preparation method thereof

A welding rod and a new type of technology, applied in the field of welding rod and its preparation, can solve the problem of not being able to meet the requirements of emergency repair on the battlefield and emergency rescue of civil facilities, and achieve the effect of reducing the gap and gas volume, excellent mechanical properties, and convenient welding operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

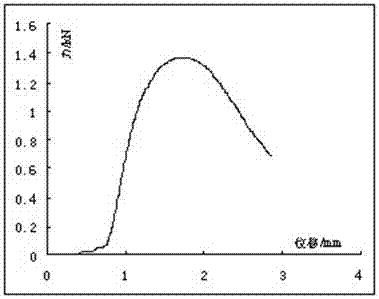

Embodiment 1

[0042] A novel welding rod is made of the following components by weight:

[0043] nitrocellulose 2 parts

[0045] Aluminum powder 15 parts

[0046] 3 parts silicon dioxide

[0048] 1 part calcium fluoride

[0049] 0.5 parts of diphenylamine.

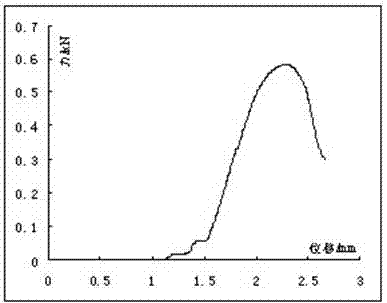

Embodiment 2

[0051] A novel welding rod is made of the following components by weight:

[0052] nitrocellulose 20 parts

[0054] Iron oxide 7 parts

[0055] Aluminum powder 7 parts

[0056] Silicon dioxide 6 parts

[0058] 4 parts calcium fluoride

[0059] 1 part diphenylamine.

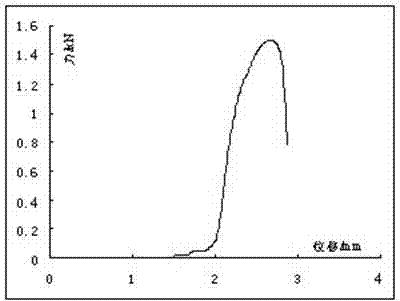

Embodiment 3

[0061] A novel welding rod is made of the following components by weight:

[0062] nitrocellulose 10 parts

[0063] Copper oxide 40 parts

[0064] Iron oxide 15 parts

[0065] Aluminum powder 10 parts

[0066] 4 parts silicon dioxide

[0068] Calcium Fluoride 2 parts

[0069] 2 parts diphenylamine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com